Dr Inka Mai receives Klaus Dyckerhoff Prize for Young Scientists Research on 3D printing of concrete awarded

The diversity of research questions is what Dr Inka Mai values most about additive manufacturing. And the potential to save material in construction and thus to work more ecologically in the future. For her research on 3D printing of concrete, the senior engineer at the Division Building Materials of the Institute of Building Materials, Concrete Construction and Fire Safety (iBMB) is now receiving the “Klaus Dyckerhoff Award for Young Scientists” together with Dr. Lei Lei from TU München. The award was shared between the two researchers in 2021.

For her application-oriented research on 3D printing of concrete, Dr Inka Mai received the Klaus Dyckerhoff Prize 2021. Picture credits: Studioline

The board of trustees and the award jury thereby recognise the overall scientific achievements of Inka Mai at the iBMB, which has developed into a development centre for innovative concrete construction methods, especially 3D printing, according to the jury’s statement. In particular, two papers published in the journal “Materials” were highlighted: “The Effect of Accelerator Dosage on Fresh Concrete Properties and on Interlayer Strength in Shotcrete 3D Printing” and “Injection 3D Concrete Printing (I3DCP): Basic Principles and Case Studies”.

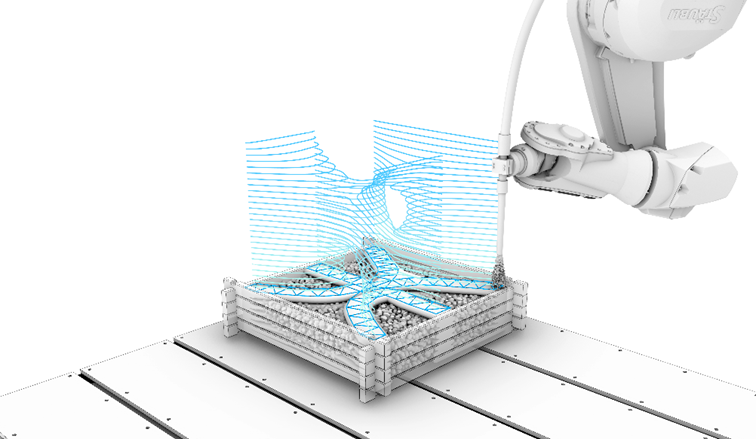

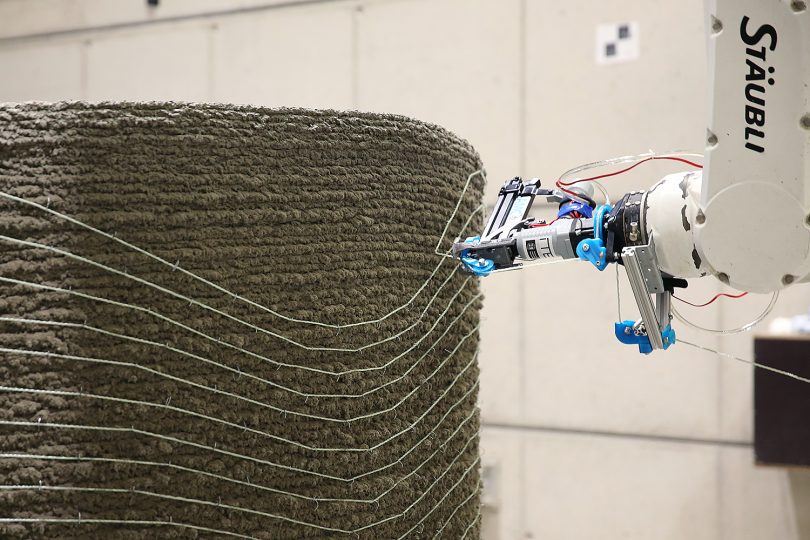

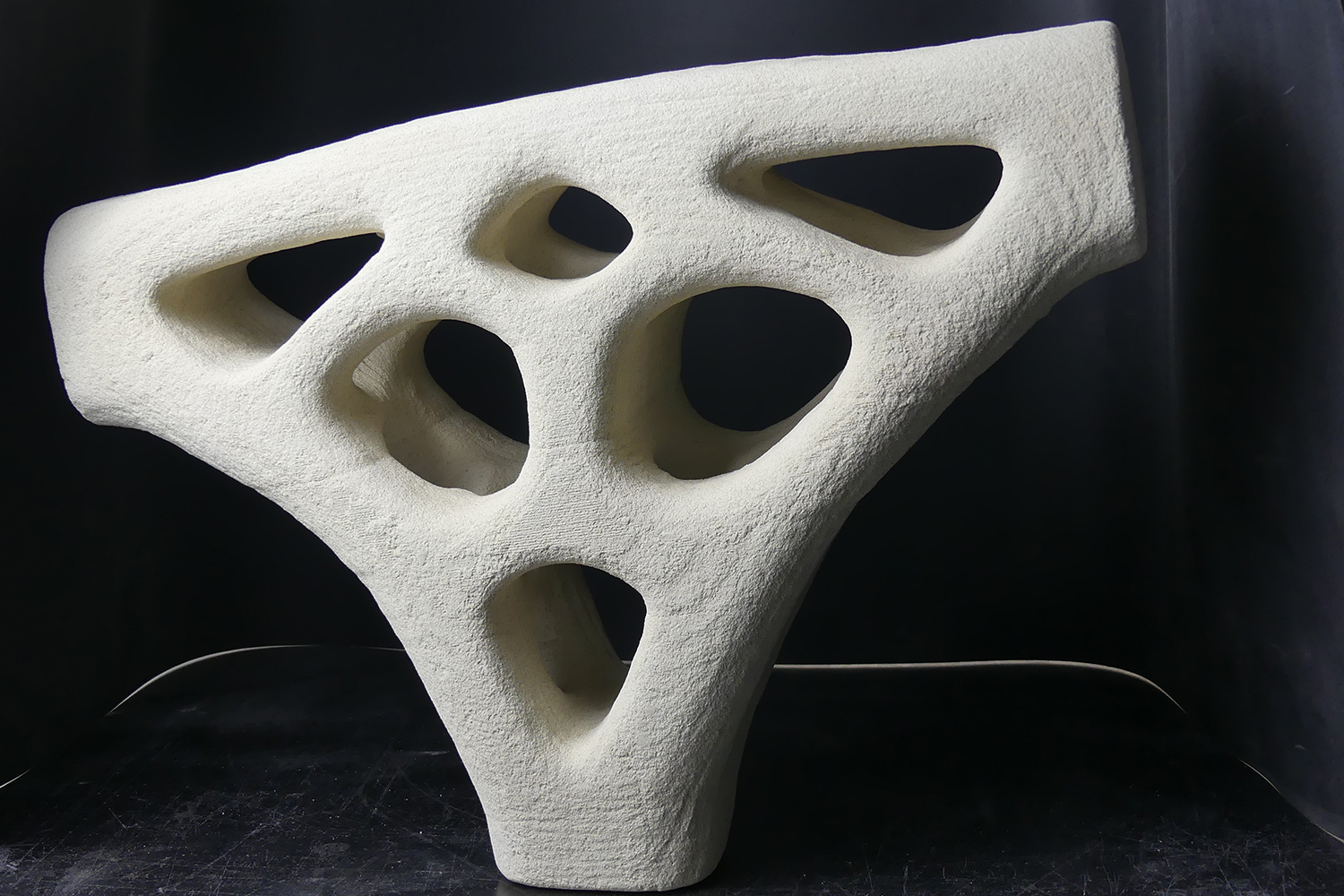

In particular, it is thanks to Dr Inka Mai that previously unknown process variants were also found and tested, such as working with injection processes in suspensions (Injection 3D Concrete Printing) or the application of shotcrete on particle beds (Large Particle 3D Concrete Printing), the jury said. “She takes into account not only the technological requirements of the product, but also resource efficiency, climate contribution, practical feasibility and costs. Only this broad range of competencies can help 3D printing of concrete achieve a sustainable market share.”

A topology-optimised node created using particle bed prints. Design: Prof. Harald Kloft. Production and image: iBMB/TU Braunschweig

Research in the SFB TRR 277 AMC

Since 2019, Inka Mai has headed the “Rheology and Digital Manufacturing” working group at the Division Building Materials of the iBMB and focuses on additive manufacturing and the related processing of cement-bound building materials. She is also conducting research in two projects of the Collaborative Research Centre Transregio 277 Additive Manufacturing in Construction (AMC) and expanded her expertise on the particle bed 3D printing process during a AMC-funded research stay in France.

