Hydrogen Research at TU Braunschweig

The biggest challenge of the energy transition remains the transport and storage of renewable energies and their use in the heating and mobility sectors. One solution is the use of hydrogen technologies. Whether condensation phenomena in aviation, refuelling station systems for trucks, the transformation of the steel industry, cooperation with Australia, the Netherlands and Japan, a dedicated H2 Terminal or an interactive escape room: numerous institutes at Technische Universität Braunschweig are working on projects, innovation labs and the SE²A Cluster of Excellence to make hydrogen (H2) fit for the future. A selection.

Institute of Technical Chemistry

Led by Professor Mehtap Oezsaslan, the Institute’s Technical Electrocatalysis Laboratory is researching the optimisation of electrolysis for hydrogen production. In the project “Design of Nanostructured Noble Metal-Containing Chalcogenide Electrocatalysts for the Hydrogen Evolution Reaction”, the team is working with scientists from Dresden and the USA to improve the hydrogen production process. The Braunschweig researchers are also working on new affordable and durable electrocatalysts for electrolysis and fuel cells at the Japanese-German Green Hydrogen Material Laboratory. The research group is also involved in the Hydrogen Competence Centre (H2 Terminal) at the Braunschweig Research Airport. It models, simulates and tests holistic technologies along the hydrogen conversion chain in the real laboratory. They are also involved in the Water Electrolysis Innovation Laboratory (InnoEly), which is developing hydrogen electrolysis technologies.

Institute of Internal Combustion Engines and Fuel Cells

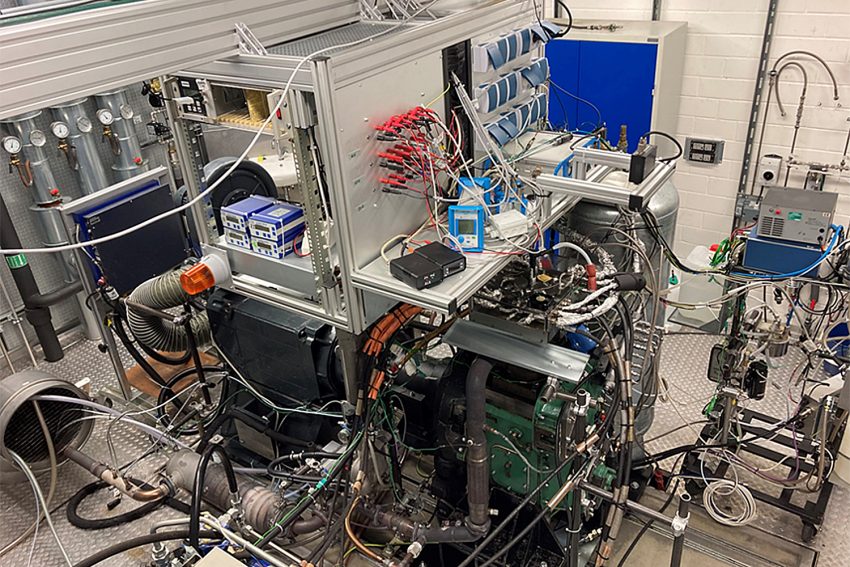

The Institute’s Internal Combustion Engines research focus, headed by Professor Peter Eilts, focuses on the development and research of combustion processes. For example, the H2-ICE-LOC project is working on the use of a hydrogen direct combustion engine to enable zero-emission shunting operations in rail freight transport in the future. In the innovation laboratory “Thermomanagement von H2-Tankstellen“ (THEWA) (Thermal Management of H2 Filling Stations), several institutes of the Automotive Research Centre Niedersachsen (NFF) are working with industrial partners to research the hydrogen filling stations of the future – especially for heavy goods vehicles.

As part of the “Sustainable Hydrogen Combustion Concepts” (WaVe) innovation laboratory, the Institute is working with other universities in Lower Saxony to implement hydrogen combustion using innovative measures to minimise emissions.

Test bench box with 1-cylinder commercial vehicle research engine at the NFF (WaVe). Photo credit: Marius Betz/Institute of Internal Combustion Engines and Fuel Cells

In the institute’s Fuel Cells research focus, a team led by Assistant Professor Michael Heere is investigating how to increase the power density and reliability of fuel cells. For example, the SE²A project “C6.1: Data-driven understanding of aviation PEM fuel cells under reliability aspects” is investigating how fuel cells age in aircraft and what can be done to prevent this.

