Superconducting Sensors for the Fastest Computer Chips in the World Interview with a large-scale instrument: The Terahertz Microscope

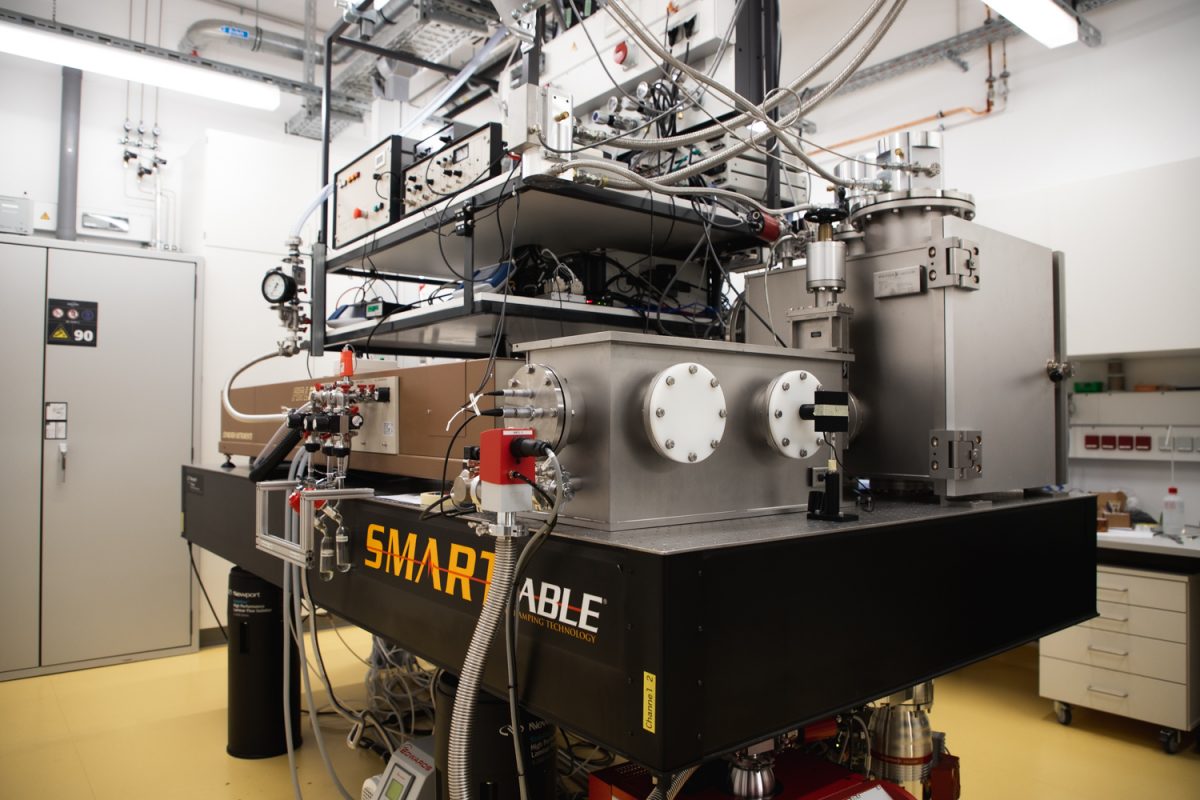

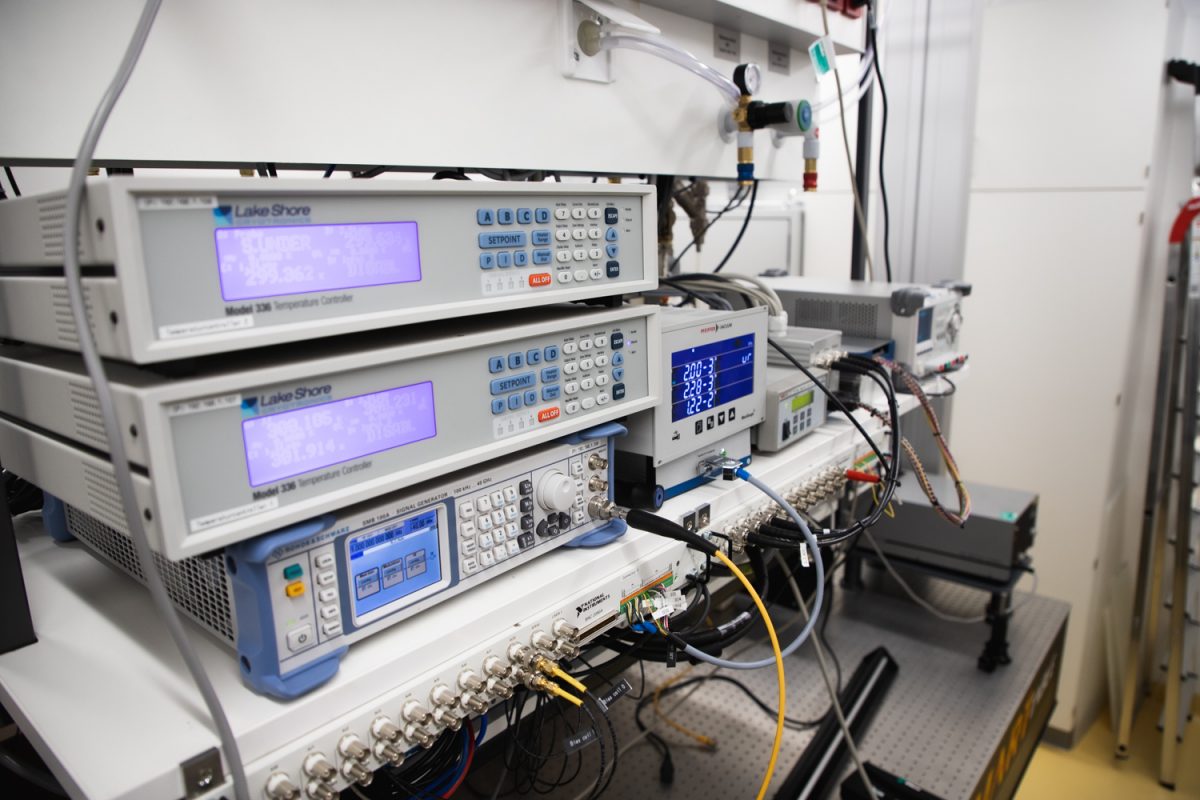

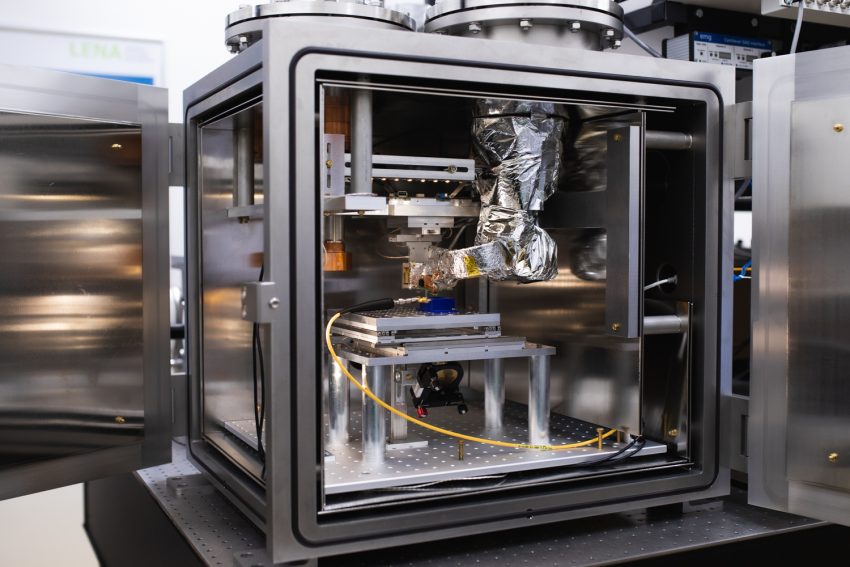

From the outside it is a nondescript door at the Laboratory for Emerging Nanometrology, the LENA, of Technische Universität Braunschweig. Inside, a room awaits with technology piled up to the ceiling, which is over four meters high. Shiny silver equipment, countless tubes and cables, a humming and blinking. So this is a Terahertz Microscope. I wonder what it does all day long?

