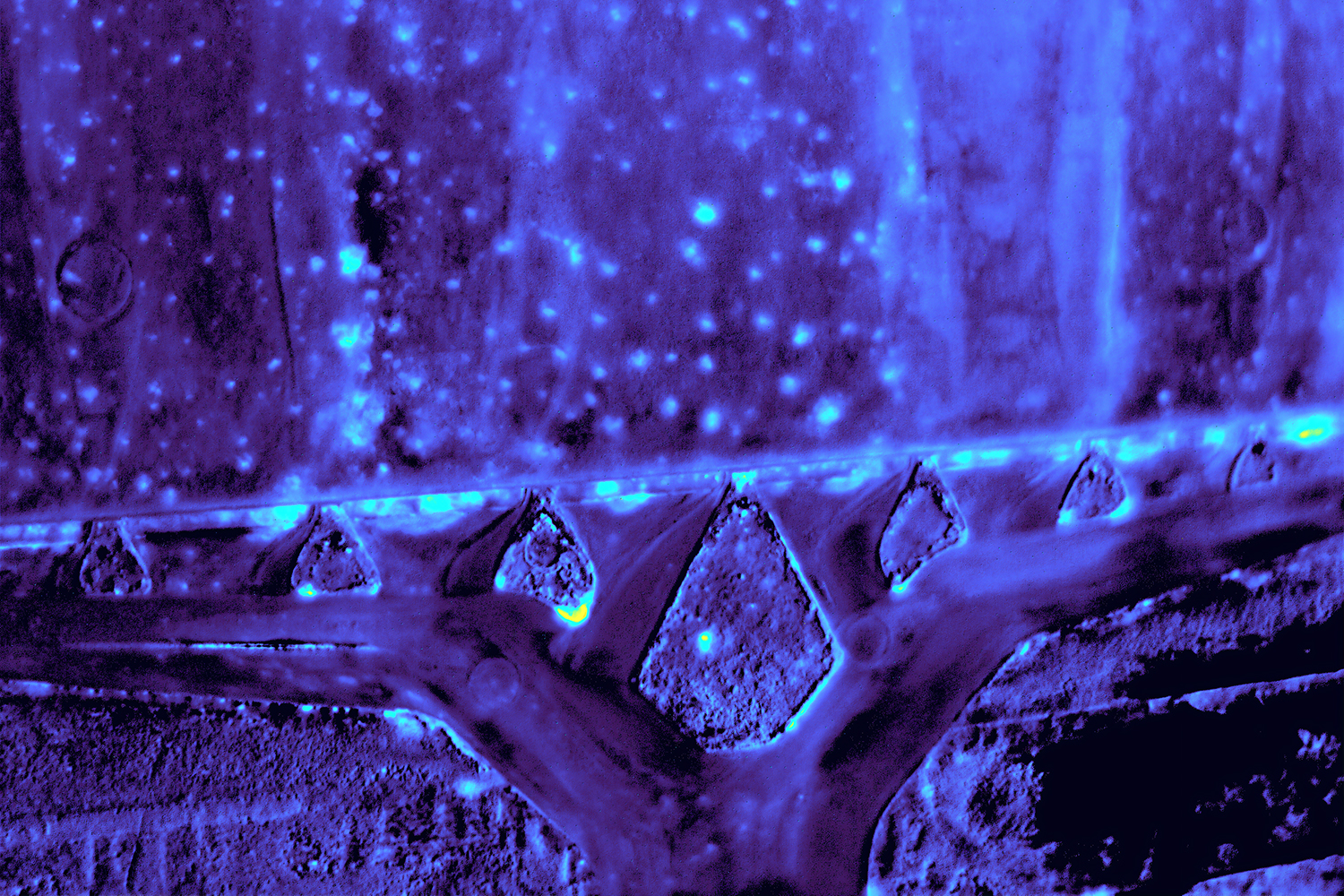

Picture of the month: Release agent coating of a die casting mould Optimisation of products and tools for metal casting

The picture of the month for June is an image from research into die casting at Technische Universität Braunschweig. Die casting is a process in which products are manufactured from metal. Sebastian Krischke’s fluorescence image shows the application of release agents to a die casting tool in false colour. The release agents applied to the surface of die casting moulds and components are made to fluoresce, i.e. glow, using ultraviolet light. This fluorescence is recorded by a camera. The researchers at the Institute of Joining and Welding Technology then use the intensity of the fluorescence to determine the relative amount of release agent on the surface.

Fluorescence image of the release agent coating of an aluminium die-casting tool. Photo credit: Sebastian Krischke/TU Braunschweig

Die casting is a particularly economical process for producing complex shaped products from light metals such as aluminium, used in the automotive, aerospace and household appliance industries, among others. The process involves forcing liquid metal into a steel mould at high speed and pressure. A release agent is sprayed onto the mould beforehand to prevent direct contact between the molten metal and the forming tool. This ensures that the part can be released from the mould and increases the life of the mould. However, the release agent residues on the part surface can affect the suitability of the parts for subsequent bonding, welding or painting processes, especially if too much release agent is applied. It is important that the application process is carefully designed to balance this trade-off, and that neither too much nor too little release agent is applied locally.

The RELEASE research project is investigating the extent to which this design can be supported by casting process simulation and implementing a method for monitoring and controlling the application of release agent in the casting process. Studies are also being carried out to measure the amount of release agent applied locally to the die and remaining on the component.

The camera used here produces images in greyscale, i.e. it only provides information about the brightness of each pixel. In false colour imaging, this brightness information is converted to a colour on a pre-selected colour scale to make the different levels of brightness clear. This principle is also used, for example, in thermal imaging cameras. In the context of the project, the brightness in the grey scale or the colour of the image in the false colour representation is intended to provide information about the intensity of the release agent occupancy.

The image was created as part of the IGF project RELEASE (“Reduktion des Formklebens im Aluminium-Druckgießprozess durch anforderungsorientierte Trennstoffapplikation“ (Reduction of mould sticking in the aluminium die casting process through demand-oriented release agent application), IGF no. 21.609N). The project of the Forschungsvereinigung Gießereitechnik e.V. (FVG) was funded via the DLR Project Management Agency (DLR-PT) as part of the programme for the promotion of joint industrial research and development (IGF) by the Federal Ministry of Economics and Climate Protection (BMWK) on the basis of a resolution of the German Bundestag.