As part of the EU-funded “EFACA–Environmentally Friendly Aviation for all Classes of Aircraft” project, the Institute is researching particularly robust and safe PEM fuel cell systems for commercial aviation. At the heart of the project is the development of a novel cooling system that uses heat pump technology to raise the temperature of the waste heat from the fuel cells. The aim is to reduce the otherwise large surface area of heat exchangers to the ambient air, significantly reduce the drag of fuel cell-powered aircraft and ultimately make them more efficient. The project is also investigating novel gas diffusion layer structures to improve the power density and reliability of fuel cells for use in commercial aviation.

The “Urban Scooter” project focuses on an electric scooter: hybrid fuel cell drives for mopeds are investigated with the “H2-Schwalbe”. The “H2-ER – Hydrogen Escape Room” project aims to set up a new laboratory event in the form of an escape room. Topics such as hydrogen safety, operation and diagnosis of fuel cells are conveyed in a particularly vivid and playful way.

The Institute is also closely involved in the H2 Terminal joint project in the field of fuel cell systems and drives.

Institute for Particle Technology

A team led by Professor Sabrina Zellmer is contributing its research to the Salzgitter Hydrogen Campus. Here, a broad alliance of industrial and municipal partners, the Allianz für die Region, the Fraunhofer Institute for Surface Engineering and Thin Films (IST) and TU Braunschweig are conducting application-oriented research along the entire hydrogen value chain. Research topics include the evaluation of transport chains, the investigation of storage options, the production and recycling of fuel cells and the use of hydrogen technologies in factory systems.

TU Braunschweig is also part of the “German-Australian Hydrogen Innovation and Technology Incubator” (HyGATE) funding initiative, in which German and Australian research institutes are working to establish a complete supply chain for green hydrogen. TU Braunschweig is part of the Energy Research Centre of Lower Saxony (EFZN), a joint scientific centre of the universities of Braunschweig, Clausthal, Göttingen, Hanover and Oldenburg.

Institute of Jet Propulsion and Turbomachinery

Hydrogen could make sustainable flying possible in the near future. A team led by Professor Jens Friedrichs is currently working on this vision in two hydrogen projects. The “Design-space Evaluation of the air-, heat- and power management of Fuel Cells for Aviation” (DEFCA) project in the SE²A Cluster of Excellence for Sustainable and Energy-Efficient Aviation is investigating the air supply to the fuel cell stack of a medium-haul aircraft. In order for fuel cells to be used efficiently at high altitudes, they require an air management system that continuously supplies the fuel cell stack with compressed and conditioned air.

For the use of fuel cells in aviation, it is also important that the ambient air is preconditioned to an optimum pressure and temperature level. In some cases, a turbine in the fuel cell exhaust is used for this purpose. However, condensation phenomena occur in the turbine, which is being investigated by the DFG project “Condensation phenomena in fuel cell systems for aviation ” (KONBREFF). In addition, the research group “Alternative Aviation Propulsion”, led by Assistant Professor Federica Ferraro, is working to develop new alternatives to fossil fuels, including hydrogen, to make propulsion systems for aviation greener and more environmentally friendly.

Institute of Aircraft Design and Lightweight Structures

The Institute is working on a crash energy absorption concept as part of the major EU Clean Aviation project “Fuselage, Rear Fuselage and Empennage with Cabin and Cargo Architecture Solution validation and Technologies for H2 integration” (FASTER-H2), led by Airbus. The aim is to ensure the safety of a future aircraft with a liquid hydrogen tank in the event of a survivable crash landing and to ensure that the tank remains undamaged.

In the SE²A Cluster of Excellence project “B5.2 – Application of physics-based finite-element tools in stiffness tailored structures for cryogenic hydrogen storage for improved mechanical and thermo-mechanical response”, the Institute is investigating the thermo-mechanical behaviour of fibre composite liquid hydrogen tanks in collaboration with TU Delft (NL). The institute also has a junior research group within SE²A, dedicated to future aircraft configurations with advanced fuselage structures and propulsion technologies. For example, the group is designing configurations with hydrogen combustion or hydrogen fuel cell propulsion systems that could minimise overall emissions.

Institute for Thermodynamics

Since 2007, the institute has been working on PEM fuel cells, primarily for use in land-based vehicles and in aviation.

One focus is the modelling of the fuel cell stack and the fuel cell system. Using these models, the Institute analyses and optimises fuel cell stacks and their operation for megawatt-class propulsion systems for passenger aircraft, for example in the research project “SKAiB – Scalable fuel cell systems for electric drives” together with Airbus, Aerostack and other partners. In this project and in the “FC-Truck” project, the Institute is researching innovative thermal and water management concepts for fuel cell systems in aircraft and trucks to make them smaller, lighter and more efficient. The employees are also working on water management in fuel cell systems as part of the KMU-innovativ AUTO-GEN project and the EU Clean Aviation project “Fuel Cell Propulsion System for Aircraft Megawatt Engines” (FAME).

