No stress for mussels and barnacles A visit to the construction site of the saltwater wave current flume

The massive hole in the laboratory of the Leichtweiß Institute for Hydraulic Engineering and Water Resources (LWI) has disappeared. Since our last visit to the construction site of the large-scale saltwater research facility, a lot has happened. Among other things, the underwater windows were recently installed. A look at the construction site.

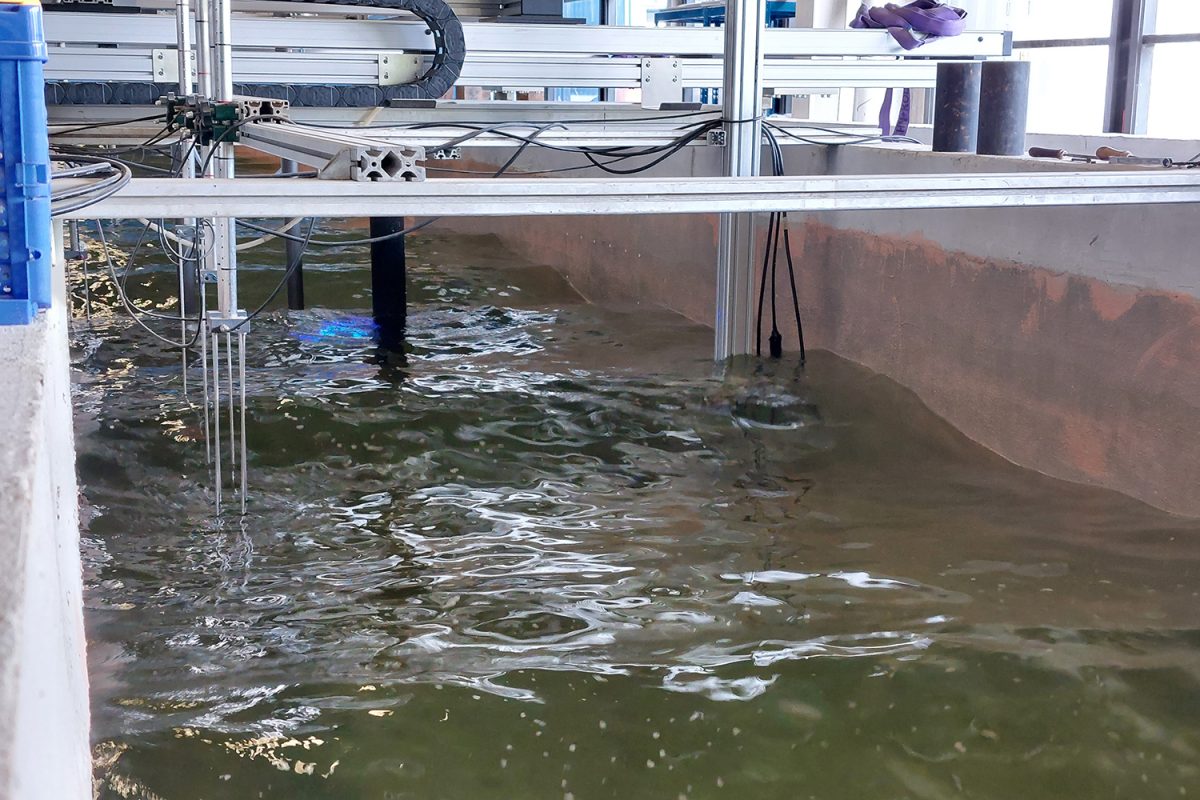

The saltwater wave current flume is a total of 30 metres long, three metres wide and 2.5 metres deep. Photo credit: Heiko Jacobs/TU Braunschweig

The windows are still covered with protective film. In future, the scientists will be able to look into the channel from the side, as if into an aquarium, and observe and document their experiments. The 6.4 metre by 2.5 metre area is divided into four windows made of one hundred millimetre thick acrylic glass.

Slowly, the dimensions of the wave and current channel are becoming visible: the structure is 30 metres long, three metres wide and 2.5 metres deep. Together with the water treatment system, the facility takes up about a quarter of the 5,600 square metre laboratory. Here, the researchers in the “EnviSim4Mare” project funded by the Federal Ministry of Economics and Technology want to investigate how the growth of mussels, algae and other sea creatures influences the load-bearing capacity of offshore wind turbines and other maritime structures.