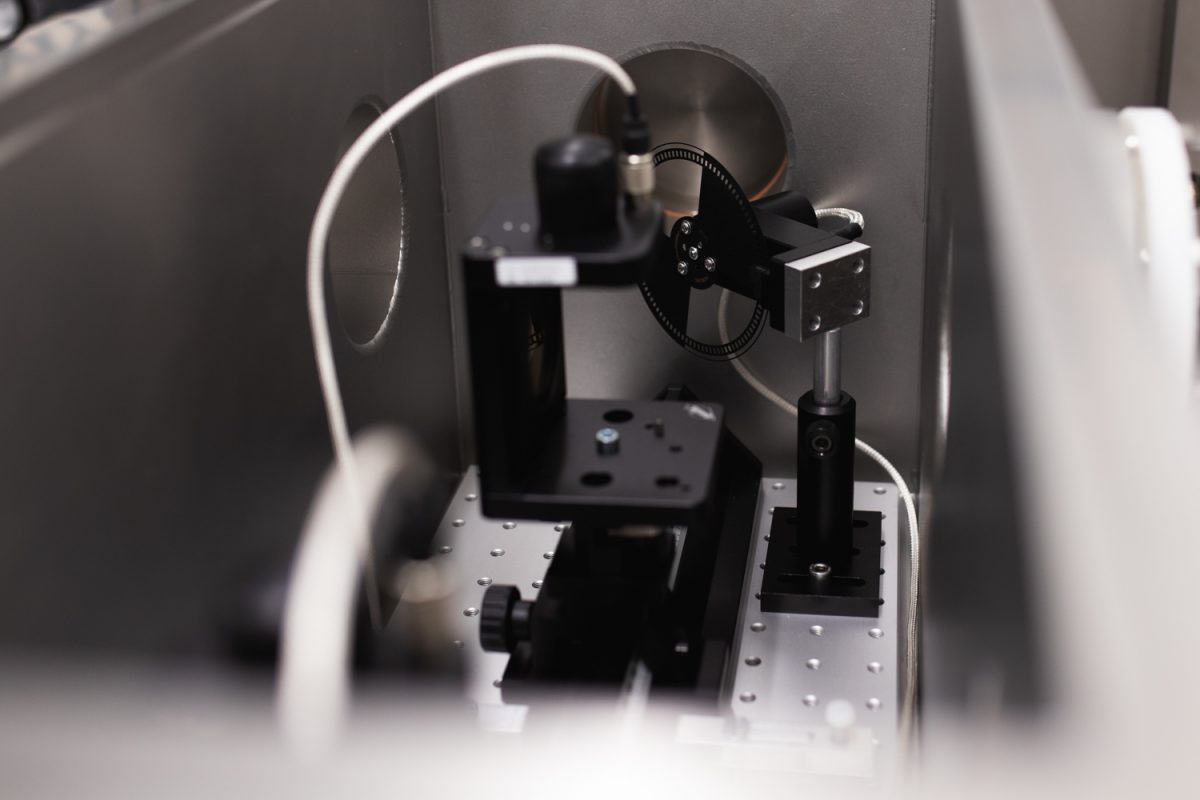

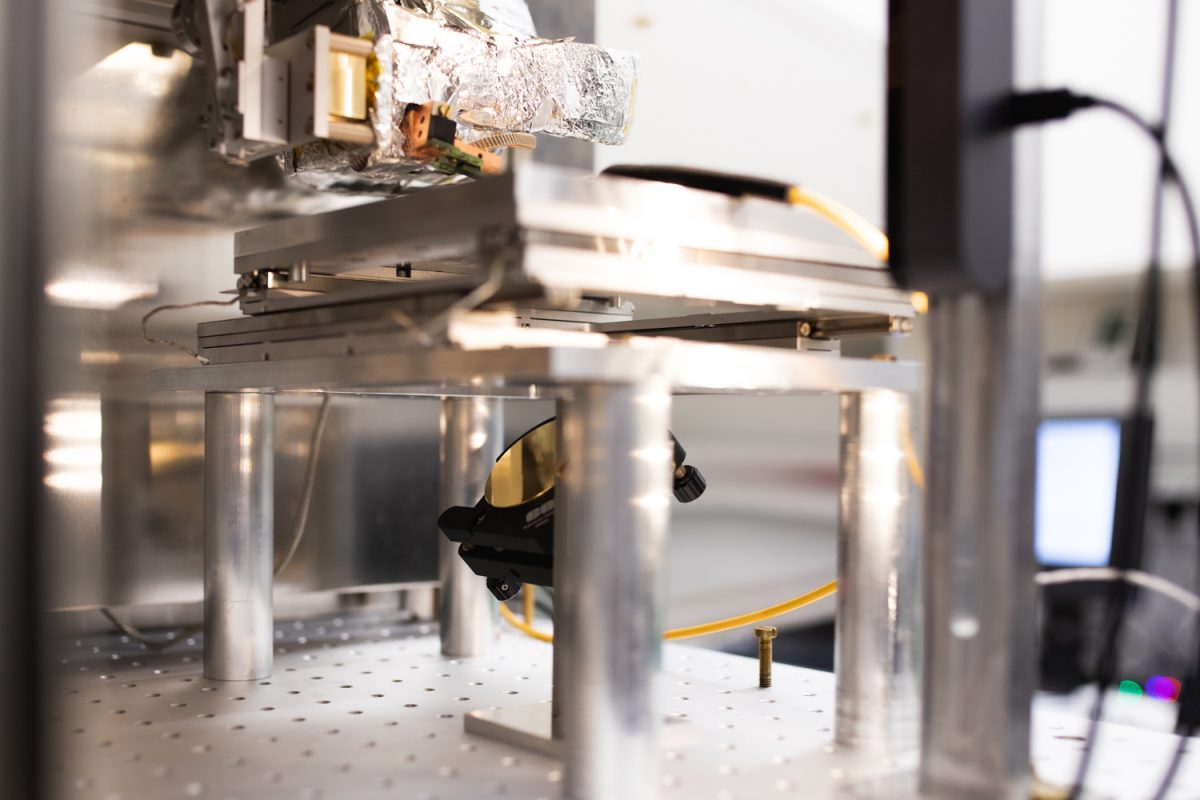

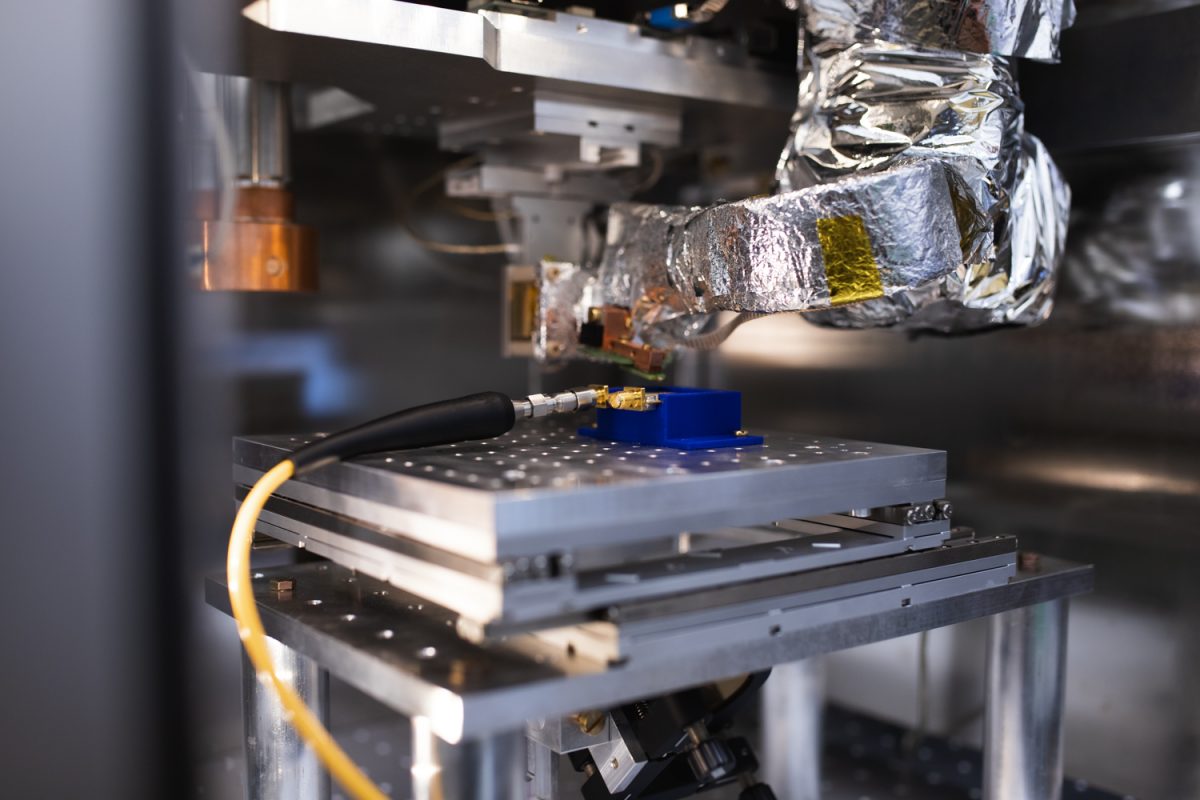