At THEWA, the institute is particularly concerned with the model-based analysis and optimisation of hydrogen refuelling processes. A particular focus is on the pre-cooling of hydrogen, which is often required prior to refuelling. To this end, the colleagues carry out experimental and simulation-based analyses.

Initiated by the aircraft industry, several cryogenic hydrogen projects have been carried out at the Institute in recent years. A decentralised hydrogen liquefaction plant for small quantities of liquid hydrogen (LH2) is currently being designed and commissioned on the Salzgitter hydrogen campus (DEWAS project). In the future, the plant will also supply institutes of TU Braunschweig with LH2 for research purposes.

Cryostat system of the DEWAS hydrogen liquefier. Photo credit: Nicholas Lemke/Institute for Thermodynamics

As part of the SE2A project “Cryogenic exergy utilisation systems” (CEUS), the Institute is carrying out fundamental research into the exergy utilisation of liquid hydrogen in future liquid hydrogen-based aircraft. Processes for the exergy utilisation of hydrogen are being developed for different aircraft, which convert the exergy into usable energy in such a way that the hydrogen requirements of these aircraft can be reduced as much as possible.

Institute of Machine Tools and Production Technology

As part of the joint H2 Terminal project, the Institute is researching the simulation of dynamic operating strategies for electrolysers, the environmental assessment of hydrogen production, storage, distribution and use, and the application of hydrogen technologies for the decarbonisation of industrial production systems. The institute is also involved in the projects and organisation of the Salzgitter Hydrogen Campus. As part of H2Giga, the joint project Install AWE is developing the large-scale production of electrolysers for alkaline water electrolysis. The project focuses on the industrialisation of alkaline water electrolysis (AWE), which is already of high market relevance, especially for large-scale industrial applications. As part of the H2NRY collaborative project, the Institute is investigating how the use of innovative automation solutions can reduce production times for the assembly of alkaline electrolysis cells.

In the “essPresso” joint project, the Institute is working on a manufacturing process for graphite bipolar plates for PEM fuel cells. Different material formulations, tooling, handling and process solutions are being investigated. The aim is not only to increase production rates, but also to reduce energy consumption and overall manufacturing costs.

The third funding phase of the Kopernikus project “SynErgie” is investigating how industry can contribute to the energy transition: How can useful energy demand (including heat) be made energy flexible and what are the implications for the resilience of production systems? Hydrogen technologies such as electrolysers, fuel cells and direct combustion will be analysed for their suitability for energy flexibility.

Institute of Automotive Management and Industrial Production

In the joint project “HyNEAT – Hydrogen Supply Networks’ Evolution for Air Transport”, the Institute, together with other scientific institutions, is investigating concepts for the global hydrogen supply infrastructure for hydrogen-powered aircraft. The Institute’s work focuses on modelling aircraft networks and analysing the system dynamics of hydrogen demand in aviation.

The Institute is also involved in the THEWA innovation laboratory, where it uses models to assess the economic viability of individual hydrogen refuelling systems and contributes to network planning of refuelling systems.

In addition, scientists at the Institute are investigating whether and to what extent the use of hydrogen in steel production can be economically viable in the project “HyWiS – Economic evaluation of the use of hydrogen in steel production “.

Institute of Energy and Process Systems Engineering

Project logo of the DiTo-H2 project: It illustrates the planned steps from the material and its properties (magnifying glass) to the digital simulation (slider; monitor) to the performance and cost evaluation (paper; calculator). Image credit: Jana Mrowetz and Nicolas Schlüter, Institute of Energy and Process Systems Engineering/TU Braunschweig

In the project “Digital toolbox for hydrogen production: Bridging material innovations, electrolyser architecture and grid scale impact” (DiTo- H2), a digital toolbox for hydrogen production is being developed in collaboration with the University of Strathclyde (UK). In the context of the InnoEly innovation lab, the institute is developing a machine learning-based model to describe electrolysis stacks. For the planned H2 Terminal, the institute is developing and validating a model that describes the performance of electrolysers in dynamic operation.

elenia Institute for High Voltage Technology and Power Systems

elenia is also involved in the H2 Terminal with its research. elenia’s role is to coordinate sub-project II of the scientific support for the establishment of the Hydrogen Competence Centre by the seven university institutes and TU Braunschweig’s Division 3. In addition, elenia is responsible for the network and system integration of the Hydrogen Competence Centre.

Institute for Engineering Design

The institute supports hydrogen research at TU Braunschweig primarily in the area of methodology by creating descriptive models for hydrogen refuelling systems using the model-based systems engineering approach and by developing a tool network that combines the descriptive model with analytical models. This enables the optimisation of hydrogen refuelling station concepts.

(Status: May 2024)