546 metres of water pipes

A sophisticated pipe system with various circuits is necessary for the operation of the canal. A total of around 546 metres of water pipes will be laid. Additionally, there are further pipelines for heat and cold distribution. After all, water is of course the main element in the canal—and not in short supply: the total volume is equivalent to about 1,000 commercially available sea aquariums of 350 litres each. 350 cubic metres of seawater are produced by mixing a highly concentrated brine with fresh water in the water treatment plant. The seawater then offers conditions similar to the salt water in the North and Baltic Seas.

The only thing missing are the waves. The two identical wave machines, each with a blade of 2.5 by three metres, have already been installed to ensure the most uniform wave pattern possible later on. The machines can generate waves up to 80 centimetres high. In addition, there are four pumps for generating the current.

Filtering water in three stages

Why are there three large blue containers next to the canal? “That’s the three-stage filtration system with sand filter, ozone treatment and biological trickle filter,” explains Dr.-Ing. Constantin Schweiger, a research associate in the Department of Hydromechanics, Coastal and Ocean Engineering at the LWI. The trickle filter can clean up to 350 cubic metres of salt water per hour. It is designed so that the entire volume of water passes through the filter once an hour. “For keeping mussels and other marine organisms, it is important to purify and temper the water and add nutrients in a targeted manner,” says senior engineer Dr.-Ing. David Schürenkamp. “The marine organisms used should experience as little stress as possible so that they can be studied under realistic conditions.”

In order for the marine organisms—i.e. mussels, barnacles and algae from the North Sea—to get used to the conditions outside their usual marine environment, they are first placed in a holding tank, which is also not too small with a volume of 14.4 cubic metres – about 40 standard household seawater aquariums. The organisms are still growing on test bodies in the North Sea, which were deployed at suitable offshore locations around Helgoland and the Nordergründe wind farm. Before the first experiments begin, they will be transported to Braunschweig.

Protection for the “marine climate”