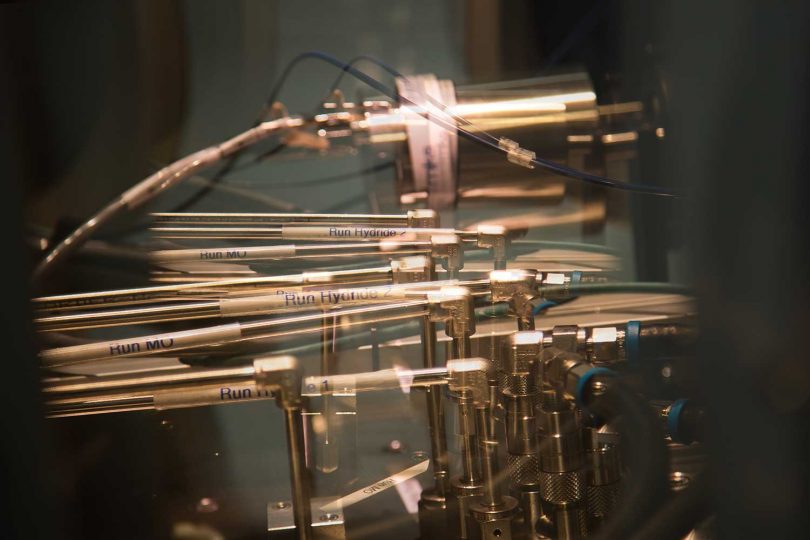

Terahertz Microscope: “In the picture you are looking into my vacuum chamber, i.e. where I am measuring. Picture credits: Max Fuhrmann/TU Braunschweig

Hello, Terahertz Microscope. How would you describe yourself and what do you do anyway?

