Resonating scales against microplastics Wilson Ombati Nyang'au from the research training group B-IGSM

About 50 doctoral students pursue precise measurement in the “Braunschweig International Graduate School of Metrology” (B-IGSM). Wilson Ombati Nyang’au is one of 15 international students at the graduate school. Having already provided precise scales in Kenya, he determines the weight of the smallest particles in liquids at the TU Braunschweig. He tells us in an interview, how the graduate school is a place full of hospitality and support for him.

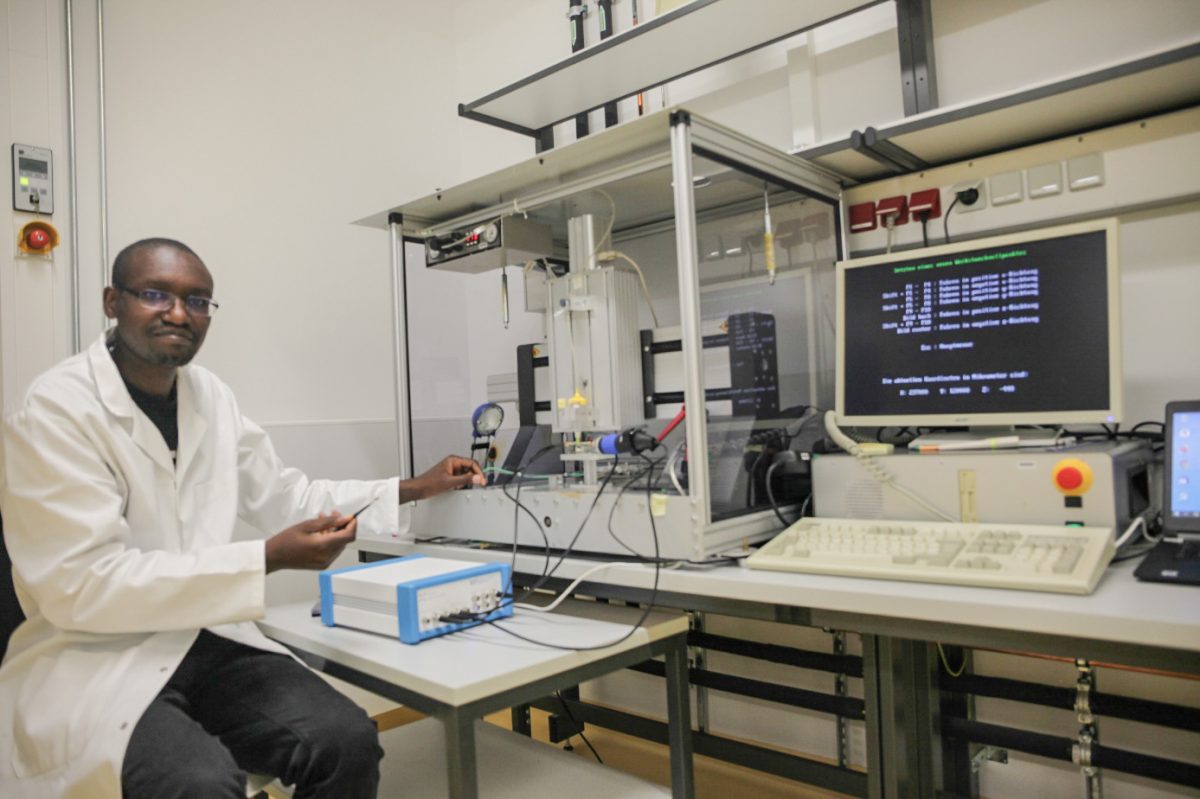

Wilson Ombati Nyang’au at his liquid dispensing and measurement setup at the Laboratory for Emerging Nanometrology (LENA). Picture Credits: Michael Fahrbach/TU Braunschweig

Who are you and what is your research topic?

I am Wilson Ombati Nyang’au, born and brought up in Kenya. I joined the Kenya Bureau of Standards (KEBS), the Kenyan National Metrology Institute, in 2011 after completing my Masters in Physics. Together with my working group, I maintained and calibrated standard weights and various weighing instruments. We ensured that they were aligned with the SI unit kilogram, the internationally defined unit for mass. My department was established thanks to the PTB, the National Metrology Institute of Germany.

Since 6th October 2017, I am doing my doctorate in the research training group B-IGSM with a scholarship of the Federal Ministry for Economic Cooperation and Development (BMZ). For my PhD thesis, I am working on a “Single Particle Mass Detector” system at the Institute of Semiconductor Technology (IHT) at TU Braunschweig. Besides TU Professor Erwin Peiner, I have a second supervisor at PTB, Dr. Harald Bosse. He heads the PTB-department of Precision Engineering and supports me with his metrological technical perspectives.

Which research question are you working on?

From the onset, my research interest was focused on a cost-effective and feasible proof of the mass of liquid-borne particles using resonating sensors. Their resonant frequency changes proportionally to attached weight, so the mass of particles in contact with the sensor can be determined precisely. Unlike airborne particles, one problem is that the liquid itself dampens the vibrations. The result is a substantial energy loss and poor detection efficiency.

To increase the efficiency, my method places a determinable number of particles in a small drop directly on the sensor. For this purpose, I developed a new generation of sensors that react more sensitively to mass. The smaller the sample, the fewer particles have to be counted. That is why I also refined the application method: Now a needle stamps the particles onto the sensor. Together with the Institute for Electrical Measurement and Fundamental Electrical Engineering (EMG), I am currently researching, how the mass and magnetic moment of particles can be measured simultaneously with the new method.

What do you find exciting about your research?

One example of liquid-borne particles is microplastics in water. The new mass sensor has great potential to counteract the increasing environmental and health risks caused by liquid-borne particles such as microplastics. Until now, measuring such particles has been extremely complex and expensive, and is therefore not adequately performed. I am developing a cost-effective, simple alternative for taking and measuring samples. This unconventional particle detection system may also flexibly be adapted and utilised to detect liquid-borne viruses such as coronavirus.

Why is your research relevant for metrology?

Microplastics are now omnipresent in our environment and threaten our health. Therefore, we need versatile sensors that can monitor our environment. The new approach for particle detection has the potential to do just that. In addition, the detection and accurate mass measurement of microscopic particles in liquids is invaluable in metrology. Pharmacology and medicine in particular depend on it. For example, the magnetic moment of particles is crucial for diagnosing und treating diseases such as tumors, or testing and dosing drugs.

What is special about participating in the research training group B-IGSM?

To me, B-IGSM has been like a home away from home. Through the weekly meetings I found an open forum to discuss my scientific results, to exchange ideas about metrology with like-minded people and to receive extensive feedback. At the meetings I also learn from the experts, the B-IGSM professors.

Furthermore, I trained a wide range of soft skills in the graduate school, for example time and stress management or scientific presentation skills. The forums of the research training group, like the metrology summer schools and scientific field excursions, also enriched my scientific skills and shaped my metrological career. At the B-IGSM I found a place of hospitality and support. It connects its students not only among each other, but also with other metrology organizations in an active network.