Recycling for Future: Building with waste wood TU Braunschweig investigates circular economy in the construction industry

Wood is a sought-after raw material – now more than ever: consumption has risen sharply in recent years, partly because more and more houses are being built from wood. As a result, the processing of waste wood and the development of recyclable wood components are becoming increasingly important. Scientists at Technische Universität Braunschweig, together with industrial partners, are investigating how as much wood as possible can be recycled and kept in the material cycle. The two research projects “Recycling for Future” and “Recycling for Reuse” on resource-saving construction are being funded by the Agency for Renewable Resources (FNR) with a total of around 2.4 million euros.

Germany produces between seven and eight million tonnes of waste wood every year. Photo credit: Joshua Hoehne/Unsplash

Germany produces between seven and eight million tonnes of waste wood each year. The greatest potential for reuse is in waste wood from construction and demolition work, especially roof trusses, ceiling beams and prefabricated building elements. However, only around 20 per cent is recycled, mainly into chipboard, which can then be used to make new furniture and doors. The majority is used thermally to generate energy.

“The focus, however, should be on the sustainable and resource-efficient use of wood as a raw material and its multiple reuse,” says Professor Mike Sieder, head of the Institute for Building Construction and Wood Technology (iBHolz) at TU Braunschweig. In this so-called “cascade utilisation”, the carbon stored in the wood remains in the wood products for as long as possible beyond the life of the tree, until the wood material that can no longer be used sensibly is burned to generate energy and the bound carbon dioxide (CO2) is released again at the end of the long use or life cycle.

Complex material mix in prefabricated construction

At the heart of the “Recycling for Future” project is the so-called timber panel – a flat, load-bearing timber structure that is widely used in house building. However, its recyclability has been severely limited until now. The problem lies in the material mix of metallic, organic and mineral components. Apart from the fact that it is very difficult to dismantle a complete panel into its individual components, these individual components are themselves made up of hybrid materials that cannot necessarily be separated by type, such as plasterboard (gypsum and paper), wood-based materials (wood and glue), insulation materials made from a wide variety of raw materials and additives, and possibly mineral or synthetic resin-based plaster systems.

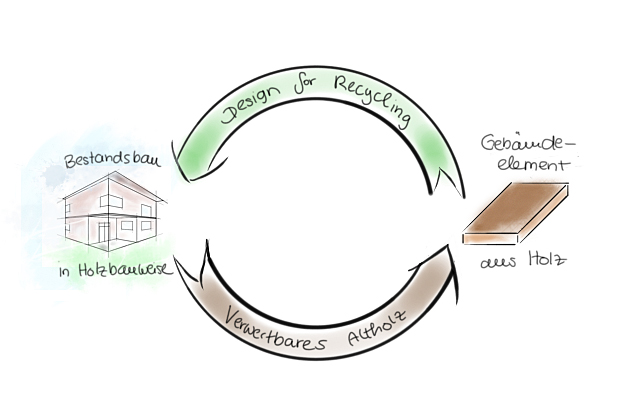

It is therefore not easy to remove and replace individual components of a wooden panel to obtain a more recyclable product. The aim of the research project is therefore to develop easily and highly recyclable wooden panel elements that consist of as few different components and materials as possible and can be kept in the material cycle in the long term, in line with the concept of “urban mining” (recovery of raw materials from urban construction) – i.e. they are not disposed of after a single use. “We want to optimise the entire wood panel system,” says Professor Sieder. “From the manufacture of the individual components and the production of the wooden panel to dismantling, recycling and reuse.” The project therefore involves TU Braunschweig, the Fraunhofer Institute for Wood Research WKI and Ruhr University Bochum, as well as a manufacturer of timber panel buildings, suppliers and recycling companies. “An ecological and sustainable recycling cycle for a timber panel can only be created if all those involved sit down together and contribute their expertise in an interdisciplinary exchange,” emphasises Professor Sieder.