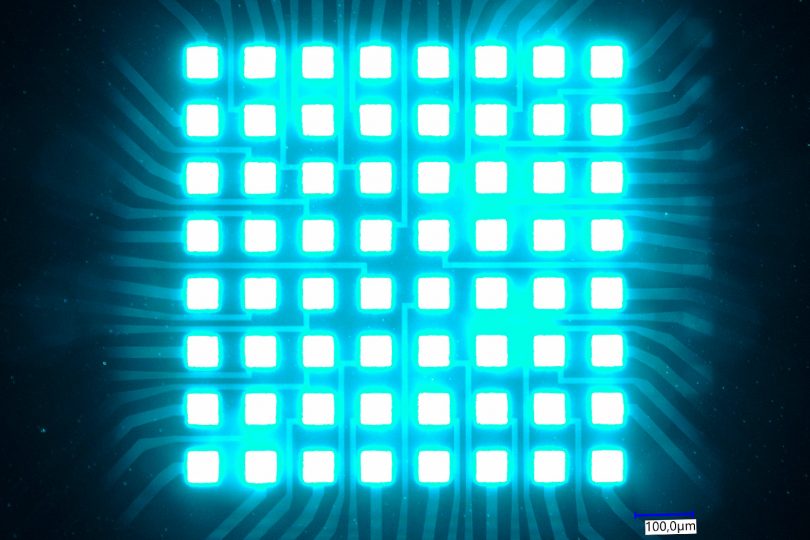

Nobody has told you that yet? I am a worldwide unique specimen, handmade by my scientists. When someone puts a measuring object, for example a very fast computer chip, into my vacuum chamber, I use my superconducting sensor to travel to my target within a few micrometers. And there I detect the radiated power of high-frequency electromagnetic radiation, up to terahertz frequencies. If something does not generate its own power, I also have my own terahertz sources. For example, I use a laser to shoot at grid structures that specifically diffract the radiation. In doing so, I detect how radiation and object interact with each other. Afterwards I even generate a three-dimensional image of how the radiation power is distributed. But even if I prefer to measure electromagnetic radiation: I can also detect static magnetic fields and even temperature distributions.

Are you unique? Why were you created?

To do research on terahertz radiation. It ranges from about 300 gigahertz to 10 terahertz. This puts it above microwaves, which is what radar, WLAN and mobile phones use, and at the same time below infrared radiation. For a long time, it was hardly possible to generate such radiation in this range, let alone measure it precisely. Accordingly, terahertz radiation did not make it into our everyday lives. It is called the “terahertz gap”. I am one of those who want to close this gap.

Much of what I am I owe to my big brother at the Institute of Electrical Measurement Science and Fundamental Electrical Engineering (EMG): He showed as a so-called “proof of pinciple” that terahertz microscopy works. All his experience then flowed into my development.

What exactly are you doing to close this gap?

I make terahertz radiation visible. With my measurement data, new technologies can be explored that use terahertz radiation for a variety of purposes. For example, I am working together with the Physikalisch-Technische Bundesanstalt (PTB) on a project on the unit of voltage: volts. The PTB is setting up experiments that realise units such as seconds, kilograms or even volts with particular accuracy. For the voltage, PTB uses circuits made of the superconducting material niobium – cooled with helium to -269 degrees Celsius and irradiated with microwaves. Here the researchers use quantum effects for a relative measurement uncertainty of less than a ten billionth. In other words, at 10 volts with an accuracy of one nanovolt. This constant voltage is used to calibrate voltage measuring instruments, for example.

Here I have the high-temperature superconductor yttrium barium copper oxide in my back pocket. Quantum physics helps here as well to create ultra-precise voltage. But for this superconductor, cooling to -196 degrees Celsius with liquid nitrogen is sufficient. Compared to helium, this is child’s play. In addition, yttrium barium copper oxide can be irradiated with terahertz radiation instead of microwaves to generate higher voltages. To do this, however, the radiation must be equally strong at all points of the superconducting circuit and this is where I come in.

I can control my sensor to an accuracy of about 10 nanometers (about 100 atomic diameters). This way I can find out precisely how much terahertz radiation hits where. Thus we can optimize the voltage standard and, in the long term, get it into a handy device that can also be used by industry for calibrations. With this perspective, by the way, I am part of the QuantumFrontiers Cluster of Excellence, which aims to contribute to new quantum standards.

