Picture of the month: Organ-on-Chip Platform The Institute of Microtechnology is developing chips to research better intake of active substances in the body

You swallowed the tablet – and then what? How does the active substance get to where it is supposed to arrive in the body? If we know exactly how this works, medicines can be developed more efficiently and animal experiments can be reduced. To achieve this, the Institute of Microtechnology (IMT) is building chips in silicon technology that can be used to experimentally examine the absorption of active substances.

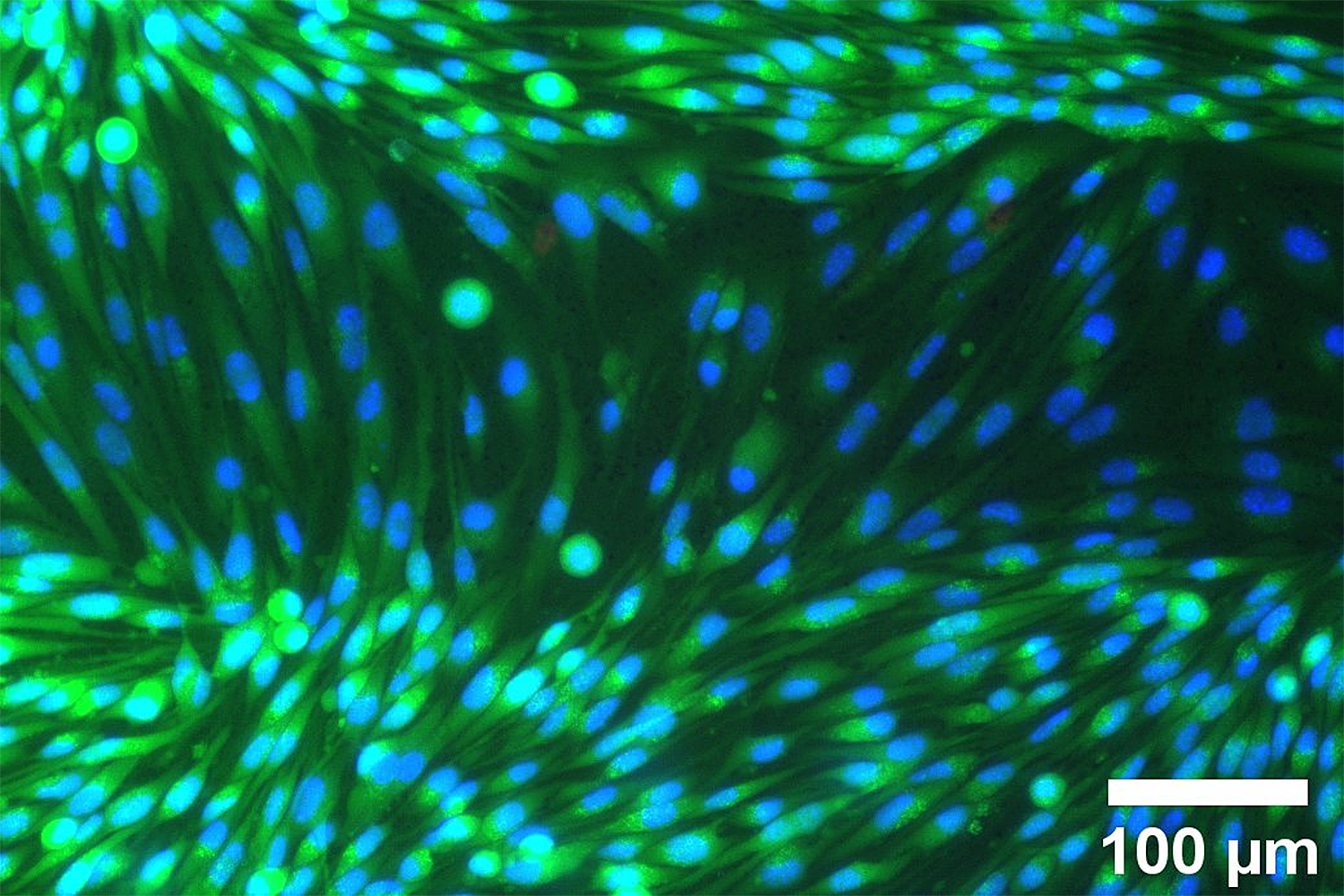

Stained human endothelial cells (cell layer on the inner surface of blood and lymphatic vessels that allow active substances from medicines to pass through) cultivated in the chip in flowing medium. Picture credits: Bo Tang, Victor Krajka/TU Braunschweig

The active substances from medicines have to pass through the endothelium, i.e. the cell layer on the inner surface of blood and lymph vessels. This is how they enter the patient’s body and are then distributed. However, the endothelial tissue represents a transport barrier for the active substances. In order to better understand these processes, scientists at the Center of Pharmaceutical Engineering (PVZ) want to observe them in vitro, i.e. under experimental conditions. This is made possible by a novel organ-on-chip platform with MEMS processing at wafer level, which the Institute of Microtechnology is working on.

A “machine” in a very small space

MEMS stands for Micro-Electro-Mechanical Systems and describes the combination of mechanics and electronics in a very small space, in this case at wafer level, i.e. on the scale of silicon chips. MEMS are therefore small machines or sensors. For the study of endothelial tissue, the chips are equipped with an ultra-thin nanoporous membrane and a bioimpedance sensor.

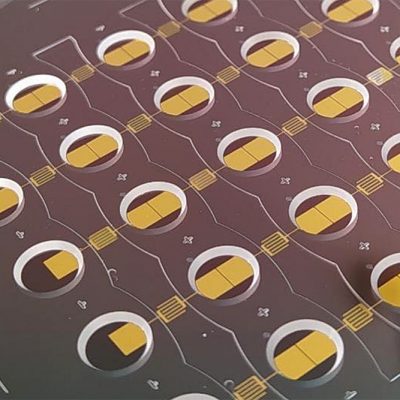

- Organ-on-chip systems in the development process in the clean room during the bonding of glass and silicon structures. Picture credits: Bo Tang, Victor Krajka/TU Braunschweig

- Organ-on-chip systems: Finished chip (1cm x 1cm) with electrodes for impedance spectroscopy on a 500 nm thin membrane with nanopores. Picture credits: Bo Tang, Victor Krajka/TU Braunschweig

The chips consist of two channels separated by a permeable membrane. One channel represents the interior of the vessel, the other the surrounding tissue. Cells grow on this membrane, thereby forming their barrier function. The denser the cells grow, the higher the barrier function.

The bioimpedance sensor is integrated on the chip, or more precisely, on the ultra-thin nanoporous membrane on which the cells will grow. An alternating current is applied to measure the impedance. Depending on the resistance or frequency, a distinction can be made between cell density or cell-cell contact strength. This is a very useful method to determine the biological barrier integrity during drug treatments in real time.

The entire project benefits from the multidisciplinary collaboration between the working groups of Andreas Dietzel, Stephan Reichl, Iordania Constantinou, which takes place at the Center of Pharmaceutical Engineering (PVZ).