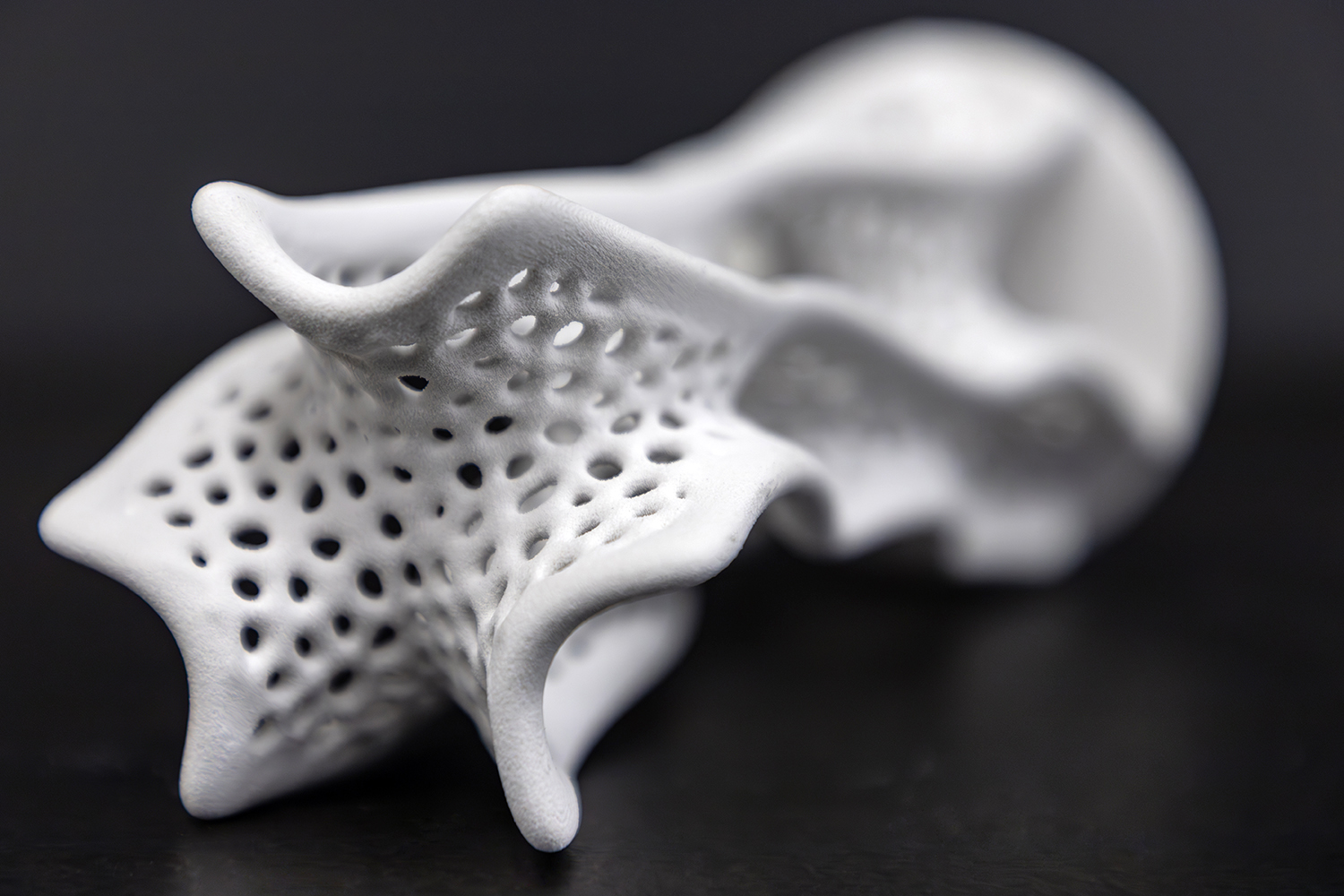

Picture of the month: The Wonderful World of Modelling Filigree structure from the plaster printer in the Model Building Workshop

Our picture of the month looks as if it has been covered in hoar-frost or fine snow. The delicate, organic shape that spirals upwards is reminiscent of structures found in nature. The filigree model was created using a plaster printer in the Model Building Workshop at Technische Universität Braunschweig. The student project is now well protected in a Plexiglas display case, along with other models from the workshop.

