How Hydrogen Production Can Be Optimised Technical Electrocatalysis Laboratory researches proton exchange electrolysis

Hydrogen plays an important role in the debate about future energy sources. One method of producing hydrogen is electrolysis. In this process, water is electrochemically split into oxygen and hydrogen. In order to build efficient large-scale plants while avoiding damage to the production equipment, various parameters of the electrolysers have to be optimised. Professor Mehtap Özaslan and her laboratory for technical electrocatalysis at Technische Universität Braunschweig have studied the transport and consumption of water in an electrolyser.

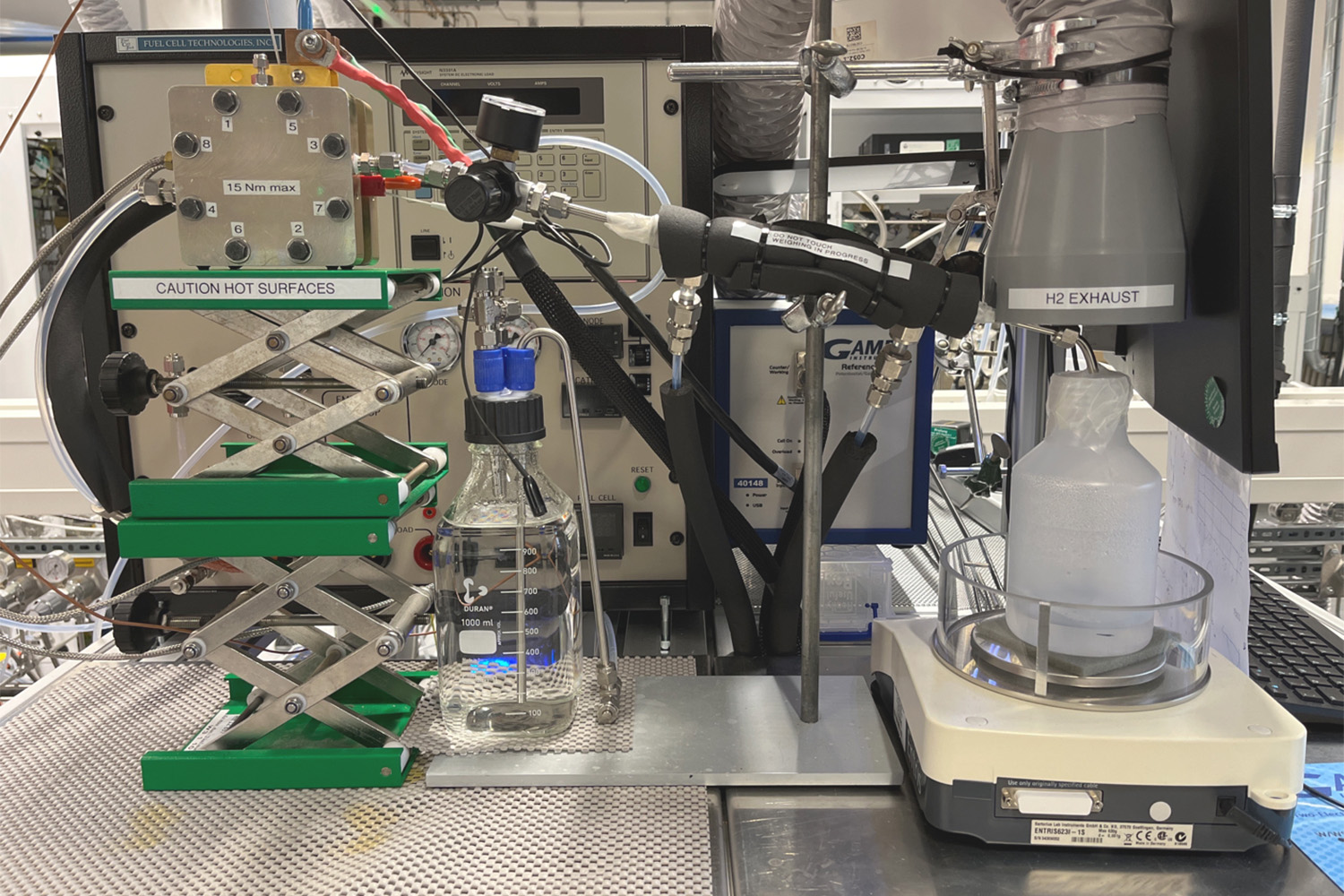

Experimental setup for the determination of water transport processes in PEM electrolysis at the Institute of Technical Chemistry. Photo credit: Technical Electrocatalysis Laboratory (ITEC)

There are several electrolysis technologies. The experiment at the Technical Electrocatalysis Laboratory investigated Proton Exchange Membrane Water Electrolysis (PEMWE). In this technology, water is consumed at the anode in an electrochemical reaction. Oxygen, protons and electrons are produced. A proton-conducting membrane is placed between the anode and cathode. The protons released at the anode can pass through this membrane to the cathode. The protons are then reduced to hydrogen at the cathode.

The process of transporting the protons from the anode to the cathode consumes a large amount of water. This water is then no longer available for electrolysis, as the water-consuming reaction takes place at the anode. In the paper, the team measured exactly how much water is transported to the cathode by the proton current. They found that the number of water molecules per proton depends on the temperature.

Important for plant engineering

This information is important for plant engineers to ensure that the electrolyser is supplied with sufficient water. Otherwise, damage will occur in the event of insufficient supply.

In addition, small amounts of gases are dissolved in water. This means that water transport has an influence on the purity of the hydrogen produced. Last but not least, the temperature dependence of water transport is an important parameter for modelling an electrolyser in order to be able to predict the system behaviour when operated with renewable energies. This is one of the objectives of the project “Hydrogen Terminal Braunschweig”, funded by the Federal Ministry of Education and Research (BMBF), a joint project of the Steinbeis Innovation Centre energieplus (siz energieplus) and Technische Universität Braunschweig (FKZ: 03EW0016B).

The results of this study were presented in a lecture at the 243rd Electrochemical Society Meeting in Boston, USA.