Picture of the month

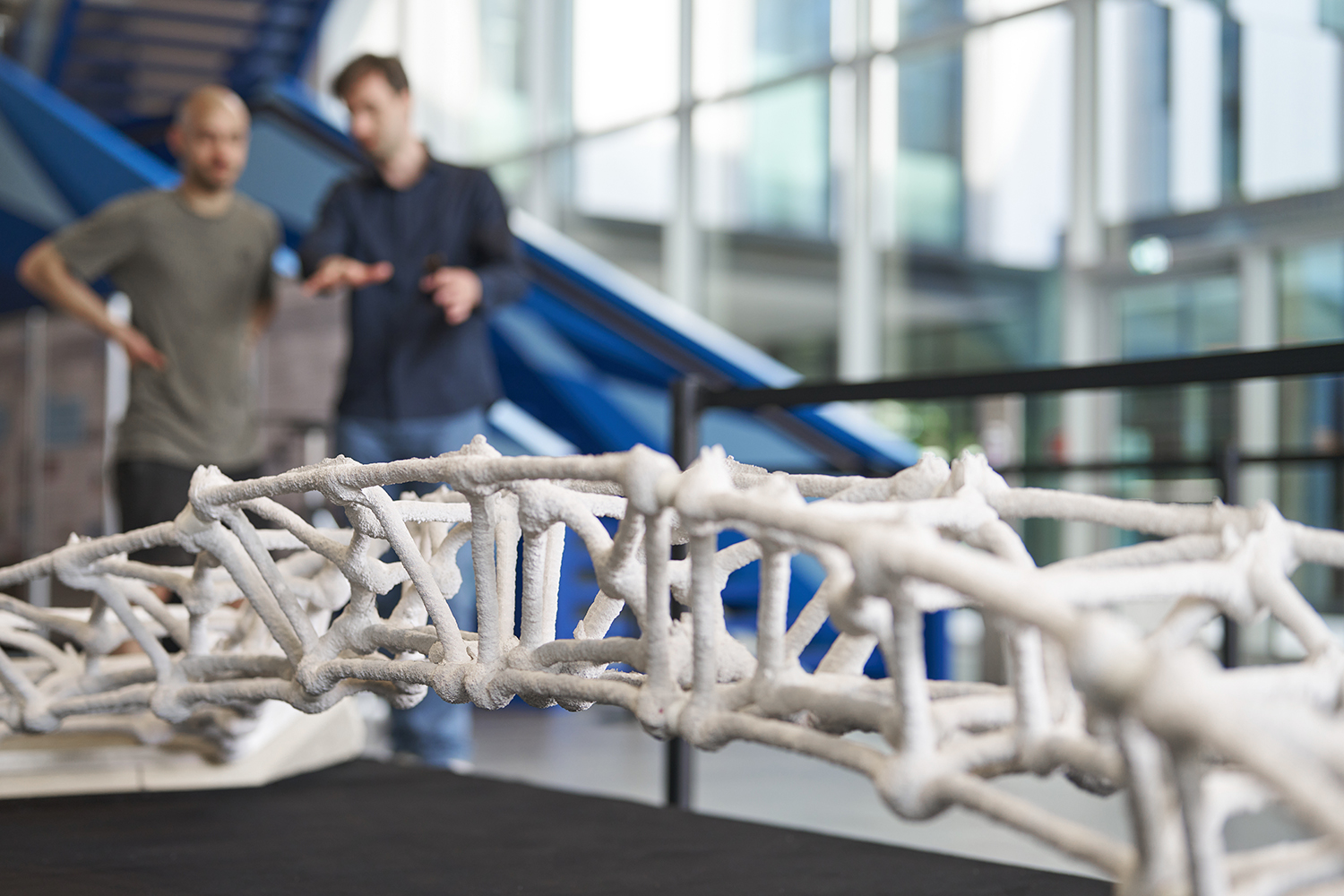

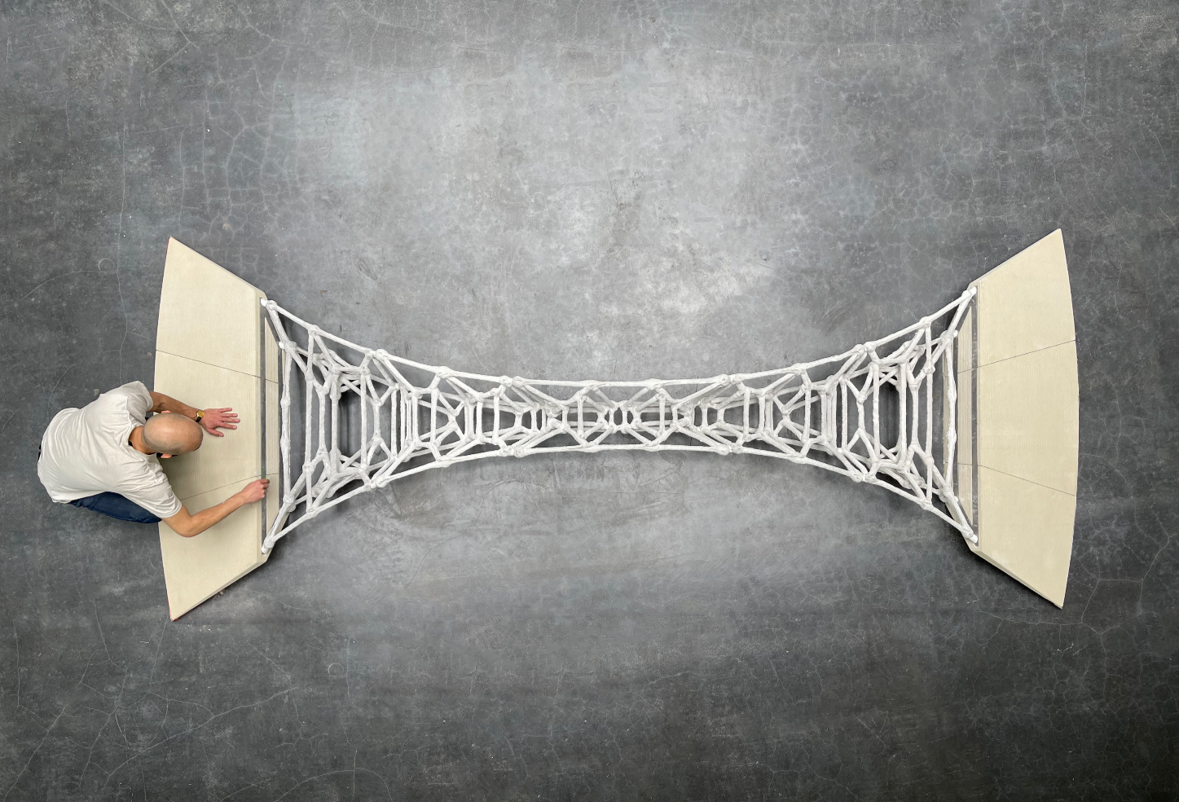

3D printed filigree bridge

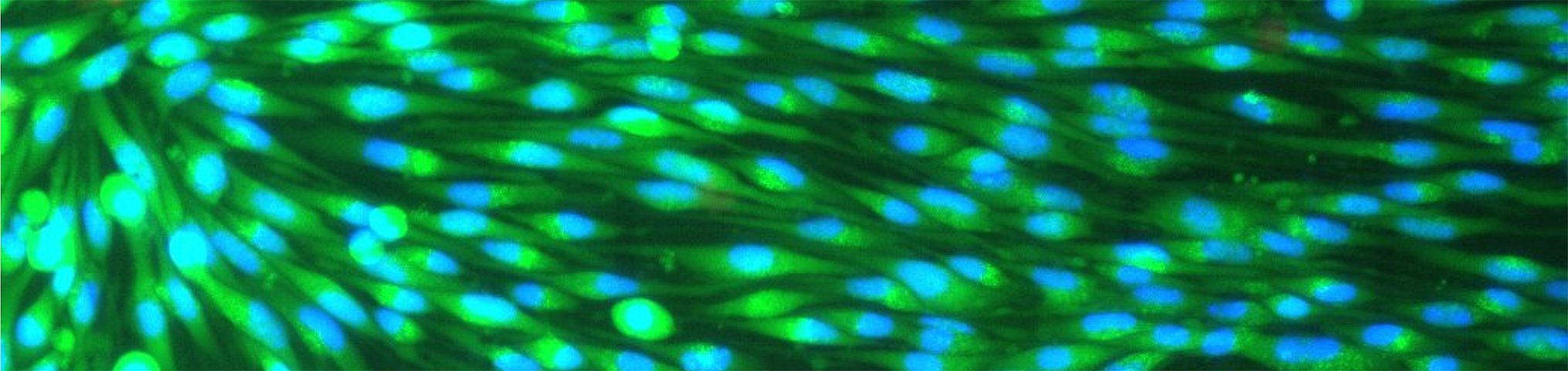

Could this be the bridge of the future? Filigree, light, material-efficient? In the Collaborative Research Centre “Additive Manufacturing in Construction (AMC)” of TU Braunschweig and TU Munich, scientists have produced the first bridge prototype using a special 3D printing process. “Injection 3D Concrete Printing”, developed and patented at TU Braunschweig, enables lightweight structures that were previously impossible with concrete.

Die filigrane Brücke wurde mit The filigree bridge was created by Injection 3D Concrete Printing. Picture credits: AMC/Julia Bergemeister

Additive manufacturing processes mainly focus on layer-by-layer 3D printing techniques, which are usually applied horizontally. However, these processes are limited for geometrically complex structures. “Injection 3D Concrete Printing”, on the other hand, offers completely new possibilities for form finding and 3D path planning. The component can also be built up three-dimensionally in space. This makes it possible to achieve a lightweight, resolved construction method more familiar from wood or steel.

In this 3D printing process, scientists robotically inject a strand of concrete into a non-hardening carrier fluid. The strand of concrete must remain in a stable position. The carrier fluid must therefore be perfectly matched to the concrete and the robot-controlled process in order to hold the material in the desired position. This support fluid can be removed later, leaving the filigree structure in place.

For the prototype of the bridge, five segments were printed, which were then assembled by the scientists. Picture credits: AMC/TU Braunschweig

Bridge exhibited at Architecture Biennale

To accommodate the limited working space of the robot arm, the original bridge had to be divided into five segments. These individual segments were then produced using the I3DCP process. Once the five bridge segments, the joints and the two support feet had been successfully 3D printed, they were assembled. The scientists took great care to ensure that each segment fitted seamlessly into the neighbouring segments to create a unified and robust structure.

The bridge caused a stir at last year’s Architecture Biennale in Venice. The structure was part of the “Time Space Existence” exhibition at the European Cultural Centre (ECC).

