Electromobility: Managing sustainability in global supply chains Dr. Christian Thies awarded BME prize for dissertation

For many global companies, incorporating sustainability goals into the design and management of their supply chains has become a key success factor. But why is this so? On the one hand, it is necessary to meet stricter legal requirements, such as compliance with environmental and social standards, even beyond the company’s own boundaries (e.g., with suppliers). On the other hand, the consistent pursuit of sustainability goals can reduce risks in the supply chain, promote the corporate image, appeal to new customer groups and ultimately bring about competitive advantages.

Dr. Christian Thies. Bildnachweis: AIP/TU Braunschweig

However, according to Dr. Christian Thies, the approaches to sustainability assessment developed so far in the scientific literature have shortcomings. For example, often only individual dimensions of sustainability are considered. “There is a lack of integration of economic, ecological and social aspects into a holistic assessment approach. In addition, regional differences in global supply chains are insufficiently mapped and often only averaged or generic process data is used, which does not reflect the real design of the supply chain appropriately. In many applications, this can lead to erroneous results,” says Dr. Thies, who was awarded the BME Wissenschaftspreis 2021 for his dissertation. Since 1988, the association has awarded the prize to scientists who have presented an outstanding post-doctoral thesis or dissertation on the topics of purchasing, supply chain management and logistics.

Regional specifics in global supply chains

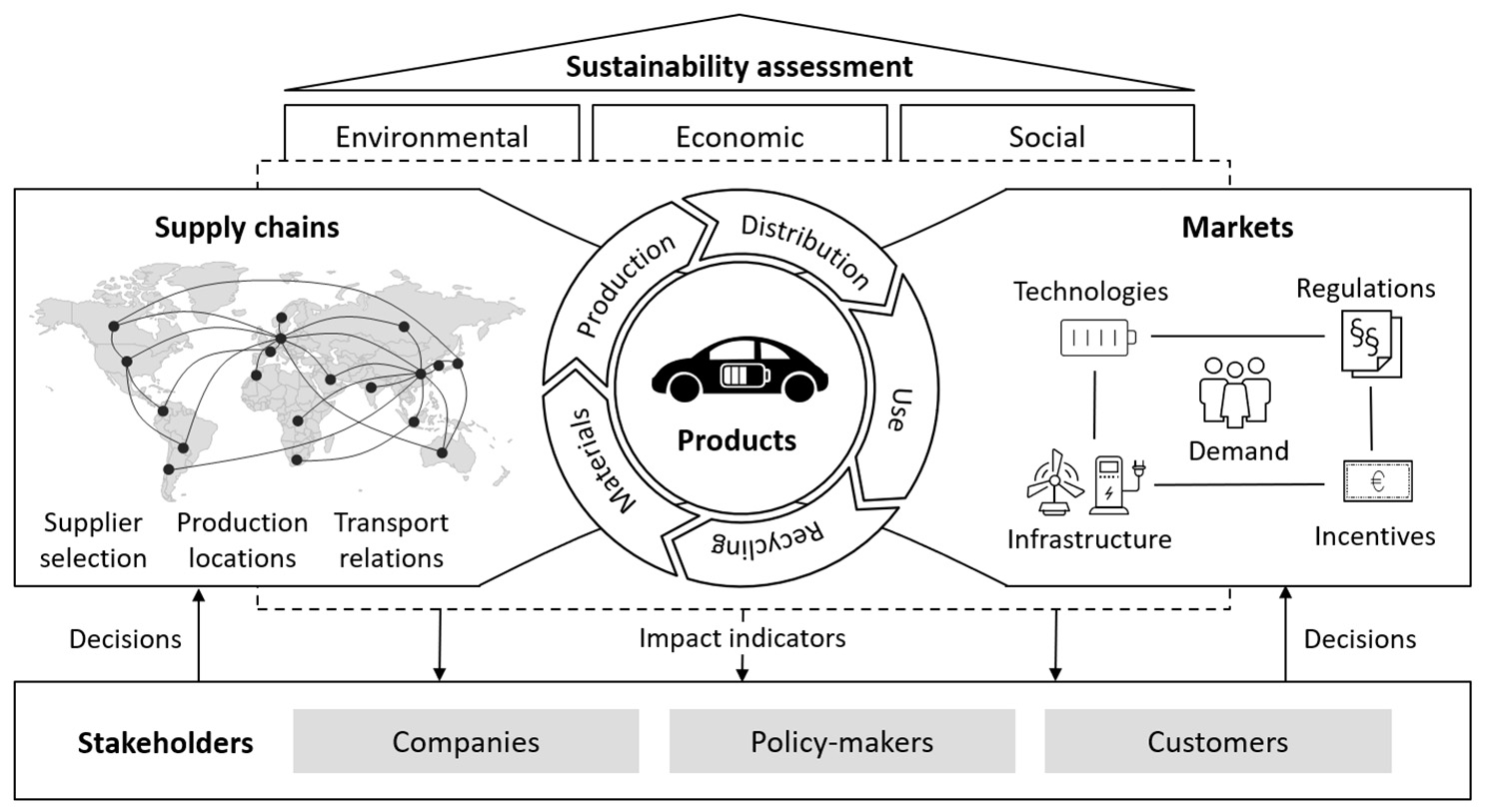

Based on the research gaps, Dr. Thies developed a new concept for a sustainability assessment as well as a modeling methodology based on the activity analysis long established in economics and business administration by the two Nobel Prize winners in economics, Tjalling C. Koopmans and Gérard Debreu. He expanded the method to include not only economic criteria but also environmental and social aspects in the assessment and to take into account regional specifics when modeling global supply chains.

