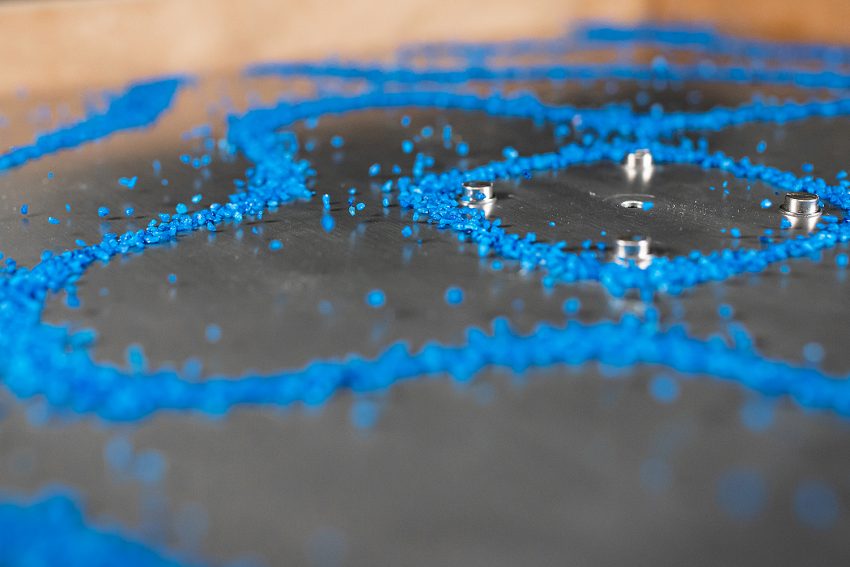

Picture of the Month: Chladni Figures In the acoustics lab: visualizing the vibration behavior of panels

How can you visualize the vibration behavior of plate structures without simulations and without laser measurement technology? With a relatively simple experiment. In the 18th century, vibration behavior was studied thanks to a discovery by the German physicist Ernst Florens Friedrich Chladni. The experiment is also on display for teaching purposes in the acoustics lab at TU Braunschweig, which works closely with various institutes and with the Cluster of Excellence SE2A. Sebastian Rothe, head of the “InALab Acoustic Engineering”, explains how the impressive patterns are created.

Making sand vibrate: Chladni figures generated in the acoustics lab at TU Braunschweig. Picture credits: Max Fuhrmann/TU Braunschweig

The vibration behavior of structures describes in which areas much or little vibration occurs at certain frequencies. Knowledge of this helps to avoid noise (low-noise design) or to set a desired vibration behavior (acoustic design). With the Chladni figures, it has been possible to visually assess the vibration behavior since more than 200 years ago.

“Today, we only use this experiment for teaching purposes, as it gives students an understanding of basic acoustics in a very vivid way. We can use it to make sound visible,” says Sebastian Rothe.

Patterns in the sand

But how can sound be made visible? To do so, the center of the plate is made to vibrate at a mono-frequency. “If a natural frequency of the plate is hit (resonance), the operating vibration mode is mainly determined by the associated natural mode. Put simply, standing waves with areas of high and low vibration amplitude form on the plate,” Rothe explains. While the sand is catapulted away in areas with high vibration amplitude, it collects in the areas with low vibration amplitude. In this way, the operating vibration modes can be made visible. Each resonant frequency has a characteristic operating mode shape. The resulting patterns are called ” Chladni figures”. Where these resonant frequencies lie depends on the geometry and material of the panel.

What is researched in the acoustics lab

The Acoustics Laboratory is concerned with the experimental characterization of the airborne and structure-borne sound behavior of solids. Mainly, structure-borne sound investigations and material characterizations are performed.

” For instance, we use laser measurement technology to measure the distribution of the sound velocity of surfaces of vibrationally excited structures and match it with simulation data, for example,” says Rothe.

Another important part, he says, is determining frequency-dependent material parameters such as damping (can a material dampen sound well or poorly?) or the elastic modulus of materials (how stiffly does a material react when subjected to force?). The absorption coefficient, i.e. how much sound is “swallowed”, as well as the flow resistance of porous media (e.g. metal foams, plastic foams) are also measured so that these data can in turn be used in simulations.

Broad cooperation at the TU

The Institute for Acoustics emerged from a research group at the Institute for Construction Technology (IK). ” Based on this tradition, we work closely with the IK,” says Rothe. The acoustics expertise is in demand. For example, there have already been projects with the Institute for Dynamics and Vibrations (IDS), the Institute for Materials (IFW), the Institute for Computational Modeling in Civil Engineering (IRMB), the Institute of Operating Systems and Computer Networks (IBR) and the Institute for Thermodynamics (IFT). “In addition, we are part of the Research Training Group 2075 and the Suresoft project, as well as embedded in various centers such as the NFF, NFL and MUSEN.”

Acoustic simulations in the cluster of excellence

The Cluster of Excellence SE2A at TU Braunschweig conducts research on sustainable aviation. Noise reduction is a central component of this. Two colleagues are working in the Cluster of Excellence to perform acoustic simulations on future aircraft concepts. One of them is working on the noise assessment of sound emissions in the vicinity of airports. Cooperation with DLR in Göttingen and Braunschweig allows a holistic view from the engine to the aircraft fleet. On the other hand, vibroacoustic simulations of the sound pressure level in the passenger cabin are set up to evaluate the acoustic progress of the new technologies. Close cooperation within the project also makes it possible to comprehensively consider various noise sources and details of aircraft configurations (e.g. with DLR Braunschweig, Institute of Jet Propulsion and Turbomachinery (IFAS), Institute of Aircraft Design and Lightweight Structures (IFL)).