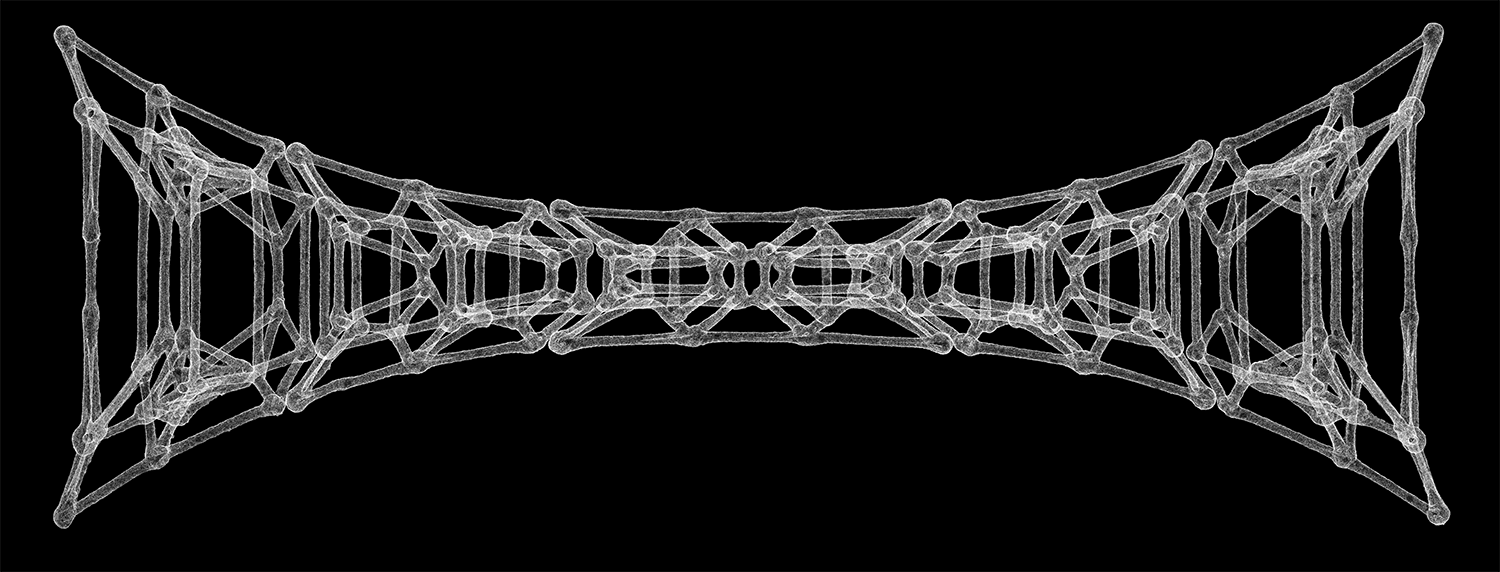

3D scan of the bridge. The bridge’s maximum load-bearing capacity exceeds its own weight by a factor of 20. Picture credits: AMC/TU Braunschweig

The prototype bridge is 4.20 metres long, 50 centimetres high and 1.80 metres wide at its widest point. Its total weight is approximately 312 kilograms. The bridge’s maximum load-bearing capacity exceeds its own weight by a factor of 20, demonstrating the potential of “Injection 3D Concrete Printing” for the construction of lightweight concrete infrastructure. In order to produce larger load-bearing objects, the scientists need to integrate reinforcement and nodes for a stronger structure.

The following researchers are involved in the project: Yinan Xiao, Aileen Vandenber, Osman Zhini, Dr. Patrick Ole Ohlbrock, Prof. Dr. Pierluigi D´Acunto, Prof. Dr. Norman Hack, Prof. Dr. Harald Kloft, Prof. Dr. Dirk Lowke und Prof Dr. Inka Mai.

About the Collaborative Research Centre AMC:

The DFG-funded Collaborative Research Centre TRR 277 “Additive Manufacturing in Construction” (AMC) of TU Braunschweig and TU Munich aims to play a key role in shaping the transformation of the construction industry towards a digital and sustainable future. The focus is on the use of 3D printing technology (additive manufacturing) to develop resource-saving, low-emission and economical construction methods. Complex research questions relating to materials, process engineering, digital process control, modelling, design and construction will be examined holistically by scientists from the fields of Civil Engineering and Mechanical Engineering.

Further information: www.amc-trr277.de

Submit proposals

You photograph yourself and would like to submit a picture? We are looking forward to your suggestions! Your picture should meet the following conditions:

- Image size: min. 2030px wide and 480px high

- Copyrights: You own the copyrights to the image and are willing to transfer the unrestricted rights of use to us free of charge.

- Right to your own image: If persons are visible in your photo, they must agree to the publication of the image.

- Corporate Design: Collages, extreme perspectives or alienations are not allowed in the central visual language of Technische Universität Braunschweig. You can read more about this on our Corporate Design website.

- Description: Tell us in three sentences what can be seen on your picture and where it was taken.

Does everything fit? Then send us your photo with the subject “Picture of the month” to presse@tu-braunschweig.de. We reserve the right to decide which photos to publish.