Although Germany’s first 3D-printed house was recently built and the methods of digital production with concrete are gaining maturity, there are still quite a few hurdles to overcome before 3D printing with concrete and other digital concrete construction methods can be standardised and transferred into building practice, says Inka Mai. “Overcoming these hurdles can only be successful if the material-process interaction of the respective processes is fundamentally understood,” she emphasises. “This includes, among other things, analysing active control options for cement hydration and the rheology of cement-based building materials, as well as investigating the effects of various material and process parameters on the mechanical and geometric properties of the 3D-printed concrete component.”

From Particle Bed to Injection 3D Printing

Inka Mai and the scientists of the Division Building Materials are successfully conducting research in this field. In addition to several particle bed 3D printing processes, her research also focuses on shotcrete 3D printing and injection 3D printing, which can be used to create completely free form elements. Furthermore, she is also very well networked internationally in this research area, for example through the “RILEM Technical Committee for fresh properties of printable materials”.

“I am very pleased that my work in this exciting and innovative field is being recognised with this prize,” says Inka Mai. The Klaus Dyckerhoff Prize for Young Scientists 2021 also goes to Dr Lei Lei from TU Munich. The award ceremony will take place in June during the Ulmer BetonTage.

A Shotcrete 3D Printing process in the Digital Building Fabrication Laboratory (DBFL) in the experimental hall at Beethovenstraße. Picture credits: ITE/TU Braunschweig

About the Prize

The Dres. Edith and Klaus Dyckerhoff Foundation promotes research into building materials. Since 2021, the “Klaus Dyckerhoff Prize for Young Scientists” has been awarded for publications by young scientists on the research, application or production of binding agents and their additives. The prize is currently endowed with 10,000 euros and is awarded every 18 months. In 2021, it was awarded in equal shares to Dr Inka Mai from TU Braunschweig and Dr Lei Lei from TU Munich.

The foundation also invites applications for multi-year research projects. In 2020, Professor Dirk Lowke from the Institute of Building Materials, Concrete Construction and Fire Safety was awarded a grant on the topic of “Sustainable concretes from locally available raw materials”.