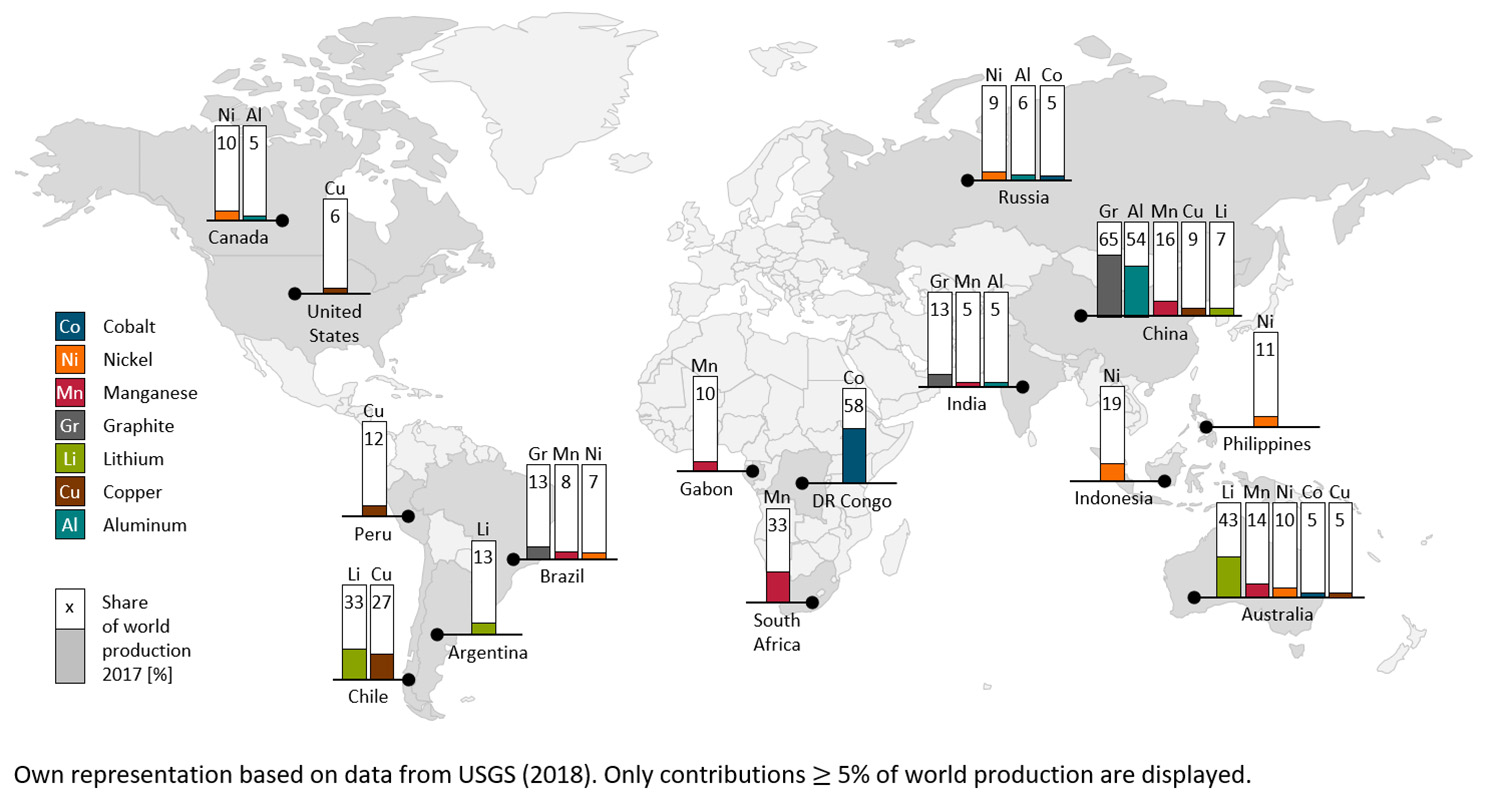

Global distribution of supply chains: production of key battery raw materials, measured as a share of global market production in 2017. Image credit: Christian Thies/TU Braunschweig

Finding “sustainability hotspots”

As a result, the work provides assessment principles that can be integrated into strategic and operational supply chain management. With this tool, business decision-makers can better design supply chains. They will have a better view of which entrepreneurial steps (supply relationships, production locations, distribution structures, etc.) affect the environment, economic effort and success, as well as society, and to what extent. “By explicitly mapping the connections between business decisions and environmental, economic and social impacts, sustainability hotspots can be identified and improvement measures can be directly evaluated.”

Dr. Thies’ approach also offers another benefit: “Industrial companies are supported in making the impacts in their supply chains more transparent and ultimately reducing them, as is increasingly demanded, for example, in the current debate about the planned Supply Chain Act.”

Reference framework for sustainability assessment of products with global supply chains. Photo credit: Christian Thies/TU Braunschweig

Application in the field of electromobility

Dr. Thies shows how the knowledge can be applied in concrete terms in the field of electromobility. One example: lithium-ion batteries are one of the key components of electric vehicles. The supply chain of batteries is associated with enormous ecological impacts and social risks, especially in the extraction of raw materials and in battery cell production. These can be positively influenced by companies through a targeted design of the primary raw material supply chain, but also through the use of new recycling technologies to recover the valuable raw materials.