Pictures of previous months

Picture of the month March 2024

Flying sparks during laser sintering of ceramic solid electrolytes. Photo credit: Houssin Wehbe/Institute of Joining and Welding Technology/TU Braunschweig

In order to meet the growing demand for battery cells for electromobility and electronic devices such as smartphones and tablets, batteries and their production technologies need to be constantly developed. The picture of the month shows a snapshot of sparks during laser sintering of a ceramic solid electrolyte – an innovative concept for a new material to make lithium-ion batteries significantly more powerful and safer. Read more

Picture of the month February 2024

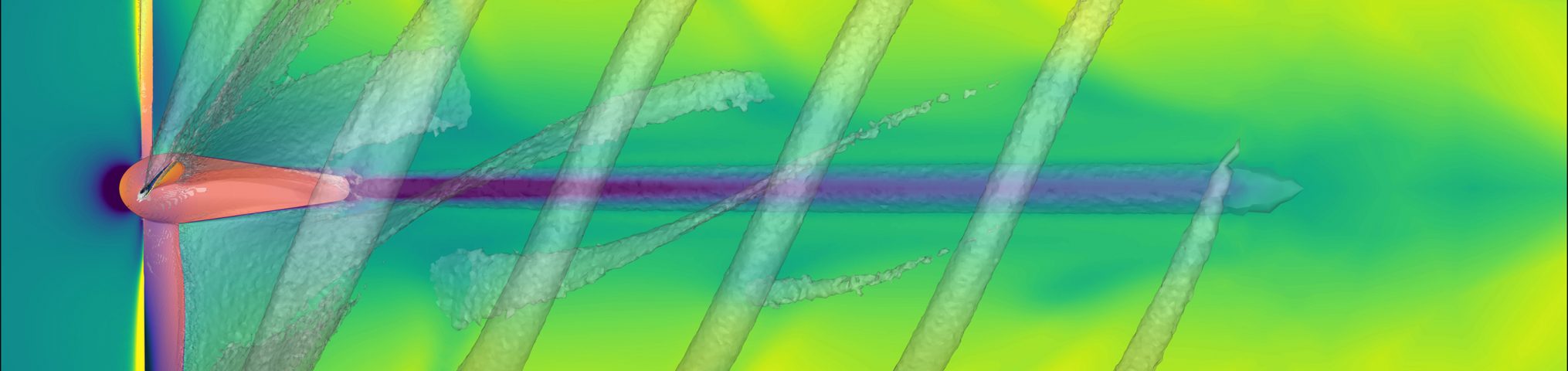

Schematic representation of a novel propeller with a typical helical wake. Picture credits: Bastian Kirsch/TU Braunschweig

The image was created as part of a project in the SE²A Cluster of Excellence. The aim is to understand the interaction between propellers and wings in new and future aircraft configurations. To do this, it is first necessary to know the aerodynamic properties and characteristics of the wing and propeller. The propeller is a design specifically created for a future aircraft with multiple propellers per wing – up to five per side. Read more

Picture of the month January 2024

Northern lights in Sweden, captured during a geophysical field campaign in 2023. Picture credits: Madhuri Sugand

A team of researchers from Technische Universität Braunschweig conducted a geophysical study of permafrost bogs in northern Sweden. As well as providing a lot of valuable data, the trip also left some beautiful impressions. Madhuri Sugand, for example, photographed a natural spectacle in the sky – the aurora borealis. Read more

Picture of the month December 2023

Fire test with timber constructions and sustainable insulation materials at the ZeBra Center of Fire Safety Research. Picture credits: Kristina Rottig/TU Braunschweig

Wood and insulating materials made from renewable raw materials will be increasingly used as building materials in the future due to their resource efficiency and CO2 storage properties. The disadvantage is that these materials are flammable. Therefore, wooden structures and insulation materials made from renewable raw materials need to be designed to be fireproof in order to prevent the spread of fire – for example, caused by a burning Advent wreath. Our picture of the month for December gives an insight into the research carried out at the ZeBra Center of Fire Safety Research. Read more

Picture of the Month November 2023

The display glasses from the Collection on the History of Pharmaceuticals contain pharmaceutical-chemical and mineral substances that were used as medicines. Picture credits: Anette Marquardt/TU Braunschweig

It is no coincidence that the glasses in our picture of the month are very colourful. They contain pharmaceutical-chemical and mineral substances that were used as pharmaceuticals. The Greek word for “pharmaceutical” (pharmakon) contains not only “poison” but also “colour” as a secondary meaning. The sight glasses come from the Pharmaceutical History Collection (Schneider Collection) of TU Braunschweig, which is looked after by the Department of the History of Science and Pharmacy. Read more

Picture of the Month October 2023

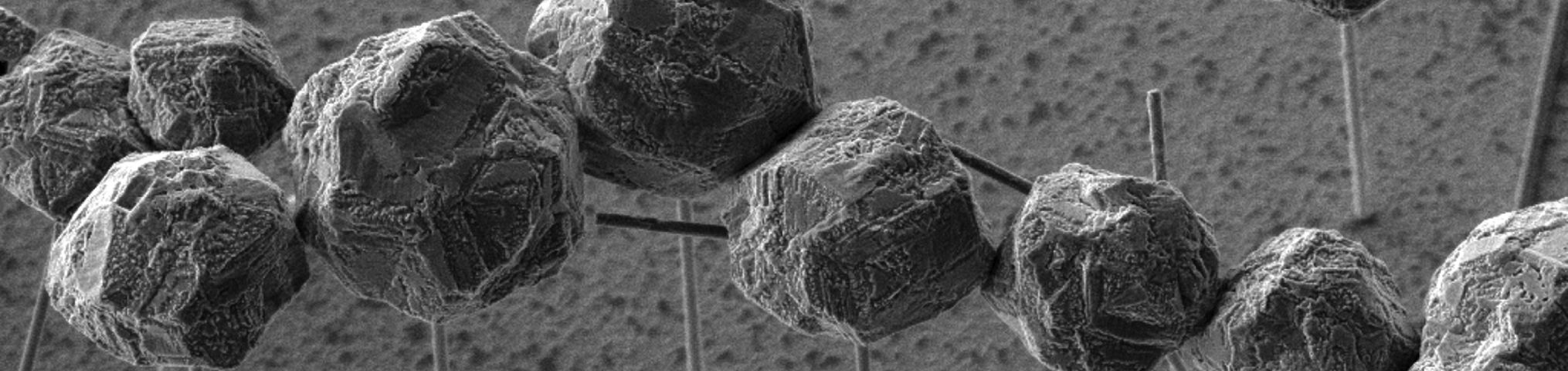

Becoming chestnut animals by accident: Nanowires with contacting surfaces at the tip. Picture credits: Maximilian Vergin/TU Braunschweig: Maximilian Vergin/TU Braunschweig

