Picture of the month: Promising solid electrolytes for high-performance rechargeable batteries Laser beams for ceramic solid-state batteries

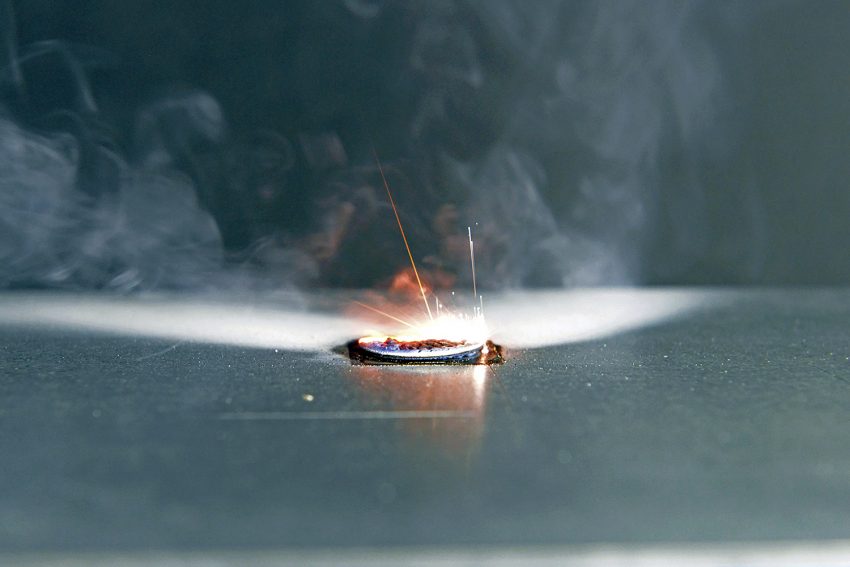

In order to meet the growing demand for battery cells for electromobility and electronic devices such as smartphones and tablets, batteries and their production technologies need to be constantly developed. The picture of the month shows a snapshot of sparks during laser sintering of a ceramic solid electrolyte – an innovative concept for a new material to make lithium-ion batteries significantly more powerful and safer.

Flying sparks during laser sintering of ceramic solid electrolytes. Photo credit: Houssin Wehbe/Institute of Joining and Welding Technology/TU Braunschweig

Improvements in capacity, energy density and safety compared to conventional lithium-ion batteries based on liquid electrolytes are important for the future generation of batteries. One promising cell concept is the solid-state battery, in which the flammable liquid electrolyte and separator are replaced by an ion-conducting ceramic solid.

Laser radiation for sintering

In order to compact the loose particles, this ceramic solid electrolyte must be subjected to heat treatment in the kiln. This process has been known for thousands of years and was used to produce the oldest known ceramic figurine, the Venus of Dolní Věstonice, over 25,000 years ago. Until now, however, the establishment of a competitive mass product has been doubted, as the sintering of the ceramic battery component in the kiln has process and material-related disadvantages.

The novel idea behind the success of ceramic solid-state batteries is the use of laser radiation for sintering. This process has the advantage of being non-contact, flexible and fast. However, the interaction mechanisms between the solid electrolyte and the laser radiation are still poorly understood. The image shows the sparks generated by the high energy input of the laser beam, which acts for a brief moment on the pre-compressed solid electrolytes.

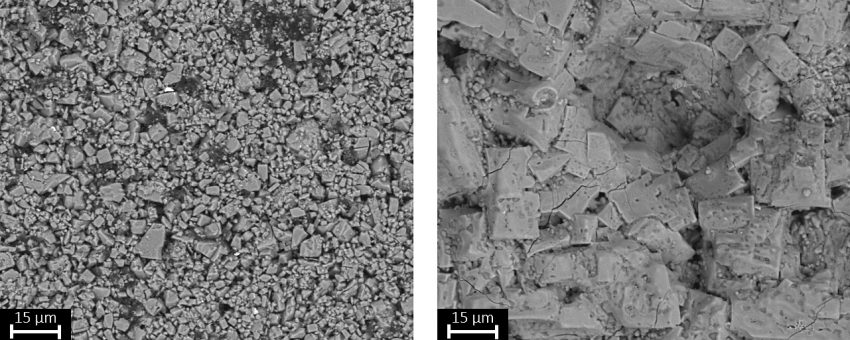

Microstructure of the ceramic in the unprocessed state (left) and after laser processing (right), photographed under a scanning electron microscope. Larger particles reduce the resistance and allow ions to migrate. Photo credit: Institute for Joining and Welding Technology/TU Braunschweig

The aim of the project at the Institute of Joining and Welding Technology is to improve the basic understanding and to develop a safe process in the long term. The first successful sintering has already been achieved, as evidenced by the microstructure showing particle growth. The institute is carrying out further investigations to verify its use in the battery.