Picture of the Month: Layer by layer to a steel structure From the Institute of Joining and Welding

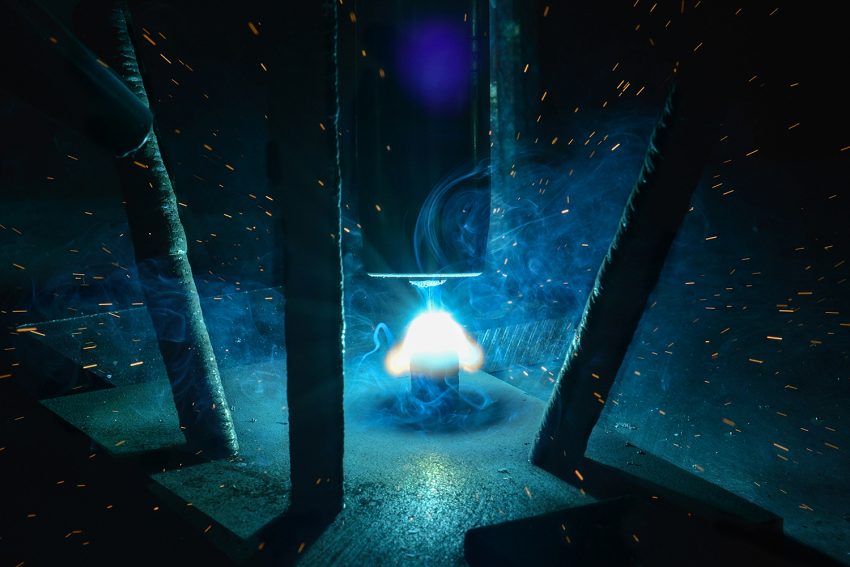

The idea: manufacturing connecting elements of complex steel beam structures, such as those used in the Allianz Arena in Munich, more cost-effectively and flexibly in the future using additive manufacturing technologies. The Collaborative Research Centre TRR 277 “Additive Manufacturing in Construction (AMC)” is investigating how digital manufacturing technologies can be introduced into the construction industry. One possibility for manufacturing steel components is the process of wire-based additive manufacturing using arc welding. The Institute of Joining and Welding is investigating the effects of this process, which takes place at extremely high temperatures, on the properties of the complex components produced in this way in a sub-project. Our picture of the month for December shows an over 8,000 degree hot, blue shimmering plasma column of arc welding during a material application in the production of a rod connection.

A snapshot during the production of a rod structure. Shimmering blue the plasma column of arc welding at over 8,000 degrees. Photo credit: Markus Köhler/Institute of Joining and Welding

There are already a large number of additive manufacturing processes. Due to high deposition rates of about five kilograms in one hour with simultaneously high material utilisation, wire-based additive manufacturing by means of arc welding (Wire Arc Additive Manufacturing – WAAM) represents a promising alternative to conventional manufacturing processes. In this process, the wire-shaped starting material is melted via an arc welding process and applied in layers in a geometrically defined manner through a relative movement between the workpiece and the material feed.

Individual Anchoring Structures

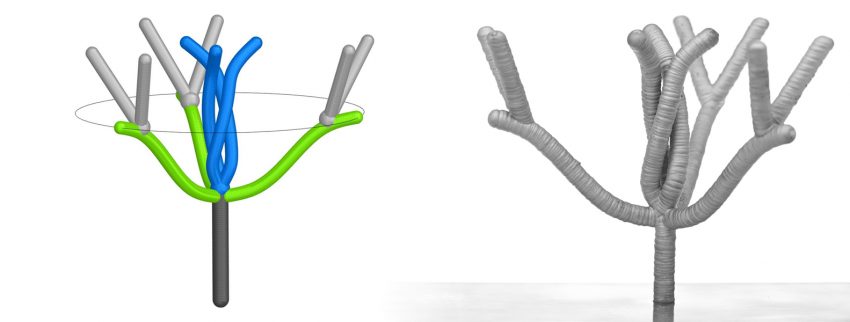

Virtual and physical model of an exemplary anchoring structure. Picture credit: Institute of Joining and Welding/TU Braunschweig

In addition to geometrically complex solid bodies, bar-shaped free-form structures can also be created by specifically adjusting the welding time and material input. For this purpose, the arc is ignited for a defined time, material is fed in, and after the arc has extinguished, the welding torch is moved in the direction of assembly and the process starts again from the beginning.

Digital Models

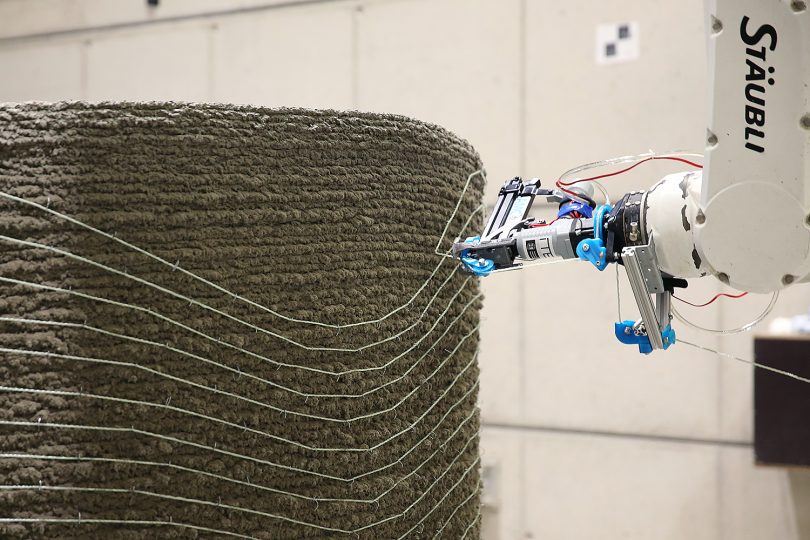

The arc welding process is not new, but what is new is the use of digital models. With the help of computer programmes, the nodes are designed and then the path planning data is passed on to the welding robot control system on the basis of the CAD model. The task of the sub-project is to find out what effects the manufacturing process of layer-by-layer application of molten steel at high temperatures has on the properties and thus the quality of the component.

Background

The research of the Institute of Joining and Welding presented in this article is carried out as part of the project “Wire Arc Additive Manufacturing (WAAM) of Complex and Refined Steel Components (A07)”. The project is part of the Collaborative Research Centre “Additive Manufacturing in Construction – The Challenge of Large Scale” – project number 414265976 – TRR 277 of TU Braunschweig and TU Munich.