A walk on a golden autumn day can be a lasting delight. For when cold rain drums against the windows on a grey day, the chestnuts collected during the walk and a few toothpicks can be used to make caterpillars, deer and co. Maximilian Vergin from the Institute of Semiconductor Technology at the TU Braunschweig had neither chestnuts nor toothpicks at hand. But he did have the know-how to produce microscopic nanowires from metal, complete with jewellery-like tips. What chance has concocted into nano chestnut animals is now our picture of the month for the fall. Read more

Picture of the Month September 2023

Our picture of the month is not the new album release of the TU Braunschweig, but shows microscopic lenses from the LENA research centre. Like a magnifying glass, the micro-lenses have to be the right distance from the object of observation to see sharply. Their advantage: they get so close that even objects that are not visible with other light microscopes become visible. We received our picture of the month from scientific partners at the Physikalisch-Technische Bundesanstalt (PTB). They are checking whether the necessary tricks also work. Read more

Picture of the Month August 2023

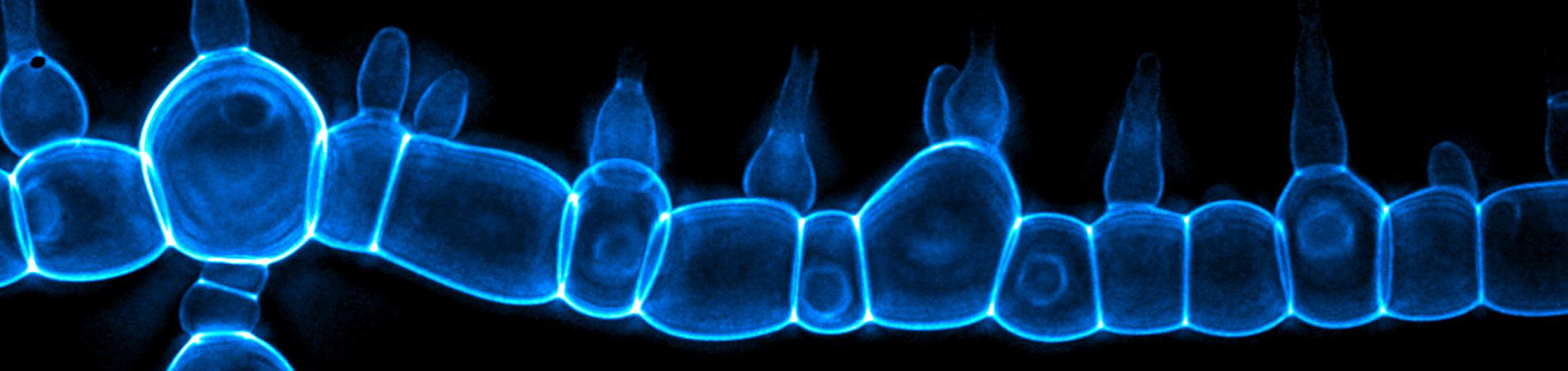

Mutated hyphae of the mould Neurospora crassa (Roter Brotschimmelpilz), which grow strongly branched due to the modification of the gene cot-1. Genetically modified strains provide a better understanding of fungal cells. Photo credit: Lucas Well/TU Braunschweig

Mushrooms are real all-rounders. On the one hand, they produce medicinal substances such as penicillin and enrich our food supply. On the other hand, they can also be dangerous for humans. Experts believe that infections with pathogenic fungi such as Candida albicans and Candida auris will increase. In the worst case, such infections can be fatal. In order to better understand fungal pathogens, Lucas Well, a doctoral student at the Institute of Genetics, is researching the harmless mould Neurospora crassa (“Roter Brotschimmelpilz“). Genetically modified strains, such as those shown in our picture of the month, provide a better understanding of fungal cells. Read more

Picture of the Month July 2023

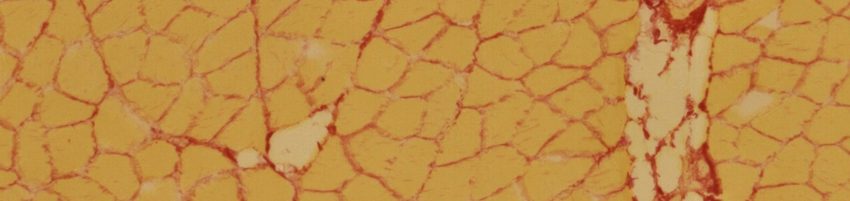

Typical histological muscle tissue sections – here of a rabbit – prepared with Picro-Sirius red stain, collagen is stained red and muscle fibres are stained yellow. Scale: 300 μm. Photo credit: S.Kutschke/TU Braunschweig

Healthy muscle activity is vital, not only for movement, but for many important processes such as speaking, chewing and breathing. In diseases associated with muscle atrophy, the microstructure of skeletal muscles is significantly altered. The Institute of Mechanics and Adaptronics at Technische Universität Braunschweig is working on the experimental multiscale characterisation of skeletal muscles, which can be used, for example, to make predictions about possible muscular deficits in patients in order to initiate appropriate treatment measures. Multiscale modelling also makes it possible to avoid animal experiments. Read more