Many advantages for metrology, i.e. for the science of measurement. Do you also offer something for those who don’t happen to have a PhD in physics?

Have you ever been annoyed by your slow computer or faltering data transmission? So far, computer processors work with about three gigahertz – if at all. For more power, you can of course connect more processors side by side. But at the latest when you pay 4,000 Euros for 64 interconnected cores, you probably hope for an alternative. The problem is that even if someone develops a faster computer chip – its high-frequency signals remain difficult to measure. The development is correspondingly complex. I support the developers by measuring their circuits exactly. In the future, we will no longer be annoyed by computers that are too slow, but will use completely new digital technologies.

Terahertz radiation could also be used to transmit data. With the new 5G standard, 40 gigahertz are currently possible. If data is transmitted at 400 gigahertz instead, several times more data will arrive. That would be a promise of the terahertz frequency. In addition, this frequency spectrum is still virtually unused, i.e. something like a white spot in the tightly packed data transmission schedule. Even if the terahertz radiation has problems with humidity and is quickly attenuated by it: At short distances, i.e. up to 1000 meters, it is hard to beat. Many of my scientific machine colleagues in communications engineering and high-frequency engineering all over the world work on this technology with their humans, which could transmit enormous amounts of data in the future. I make my contribution by taking a close look at high-frequency radiation.

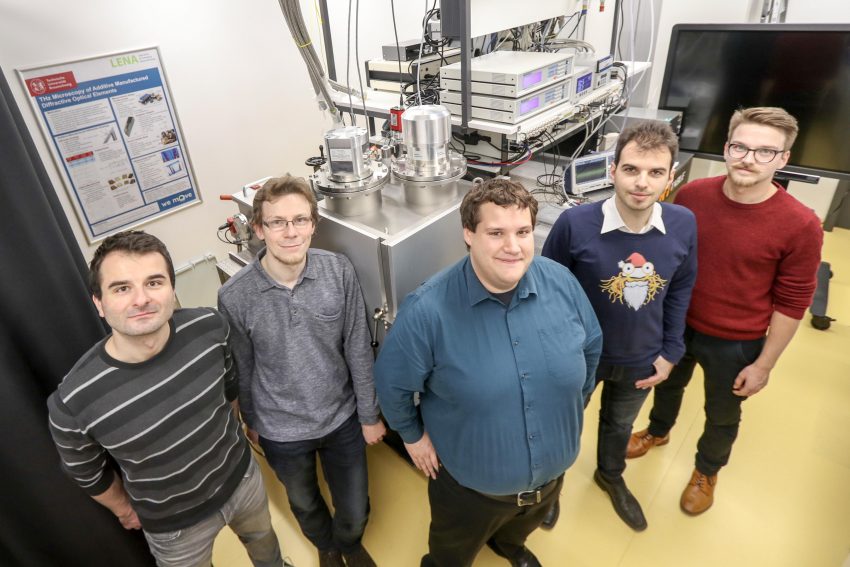

The team of the Terahertz Microscope: Picture credits: Tanja Coenen/TU Braunschweig

Admittedly this sounds quite tempting. But with all your skills – do you have any quirks?

Well, what do you mean by quirks? My humans are just merging out the last flaws in the software, but every device has them in the beginning. I’m just about to really take off. So more measuring and less intervention in my anatomy. In addition, my scientists have been working for several years to produce optical components for terahertz radiation with 3D printers. They are also printing optimizing lenses for my laser system, which I will very soon be checking for accuracy.

So you haven’t been around that long?

No, the first measurements only started this year. For three years I was assembled piece by piece at LENA and continuously inspected. The fact that I could be built at all is thanks to the prototype at the Institute for Electrical Measurement Science and the Fundamentals of Electrical Engineering (EMG). Only then was it proven that I can function.

Many thanks to Marco Tollkühn and Dr. Benedikt Hampel, the interpreters for the Terahertz Microscope. In the junior research group “Terahertz Microscopy” at the LENA Research Center, they played a major role in setting up the Terahertz Microscope.