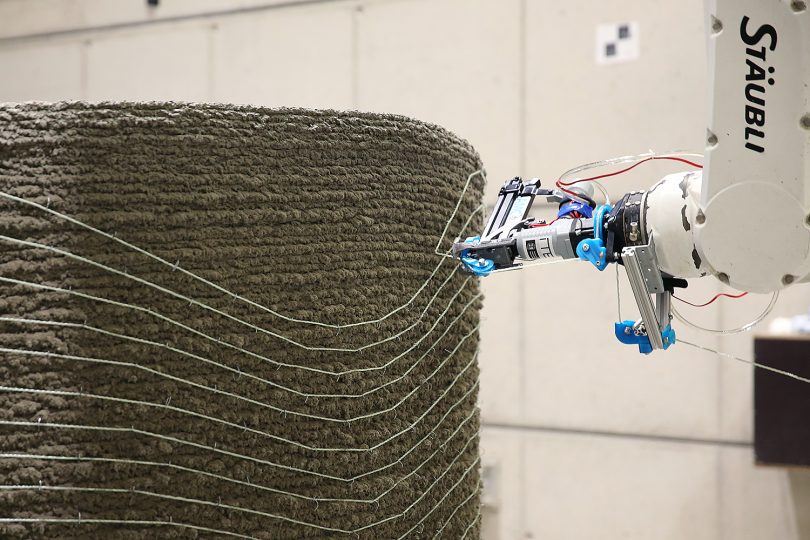

Picture of the month: Second life for concrete Institute for Particle Technology makes recycled particles suitable for 3D printing

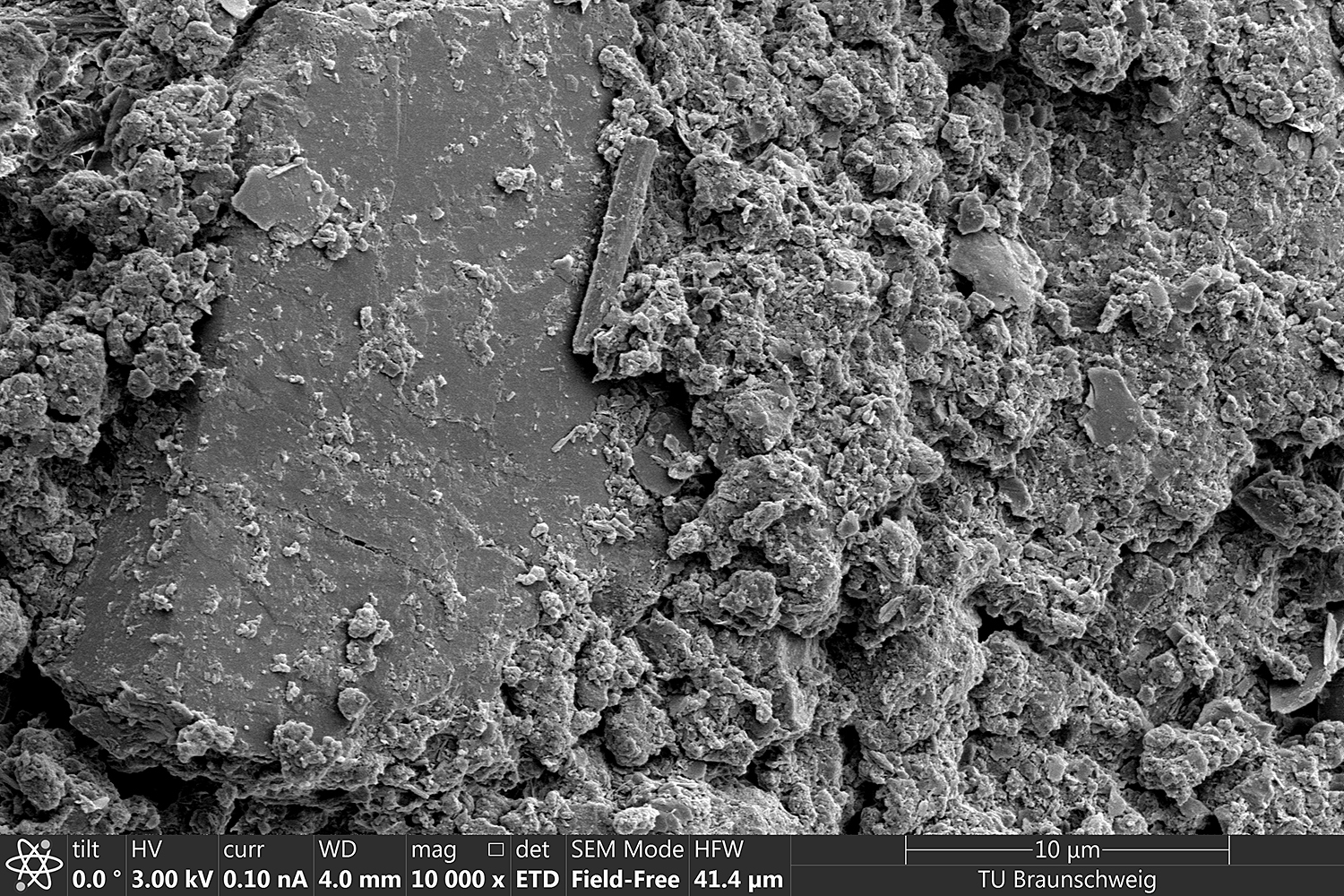

The construction industry is facing an urgent challenge to reduce resource consumption and CO2 emissions. In addition to developing new 3D printing technologies, the key question is: what materials can make construction more environmentally friendly? This is where the Institute for Particle Technology‘s research in the Collaborative Research Centre “Additive Manufacturing in Construction” (AMC) of Technische Universität Braunschweig and the Technical University of Munich comes in. The aim is to obtain recycled particles for ‘selective paste intrusion’ – a particle bed-based 3D printing technology – by recycling concrete from scrapped buildings. Our picture of the month shows a close-up of one such particle with cement residue on its surface.

A close-up of a recycled aggregate particle with cement residue on its surface at 10,000x magnification. Picture credits: Leigh Hamilton/Institute for Particle Technology

Selective paste intrusion (SPI) is a particle-bed-based additive manufacturing technology in which aggregates are spread in thin layers and bonded by cement paste. “A deeper understanding of particle technology can enhance the way we design and operate such processes, especially considering energy efficiency and sustainable solutions,” says Leigh Duncan Hamilton, Research Associate at the Institute of Particle Technology. “With that in mind, our main goal is to recover suitable recycled particles for SPI by recycling concrete from scrapped buildings.”

The road to sustainable concrete

Fresh concrete is a mixture of water, cement and aggregate particles such as sand or gravel. After hardening through the chemical reaction of water and cement, the aggregates are bound together by the resulting cement matrix. This makes recycling a complex task. There are two main mechanisms viable for crushing concrete components: the impact of a particle on a solid surface, similar to hitting a ball with a bat at very high speeds or stress by pressure/friction between two surfaces, comparable to cracking a nutshell.

The second method is preferred as it preserves aggregate particles by breaking concrete in a controlled manner. Thereafter, the particles are classified by sieving and then washed. This allows the coarse aggregates to be reused in new building materials and the remaining fine cement particles to be used as an additive in cement paste.

Understanding waste as a resource

“Construction waste is abundant, much of which is discarded due to guidelines for recycled concrete materials,” says Leigh Duncan Hamilton. “Selective paste intrusion could break new ground and create a sustainable cycle by giving discarded materials a second chance.”