Picture of the Month June 2023

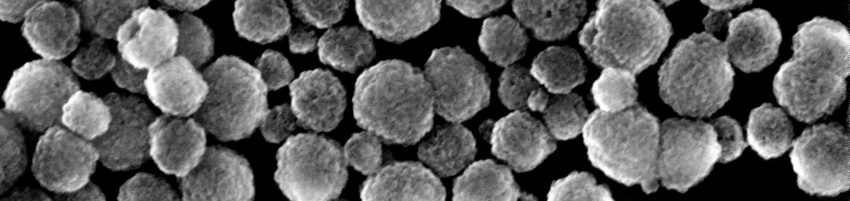

Image of the NaGdF4 particles doped by Eu3+ ions made with a scanning electron microscope. The examined particles show a rough surface, indicating that they are aggregates of primary nanoparticles. Picture credits: Bogdan Semenenko/iPAT

In 2022, the Institute of Jet Propulsion and Turbomachinery (IFAS), in cooperation with MTU Maintenance Biomarkers are needed to monitor processes in biological systems such as the human body. They can, for example, help to detect diseases and their progression at an early stage and to monitor the effectiveness of a certain treatment. Commonly, gold nanoparticles or organic dye molecules are used as biomarkers. However, their emission wavelengths cannot easily be tuned to mark different structures with distinct colours. Read more

Picture of the Month May 2023

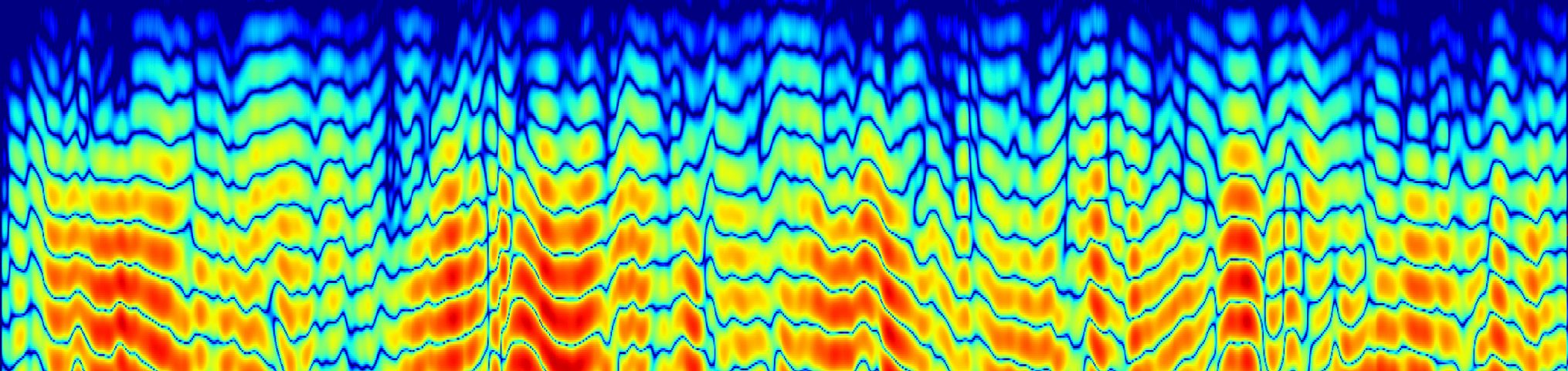

Forschungstriebwerk vom Institut für Flugantriebe und Strömungsmaschinen (IFAS): Bildnachweis: Jan Göing/TU Braunschweig

In 2022, the Institute of Jet Propulsion and Turbomachinery (IFAS), in cooperation with MTU Maintenance Hannover GmbH and the TFD of Leibniz University Hannover, successfully conducted two measurement campaigns with the research engine of TU Braunschweig. The measurement campaign consisted of two engine setups with different compressor blades. The data obtained is now being used in several research projects in the field of component fatigue as well as the construction of a digital twin of the engine. Read more

Picture of the Month April 2023

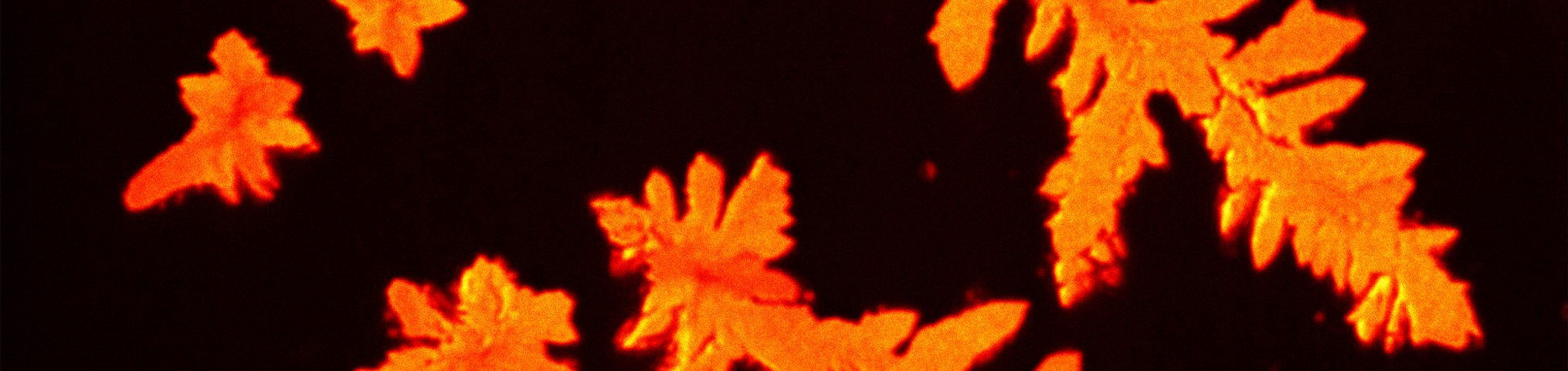

A work step on the way to single photon emitters: crystals of zinc phthalocyanine. Picture credits: Gunilla Harm/TU Braunschweig