Filigree structure from the plaster printer in the Model Building Workshop. Picture credits: Kristina Rottig/TU Braunschweig

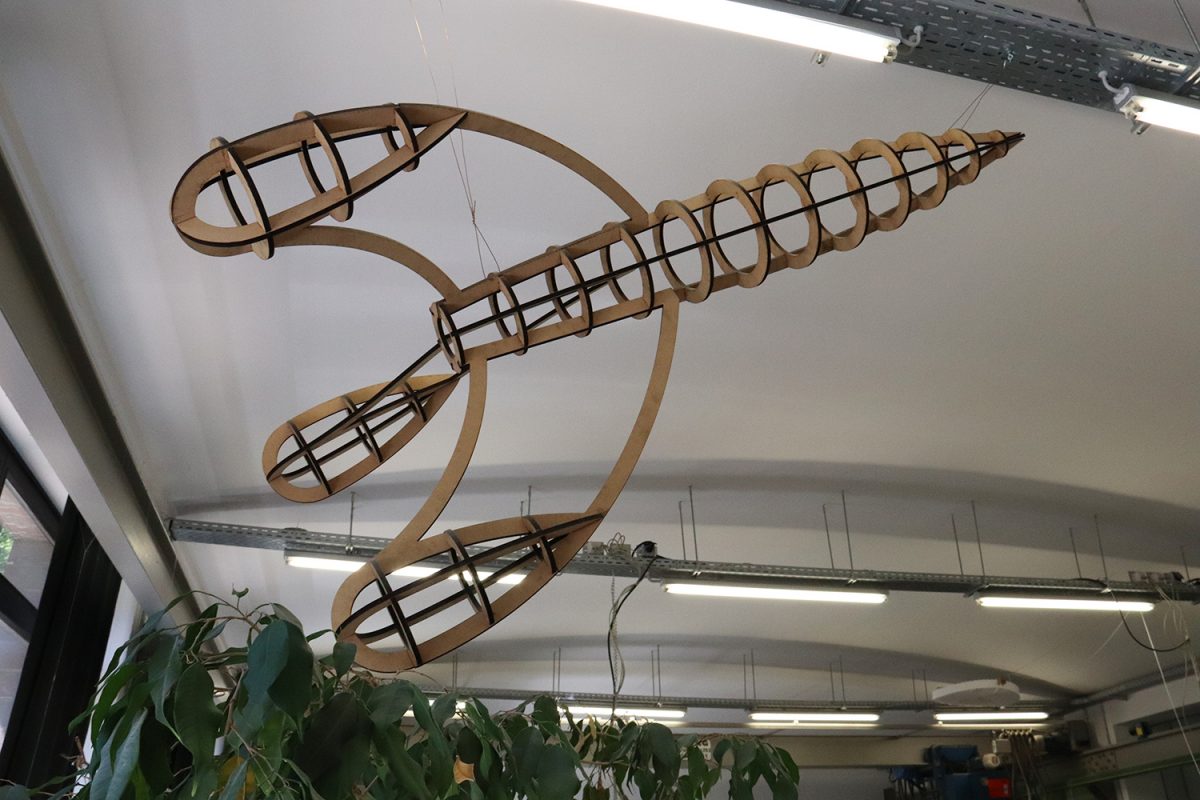

The Model Building Workshop in Pockelsstraße is spread over two floors and has around 600 square metres of excellently equipped machinery. Students can laser cut, mill, 3D print, plot, paint, drill, plane, sand and transform their computer-aided architectural designs into three-dimensional working or presentation models. The workshop, which opened in 2013, has a range of equipment that means there are virtually no limits to design.

