Biotech on a budget Braunschweig biotech team wins €99 bioreactor competition

Bioreactors are used in biotechnological research and industry to carry out biological reactions under optimum reaction conditions (e.g. temperature, pH and oxygen content). They are mainly used in the production of pharmaceutical products, basic chemicals from renewable resources, food and cosmetics, and in biological processes in environmental technology. At the end of the 2024 summer semester, the Netzwerk Bioverfahrenstechnik Dresden e. V. organised the renowned “99 € Bioreactor Competition” at the Institute of Natural Materials Technology at TU Dresden for the ninth time. This time, the winner was the team from TU Braunschweig.

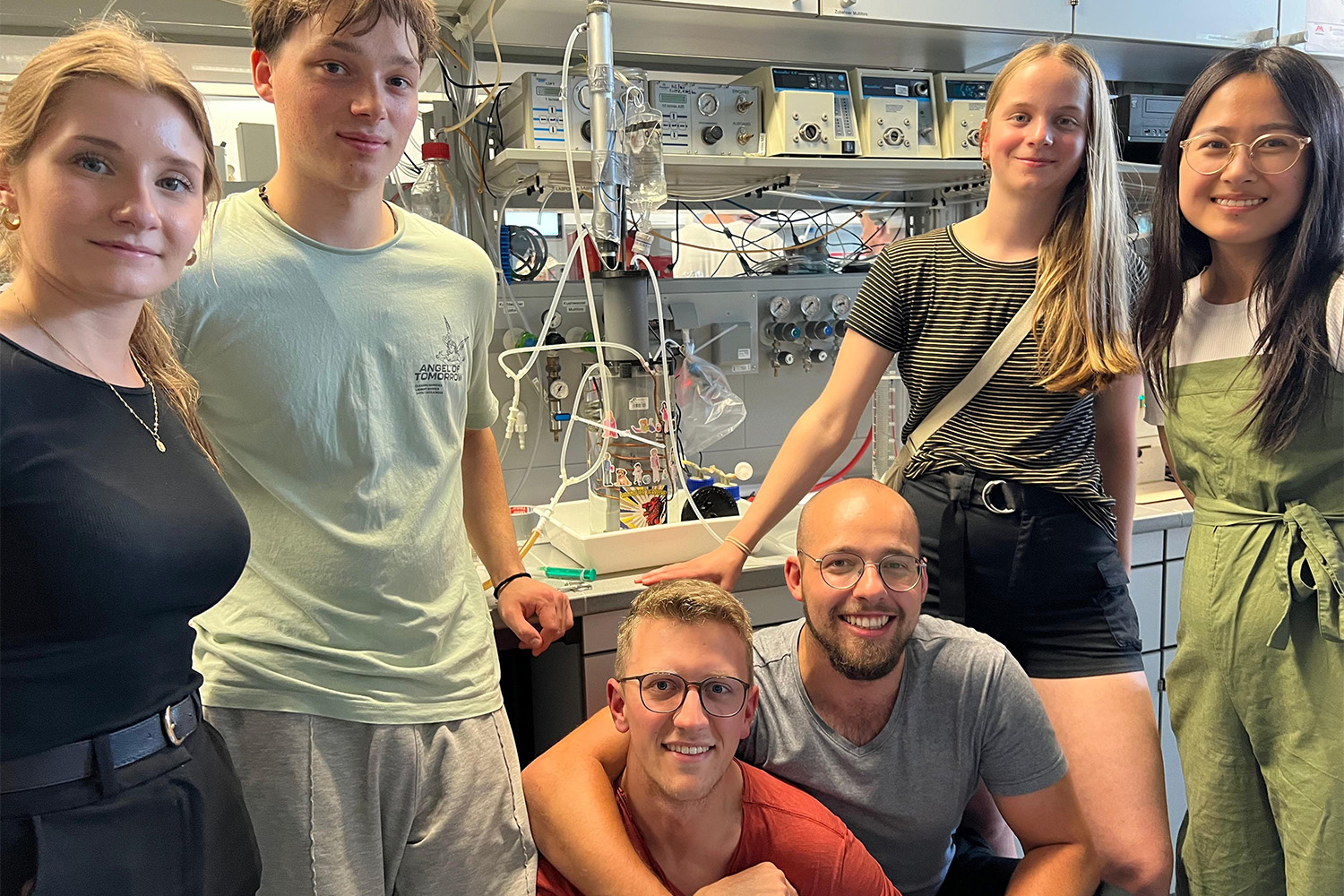

The Braunschweig biotech team with their bioreactor design for polyglutamine biopolymer production at the €99 bioreactor competition at TU Dresden (from left to right): Nathalie Opilo, Theo Weise, Leon Huß, Dorian Röhring, Elisa Lädke (all Biotechnology, Bioprocess Engineering students) and Julia Li (exchange student in the TU Braunschweig-University of Waterloo programme). Photo credit: Anwar Walid (ibvt)

The aim of the “€99 Bioreactor Competition” is to develop and build a laboratory bioreactor for a biotechnological task with a budget of only €99 and then to compete against other teams in the cultivation competition. Seven biotech teams from the Universities of Munich and Mittweida, TU Dresden and HTW Dresden, Friedrich-Alexander-Universität Erlangen-Nürnberg, Karlsruhe Institute of Technology and TU Braunschweig took part in this year’s competition.

This time, the “Microbe of the Year 2023” was Bacillus subtilis (lat. bacillus, rod; subtilis, fine, simple). Bacillus subtilis is used to produce the traditional Japanese food Nattō. Soybeans are cooked and then cultured under the influence of the bacterium Bacillus subtilis var. natto, which increases their viscosity. Nattō is served as an accompaniment to other dishes, used as an ingredient (e.g. as a thickener) and eaten by itself. It has health benefits and is easily digested by Bacillus subtilis.

The challenge of this year’s competition was to use Bacillus subtilis var. natto for the biotechnological production of the biopolymer polyglutamic acid (PGA). PGA is a major component of Nattō, which determines the viscosity-increasing properties of the culture medium. PGA is edible, biodegradable, water soluble and non-toxic. In the pharmaceutical industry, PGA is used as a drug delivery system because the biopolymer is immunologically neutral. The aim was to achieve the highest possible viscosity and concentration of the biopolymer in the cultivation medium in a 24-hour cultivation process using a self-designed bioreactor.