At this point, the object in our picture of the month is still clearly visible. But the scientists at TU Braunschweig are making progress. As part of the QuantumFrontiers cluster of excellence, they have the vision of isolating individual molecules from the glowing orange crystals and selectively processing them. Attached to semiconductor surfaces, these molecules are given an incredibly tiny yet crucial task: to emit individual particles of light, photons. Read more

Picture of the month March 2023

You swallowed the tablet – and then what? How does the active substance get to where it is supposed to arrive in the body? If we know exactly how this works, medicines can be developed more efficiently and animal experiments can be reduced. To achieve this, the Institute of Microtechnology (IMT) is building chips in silicon technology that can be used to experimentally examine the absorption of active substances. Read more

Picture of the month February 2023

Concrete can absorb compressive forces, but when bending moments and tensile forces occur, the material can crack. To prevent this, reinforcement is used, for example in a base plate when building a house, often made of steel in the form of meshes or cages. Reinforcement is also necessary in 3D printing with cementitious materials in order to create load-bearing structures. One of the greatest challenges in additive manufacturing, because the good old “rebar”, as the reinforcing steel is also called, is not used here. Instead, steel structures are imprinted or filigree metal strands are carried along in the concrete strand. Scientists at TU Braunschweig are also developing textile-based reinforcement strategies in the Collaborative Research Center Transregio 277 “Additive Manufacturing in Construction”. Read more

Picture of the month January 2023

Wind power plays a crucial role in providing an environmentally friendly, reliable and affordable energy supply. One challenge in the year-round uninterrupted operation of wind turbines is the icing up of the turbine by supercooled water droplets. In winter, ice build-up due to low-hanging clouds or fog is also possible at German locations. This has a negative impact on electricity production and operational safety. In the Braunschweig Icing Wind Tunnel, scientists are investigating how ice build-up can be prevented or how de-icing can be simplified. Read more

Picture of the month December 2022

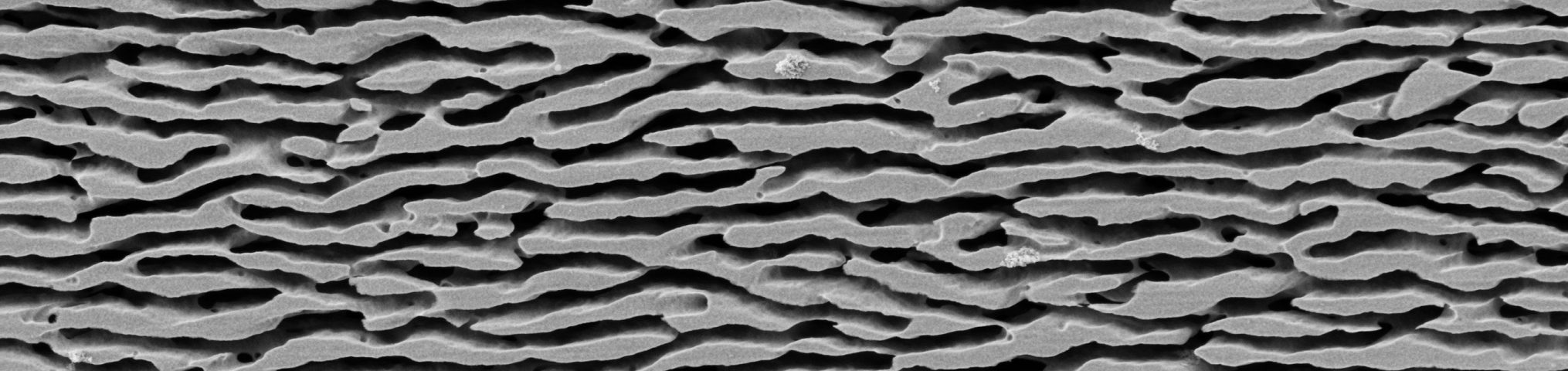

When metallic materials are exposed to stresses such as high temperatures and tensions over a long period of time, changes occur in their microstructure. In turbine blades, these lead to potential material damage, but researchers from the Institute of Materials Science are taking advantage of precisely this mechanism. They are using it to produce nanoporous membranes made of a nickel base superalloy that could be used in pharmaceuticals. What these membranes look like under the microscope is shown in our picture of the month. Read more

Picture of the month November 2022

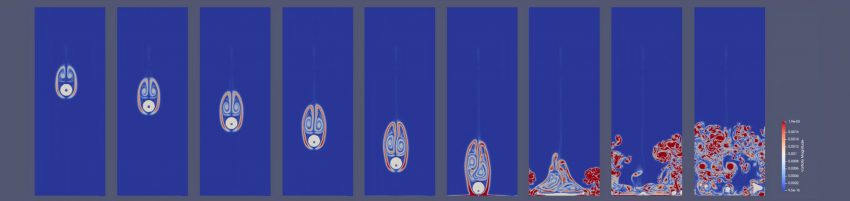

“Research in the process of becoming” – this is how professor Martin Geier describes his picture of the month. It shows an intermediate step on the way to a physically correct simulation of a falling concrete drop. The simulation should help to understand the behaviour of fluids with large density differences. This understanding can later be used to increase the stability of shotcrete structures. On the way to this goal, professor Geier’s team is still working on parameters such as viscosity and surface tension to adapt the simulation to real conditions. Read more