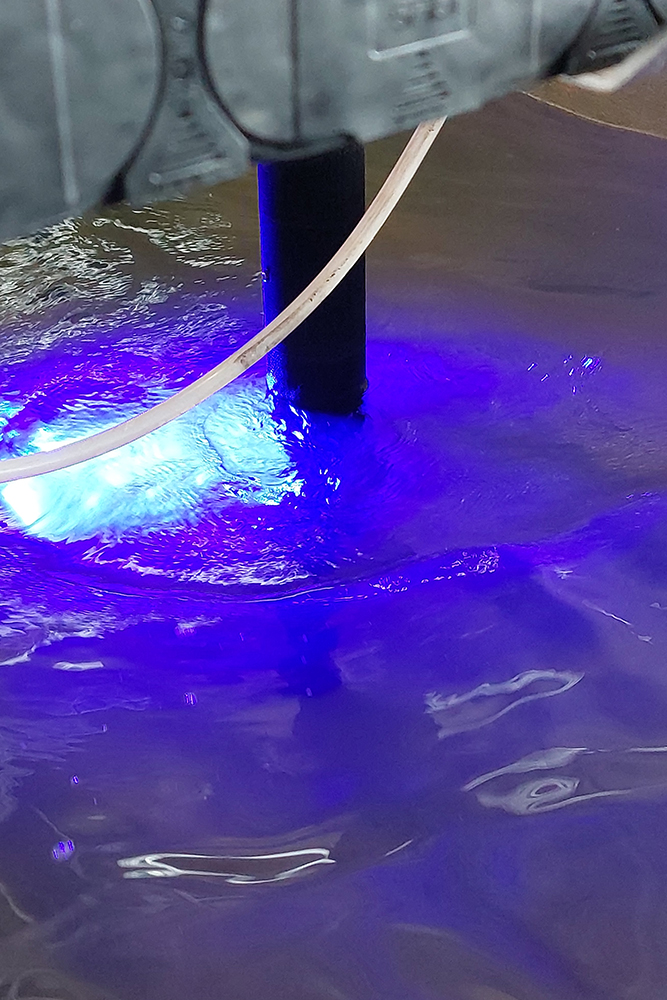

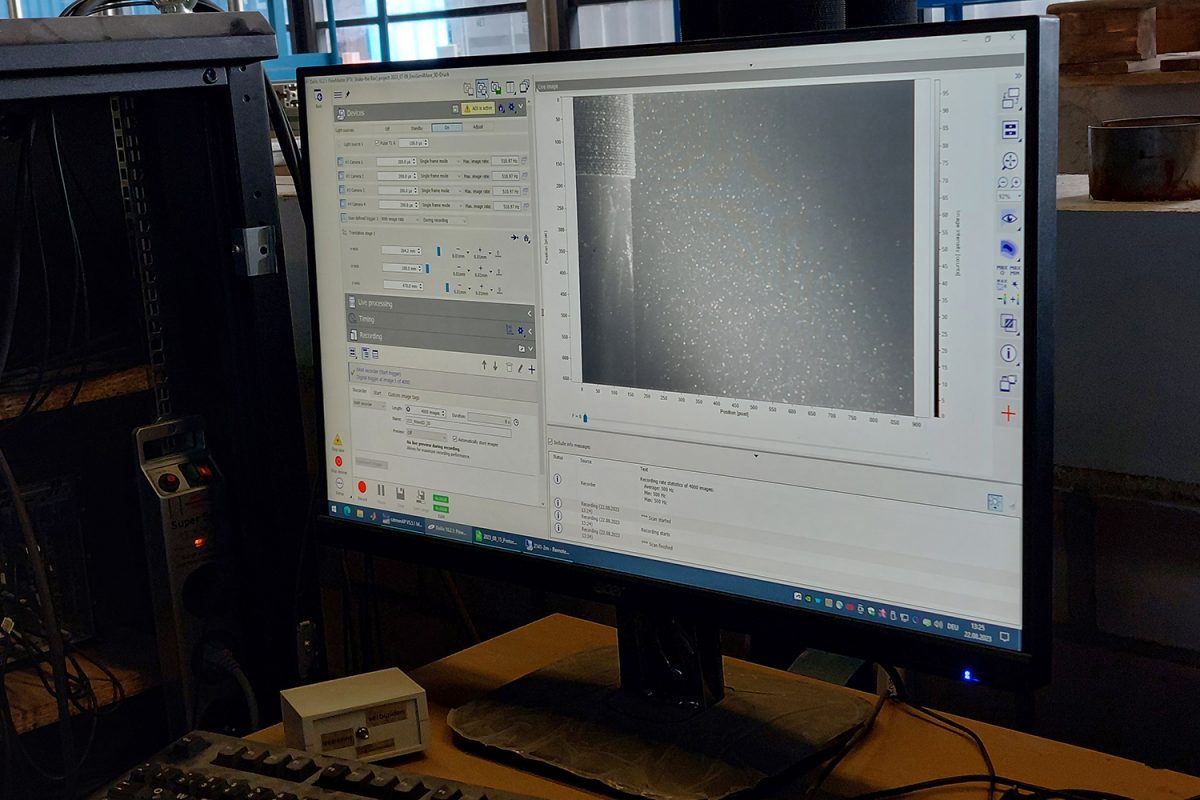

In the meantime, in the wave channel next to the construction site, tests are continuing with the so-called Shake-The-Box 4D-PTV system, which measures the flow around structures. Instead of piles with living organisms, 3D-printed cylinders have been used so far, which reproduce the structure of adhering mussels and barnacles. The scientists can use the high-tech device to study how the force acting on the piles changes depending on the vegetation and later draw conclusions about the possible operating time of offshore wind turbines. Among other things, marine vegetation increases the surface area of structures in the sea and thus also the force effect of waves and currents on the structure. The aim is to be able to extend the service life of existing offshore wind turbines through a more accurate reassessment of the experienced loads. In addition, more economical dimensioning of offshore support and foundation structures should be made possible by the research results.

When the saltwater wave current flume is completed at the end of this year, the 4D PTV system will also be transferred to the new flume and the first tests can start—with real mussels and barnacles. Not much will be visible of the canal itself. It will be given an enclosure that can be closed off with sliding elements for the experiments. The shell forms a protection so that the “marine climate” remains in the canal and is not disturbed from the outside.