How Long is a Picometer? – The View of a Single Atom High resolution microscopy in LENA

As long as it has to be accurate to the millimetre, the domestic folding rule will do. It is more complicated, however, to divide a millimeter into a million nanometers. These subtleties of our measuring units are decided at the limit of what can be measured. This is exactly where the LENA (Laboratory for Emerging Nanometrology) research centre at the Technische Universität Braunschweig comes in. In order to continue research at this limit in the future, Professor Andreas Hangleiter and his team from the Institute of Applied Physics are currently installing a new electron microscope that resolves at the atomic level.

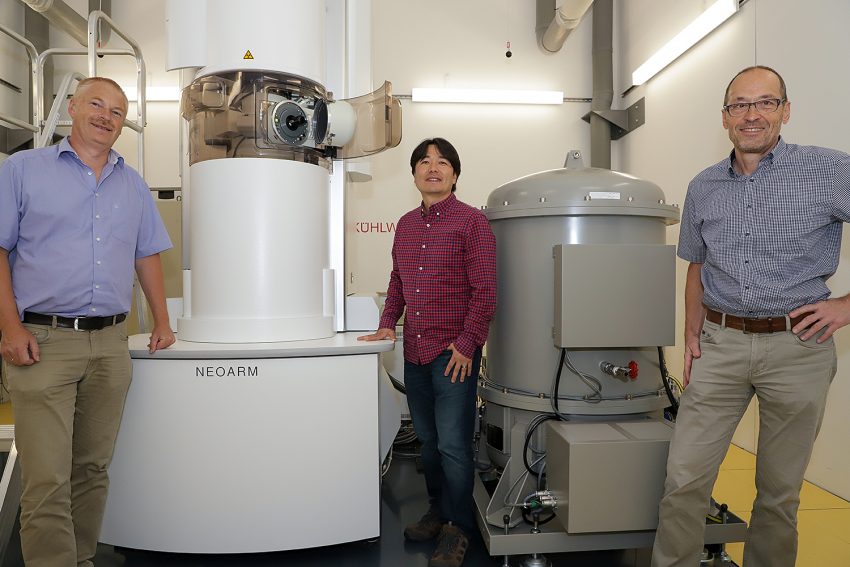

The team behind the HR-TEM: (from left) Dr. Heiko Bremers, Dr. Daesung Park and Professor Andreas Hangleiter. Not in the picture: Dr. Markus Etzkorn. Picture credits: Kristina Rottig/TU Braunschweig.

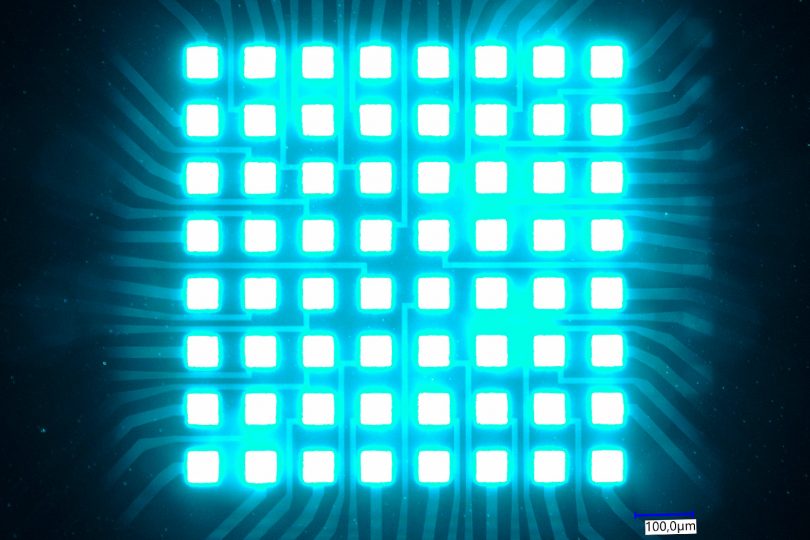

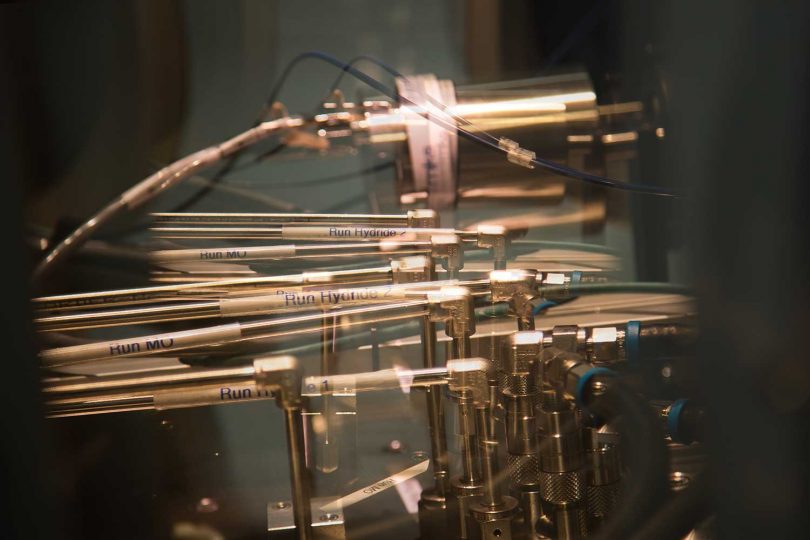

It is LENA’s largest and most expensive instrument: the high-resolution transmission electron microscope (HR-TEM). Professor Andreas Hangleiter’s team is still working on the final details of the setup and calibration. In the HR-TEM, high-energy electrons will soon be able to penetrate objects that are only a few nanometers in thickness. The goal is a resolution of 70 picometres (0.07 nm). With this, the researchers are working close to the current limit of resolution, the core of the Metrology research area. “With the HR-TEM we ‘see’ single atoms in crystals. We are particularly attracted to the tomographic approach. In the future we want to locate individual atoms in their three-dimensional arrangement,” explains Professor Hangleiter.

Surrounded by water, copper and aluminium

In addition to the price of 3.5 million euros, the HR-TEM places high demands on the laboratory. When the tram passes within 500 meters, vibrations and magnetic fields threaten the exact measurement. For this reason, the microscope stands on an air-sprung foundation weighing almost 50 tons and a seamlessly welded aluminium plate encloses the room from all sides. To additionally shield the earth’s magnetic field, the laboratory is surrounded by electric magnetic coils. They are directed in the opposite direction to the earth’s magnetic field, so that only the slightest magnetic field remains at the location of the microscope. The first tests show that the measures are necessary and even had to be extended: “When we tested the effectiveness of the protective measures, it became clear that the laboratory chairs are not ideal. The HR-TEM noticed as soon as someone swivelled on their chair. Now we upgraded,” says Professor Hangleiter.

Another protective measure caused some amazement: twice, craftsmen resorted to the drill while preparing the room for the electron microscope. When water began to flow out of the holes in the wall, they became suspicious. “Each material reacts differently to differences in temperature. So we need a constant climate to measure accurately and reproducibly. That’s why coolant flows through all the walls and prevents heat flows and temperature differences,” explains Professor Hangleiter. Since then, all surfaces have been provided with another safety measure: “Please do not drill!”.

The HR-TEM is expected to be ready for use in a few weeks. Then Professor Hangleiter’s team can fully concentrate on the search for atoms and their properties.