Recycling-friendly prototype

The project partners will work together to analyse the decomposability and possible separation of individual wooden panels by type in order to derive evaluation parameters for the design and production of an ecological, economical and recyclable wooden panel. In addition, current recycling processes will be reviewed and a concept for secondary use will be developed, so that the raw materials can later be used in the manufacture of reusable products. At the end of the project, the partners aim to produce a prototype of a resource-efficient wood panel.

The scientists are investigating how as much wood as possible can be recycled and kept in the material cycle. Photo credit: iBHolz/TU Braunschweig

Processing waste wood for reuse “in non-visible areas”

The “Recycling for Reuse” project is also concerned with bringing the raw material wood back into the cycle: the scientists want to process waste wood so that it can be reused in the manufacture of structural components. Until now, pollutants from wood preservatives, surface protection, coatings or fire retardant additives have made reuse difficult. “For this reason, waste wood from the demolition of buildings must be treated in such a way that it is considered harmless in accordance with the Waste Wood Ordinance. The wood must not be chemically contaminated and must have the required strength,” explains Professor Sieder. The frequent use of wood in “non-visible areas” offers great potential for the reuse of waste wood, as “visual defects” are not a criterion for exclusion. This includes construction timber, sawn timber and solid structural timber.

Detection of foreign objects and wood preservatives

To this end, the scientists will work with industry partners to determine the amount of potentially recyclable waste wood. They will also develop mechanical processes to detect and remove metallic contaminants and wood preservatives in the wood used. The aim is to develop classification rules for the reuse of the building material and a holistic reuse concept in the form of a schematic process plan.

For Professor Sieder, in addition to the sustainability aspect, economic efficiency also plays a role in the use of waste wood: “Until now, timber construction has benefited from relatively low material costs, but these are associated with long transport routes from regions with non-ecological forestry. As the wood resources typical of the German construction sector are becoming increasingly scarce, while the use of wood in construction is increasing, material costs are expected to rise. Recycling waste wood can be an answer to the predicted rise in material prices in the future”.

Project data

Both projects are funded by the German Agency for Renewable Resources (FNR) for three years from 1 January 2024 to 31 December 2026.

Recycling for Future – Concepts for the recycling-friendly production of timber panel constructions

The aim of the research project is to develop easily and comprehensively recyclable timber components (timber panels) that can be retained in the material cycle for as long as possible. The project is being funded with €1.1 million, of which around €317,000 will go to the Institute of Building Construction and Timber Engineering (iBHolz). In addition to iBHolz, the project partners are the Fraunhofer Institute for Wood Research WKI (Braunschweig), the Chair for Resource-Efficient Building at Ruhr University Bochum, Otto Baukmeier Holzbau – Fertigbau GmbH & Co KG (Hameln), Sto SE & Co. KGaA (Stühlingen), Fermacell (James Hardie Europe GmbH, Düsseldorf) and ALBA Braunschweig GmbH.

Recycling for Reuse – Evaluation and processing of waste wood for recycling as part of a reuse concept

In this research project, the scientists will develop the basis for a methodology that enables the production of structural components and wood-based materials from bar-shaped waste wood. The funding amounts to a total of €1.3 million, of which around €379,000 will go to the Institute of Building Construction and Timber Engineering and €287,000 to the Institute of Machine Tools and Production Engineering (IWF) at TU Braunschweig. In addition to iBHolz and the IWF at TU Braunschweig, the Fraunhofer Institute for Wood Research WKI, the Leipzig University of Applied Sciences (HTWK), Peiner Entsorgungsgesellschaft mbH, Nibelungen Wohnbau GmbH (Braunschweig), Ing.-Holzbau SCHNOOR GmbH (Burg near Magdeburg), RINNTECH-Metriwerk GmbH & Co. KG (Heidelberg), Schumann-Analytics (Einbeck) and MICROTEC Srl (Brixen, Italy).