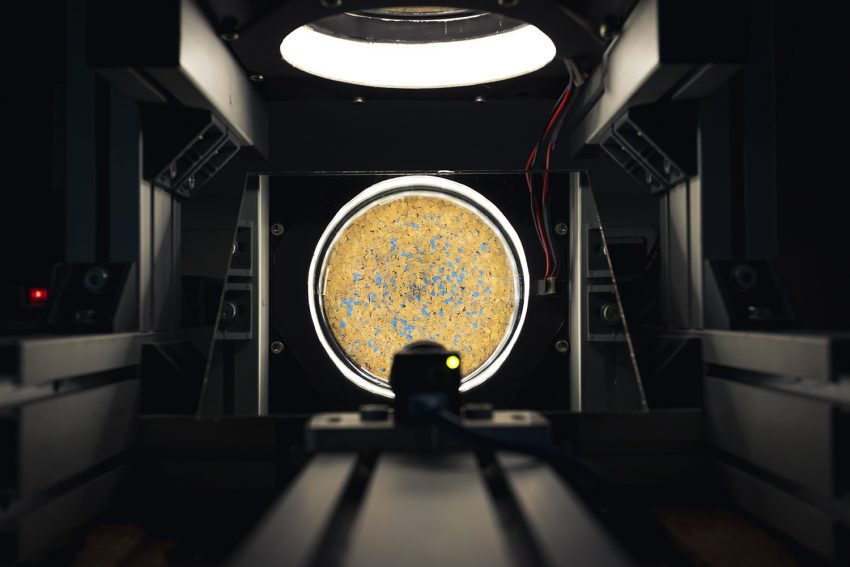

Picture of the month: From the inside of friction Submitted by Professor Georg-Peter Ostermeyer

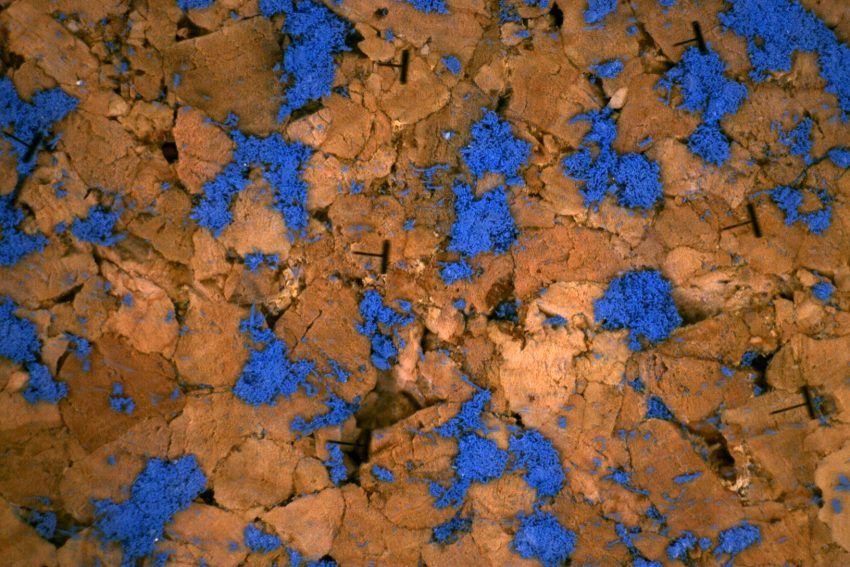

Without friction, nothing works in our everyday life. Sometimes friction is vital, as in vehicle braking, sometimes it is undesirable, as when the bicycle rolls out and we have to pedal again. Such frictional forces still cannot be accurately calculated or predicted. This gap in our knowledge has lasted for an astonishingly long time. Research into the prediction of friction has been going on since Leonardo da Vinci. Professor Georg-Peter Ostermeyer of the Institute of Dynamics and Vibrations would like to shed more light on the darkness of the phenomena of friction with an innovative machine, which can be seen in the picture of the month. His machine, which was completely new for basic research, makes it possible to see in situ inside the frictional contact between two bodies. The frictional interface reveals surprisingly complex dynamics of wave motion and wear particle flow. Cork particles moving in an almost dancing fashion are exemplified in the image. The machine makes it possible to observe the complex self-organization effects and thus contribute significantly to the clarification of different phenomena of friction, wear and the origin of friction dust emissions.