The plaster printer, for example, allows any shape to be printed layer by layer in a powder bed without any supporting structures. The machine has since been supplemented by plastic printers. “Plaster printing is very sensitive, so the trend is now more towards plastic printing,” explains Angela Andree-Scheuner, who runs the modelling workshop together with Marko Frass.

From the saw to the 3D printer

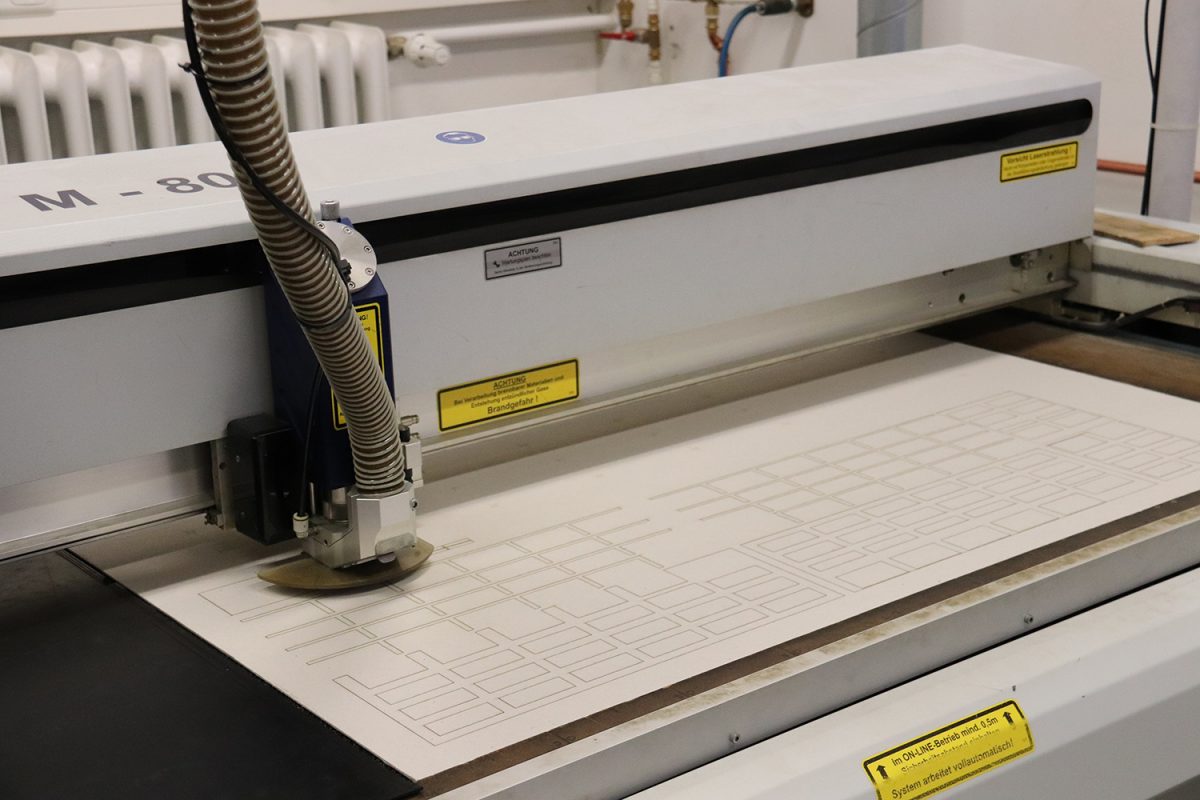

In addition to the 3D printers, there is a laser cutter for individual model parts, a CNC milling machine, several polystyrene cutters that use a hot wire to cut polystyrene and similar materials quickly and accurately, a sandblasting machine, a light table and a laminator. The most recent acquisition is a cutting plotter, which can be used to cut foil and thin cardboard. In the carpentry workshop, students have access to a variety of (motorised) saws, sanders and other tools. The modelling workshop also includes a paint booth and an assembly room.

In addition to architecture students, students from other courses and universities can work on their projects here.

The workshop is open Monday to Friday from 9:00 to 13:00 and 14:00 to 18:00. Students are supervised by two technical staff and student assistants who teach them how to use the tools and machines.