The biotech team from TU Braunschweig, consisting of students Nathalie Opilo, Theo Weise, Leon Huß, Dorian Röhring, Elisa Lädke (all studying Biotechnology, Bioprocess Engineering) and Julia Li, who is on a four-month research stay at the Institute of Bioprocess Engineering as part of the DAAD exchange programme with the University of Waterloo, Canada, rose to the complex challenge and took first place. Anwar Walid and Jan-Angelus Meyer from the Institute of Biochemical Engineering supervised the Braunschweig biotech team and guided them through the competition.

At the start of the competition, participating teams had three hours to set up their pre-engineered bioreactor on site. The culture medium in the bioreactors was then inoculated with the Bacillus strain to start biomass and PGA production. The cultivation process was run for 24 hours without any interaction. The student team from TU Braunschweig not only scored with the highest (dynamic) viscosity. The team was also in the top group for minimising evaporation losses with a total budget of only €92.19.

The competition is challenging. Students apply what they have learnt in their bioprocessing lectures and also in their laboratory courses under challenging conditions, such as adherence to economic specifications, use of certain basic operations such as homogenisation and mixing, and consideration of product properties. Participants are required to have a wide range of skills: application of sophisticated cultivation techniques, specialised methodological knowledge, design and craftsmanship in the mechanical workshop, application of measurement and control concepts, and often pragmatic solutions and approaches. This is because the micro-organism often does not do what is expected of it.

The joint development, construction and experimentation paid off for the team. TU Braunschweig students’ bioreactor met the competition’s criteria in an excellent way.

We would like to congratulate the biotech team at TU Braunschweig on this great success.

The preparations and preliminary work of the biotech team at TU Braunschweig were kindly supported by government funding for educational quality from the Faculty of Life Sciences, Department of Biotechnology, and the Fördergesellschaft Chemie- und Bioingenieurwesen Braunschweig e.V. (Institute of Biochemical Engineering, TU Braunschweig).

Author: Prof. Rainer Krull