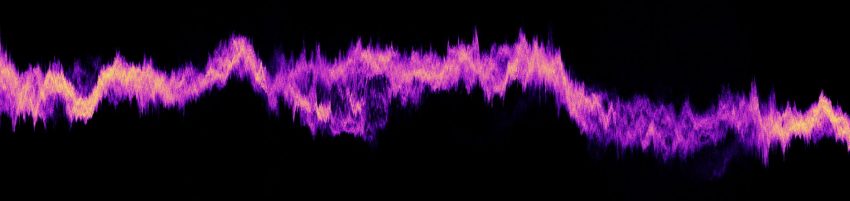

Picture of the month October 2022

From left to right: five seconds of dense fog. Our picture of the month shows a section of the wind lidar project of the Physikalisch-Technische Bundesanstalt (PTB). In this project, the team around Dr. Michael Eggert and Paul Wilhelm is constantly developing a system that sets new standards in remote wind measurements: PTB’s bistatic wind lidar. Although the fog image is rather a curious special case (the lidar can be used even at very low particle densities and clear visibility): In fog, the novel measuring instrument demonstrates its performance and resolution particularly impressively. Read more

Picture of the month September 2022

Whether heart valves, urinary bladders or tracheas: through tissue construction and tissue engineering, these organs have already been successfully replaced artificially in patients. Other organs, such as the stomach, are much more complex. They consist of different tissues, different cell types and are also permeated by countless blood vessels. In order to improve the quality of life of gastric resection patients with a new stomach replacement therapy, the biomechanics laboratory is researching the mechanical properties of a healthy stomach on different size scales. Read more

Picture of the month August 2022

Oregano makes people happy and insects too! – that could be the motto for our picture of the month. Oregano is an indispensable spice in Italian cuisine, but it also has numerous positive properties for humans and the environment. In the Medicinal Plant Garden of the Institute of Pharmaceutical Biology at Technische Universität Braunschweig, you can find not only the well-known Mediterranean oregano but also the native wild oregano. Read more

Picture of the month July 2022

Not all electron microscopes are the same. Since the first set-up in 1931, researchers have been working at great expense to achieve ever higher resolutions. The most powerful electron microscope at the TU Braunschweig, the TEM, is therefore completely sealed off from mechanical vibrations (such as trams rattling past) and magnetic fields (such as the earth’s magnetic field) at the LENA research centre. Read more

Picture of the month June 2022

UV light has a wide range of applications: Depending on the wavelength and energy intensity of the light, UV LEDs can sterilise surfaces and water, make tomatoes grow particularly tasty or be used in dermatology for skin treatments. However, the efficiency of the “invisible” UV LEDs can still be improved. A team at the Institute of Semiconductor Technology is researching this. Their approach: The crystal layers within the UV LEDs are laid out three-dimensionally as a microstructure instead of as a two-dimensional disc, as was previously the case. Analyses under the electron microscope – as seen here in the Picture of the Month June – indicate a high efficiency of the UV LEDs constructed in this way. Read more

Picture of the month May 2022

What role does a street play in the overall network? And how do the individual segments of the urban street network relate to each other? This is what the SpACE Lab at ISU – Institute for Sustainable Urbanism at Technische Universität Braunschweig is working on. The “Spatial Analytics and Crossdisciplinarity Experimentation Lab” develops data-driven methods and solutions for human centric sustainable mobility. In the work shown here, the interdisciplinary team focuses on developing a network-based user-centric categorisation of street segments. This can be used, for example, to make statements about the quality of the network for different street users. Our picture of the month May visualises this categorisation to get a better understanding of the Urban Street Network.

Picture of the month April 2022

Our picture of the month April 2022 does not show a landscape on a distant planet, but a special fabric. The piece of fabric, which measures about four by two centimetres, can be found in various places on the inside of a so-called ECG T-shirt. It is used to measure an electrocardiogram (ECG) without the patients noticing anything. The Peter L. Reichertz Institute for Medical Informatics (PLRI) at Technische Universität Braunschweig and the Medizinische Hochschule Hannover is using this to research the future of health monitoring. Read more

Picture of the month March 2022

The picture shows a scan of a ground-penetrating radar. It shows unchanging objects in the ground. If the data is combined with the position from laser measurements, a map developed from this information can be used for the navigation of mobile robots. A laser or cameras would then no longer be necessary. The Institute for Mobile Machines and Commercial Vehicles is conducting research on this in the “LoBaBo” project. Read more

Picture of the month February 2022

Here they are, the first early bloomers in the Botanical Garden poking their little heads out. The native winter aconite is one of the quickest. With its bright yellow flowers, it already has its big moment in February. Under the still leafless trees, the small tuberous flowers form dense flower carpets and set bright colour accents. Reason enough to take a closer look at the plants in our picture of the month. Read more

Picture of the month January 2022

For the researchers, the headspace GC/MS system shown in the Picture of the Month is an eagerly awaited addition for battery analysis. It was purchased for BLB diagnostic line. It will now make it possible to better understand battery aging and develop longer-lasting batteries. It is a system for the analysis of liquid electrolytes or soluble surface deposits in the components of a battery. Read more