Among other things, the Wear Debris Investigator machine designed by Professor Ostermeyer is intended to provide answers to questions about the frictional force of brakes. Photo credit: Max Fuhrmann

Although friction is ubiquitous, friction is still not understood causally. We have been using friction and its effects since time immemorial. In the Stone Age, our ancestors made fire with wood rubbed against each other. Even today, friction is used to make fire. The ancient Egyptians also moved large stone blocks over long distances using roller beams that were probably oiled. We also still use these techniques today to minimize drag forces. Friction is sometimes desirable and sometimes not. On the one hand, there is no walking, running or rolling without friction, as you can easily see on a frozen lake. Here, only very small steps or accelerations are possible. But on the other hand, friction is also responsible for an incredible amount of energy destruction in our world, because the functionality of many processes and machines contains friction as an unwanted and unavoidable by-product, which has to be served energetically.

Artificial wear particles between soft cork and hard glass in Wear Debris Investigator. Photo credit: Kristina Rottig/TU Braunschweig

In the mid-15th century, Leonardo da Vinci was probably the first scientist to set out basic properties of friction in experimental sketches. Although a great many experiments, explanations and results have been generated since then, the very simple Coulomb’s law of friction for the elementary states of adhesion and sliding is still often used in simulation and system description today. This law for dry friction gives quite good results when one has approximate point contacts and friction does not dominate the system events energetically or phenomenologically.

Better predictions of friction needed

Mathematical and computational developments in recent decades have enabled system dynamics to develop increasingly accurate mathematical representations of machines and processes, known as digital twins. The aim is to use these virtual functional copies of real systems as cost-effective substitutes for real processes that pose a risk to health or for expensive hardware developments in early development phases. However, this is only possible if the model’s behavior is sufficiently close to reality in terms of the questions it is asked.

This already works fascinatingly well. Apart from the mathematical-informatic side, the background is that all elementary especially mechanical forces except friction are well understood. These can be measured very well. They are used, usually combined with each other and coupled with non-mechanical quantities, to provide increasingly accurate system predictions in many areas of our daily lives. System dynamics has therefore taken off on an unprecedented triumphant march, especially in the last few decades. Among other things, these elementary forces enable simulation kits that allow even non-experts to build digital twins.

However, the complexity of nonlinear dynamics such as self-organization, chaos and turbulence, as well as the nature of the last unknown elementary force of mechanics, friction, are the limits of this approach.

Still no complete scientific explanation of the friction force in brakes

This is particularly evident in tribological high-load contacts such as brakes. Brakes consist of discs or drums against which pads are pressed. The linings themselves consist of up to 20 different ingredients, usually bound in resin. The friction pairings must generate high frictional forces at all times, but at the same time should have a long service life. The development of the linings is a well-kept secret of the companies. It is defined almost exclusively by trial and error. A causal scientific explanation of the friction force from the ingredients and the resulting mechanical, thermal and chemical reactions does not even exist to this day. Why the frictional force differs at different times under otherwise exactly the same conditions is only now beginning to be understood. The wear dust in the friction boundary layer forms temporary additional friction surfaces, which essentially store the short-term load history of the brake. Another issue in focus today is the emitted brake wear dust, which shapes a vehicle’s emissions signature as engine emissions continue to decline. Together with some tire wear, they form long-lived and sometimes respirable pollutants in the air.

Aiming to reduce emissions

How can brake emissions in the city be reduced through meaningful braking actions and traffic control measures to more effectively protect residents, for example? How must the material structure of brake pads be changed so that emissions are less harmful to health?

These questions are completely open. The machine in the picture of the month is intended to provide initial answers.