Picture of the Month: The quadrature of lightning From the elenia Institute for High Voltage Technology and Power Systems

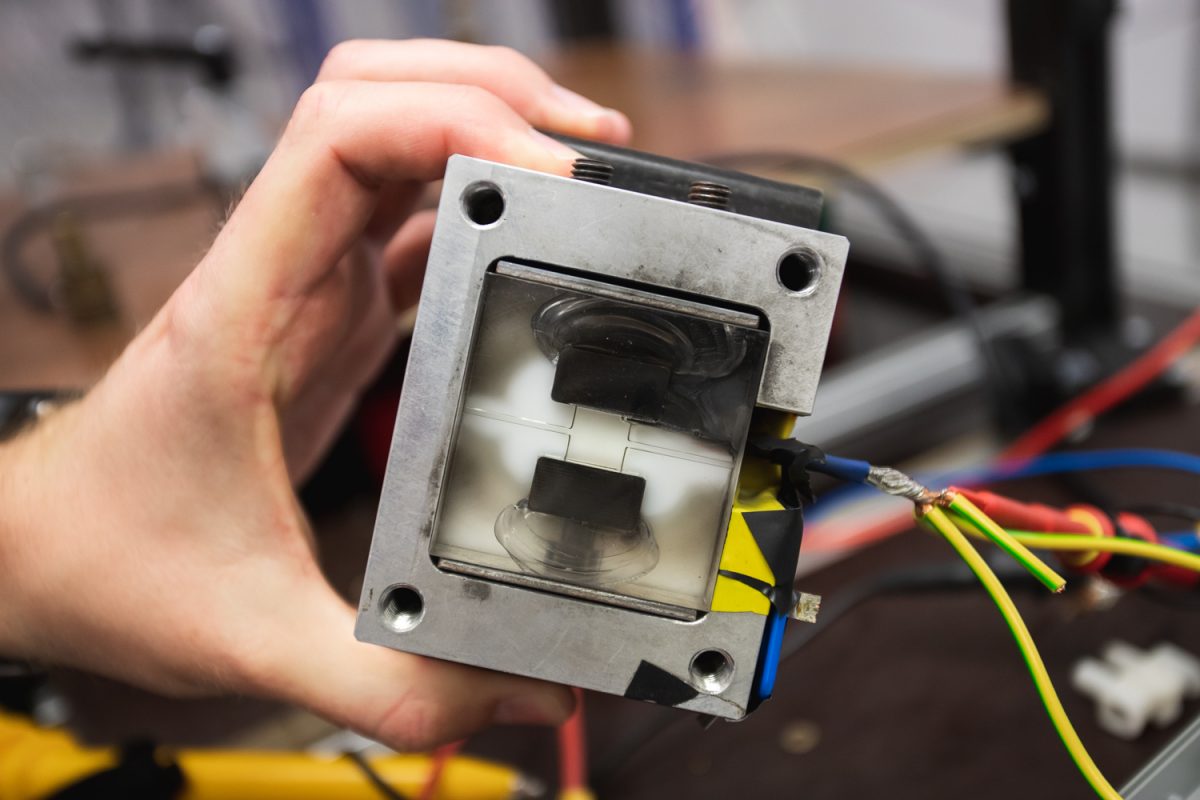

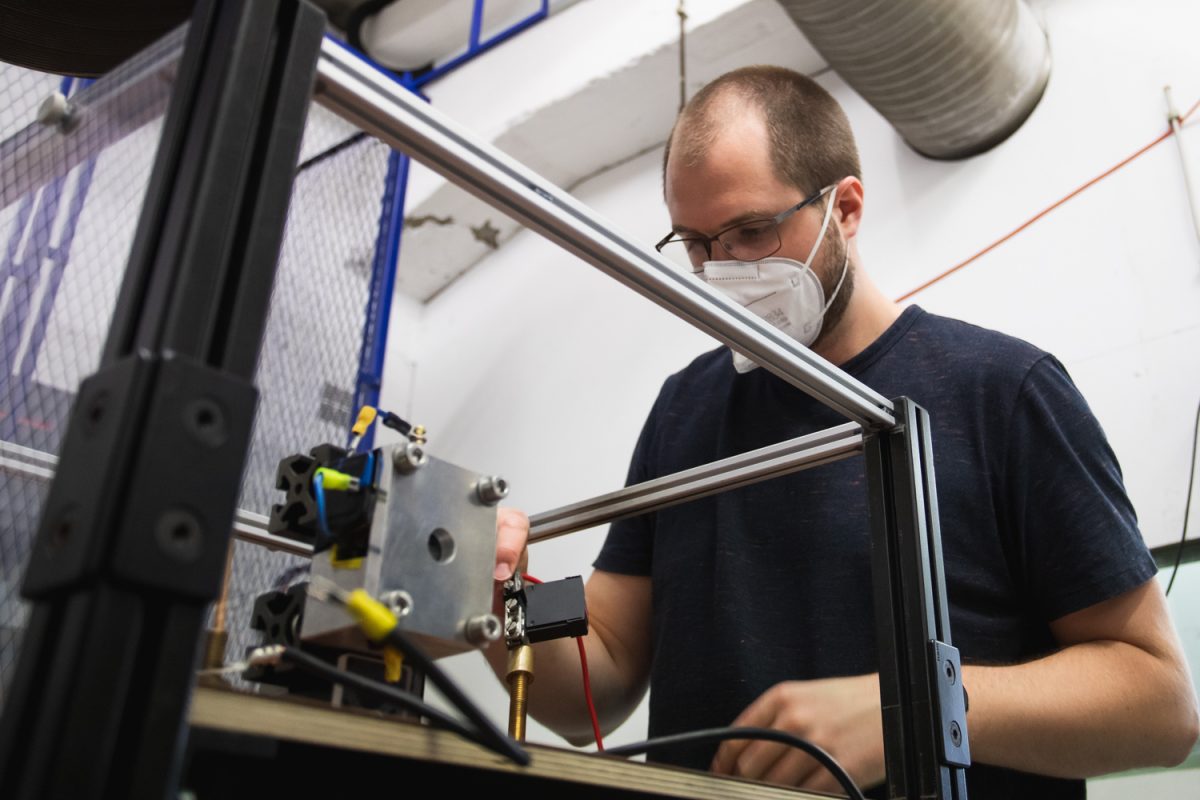

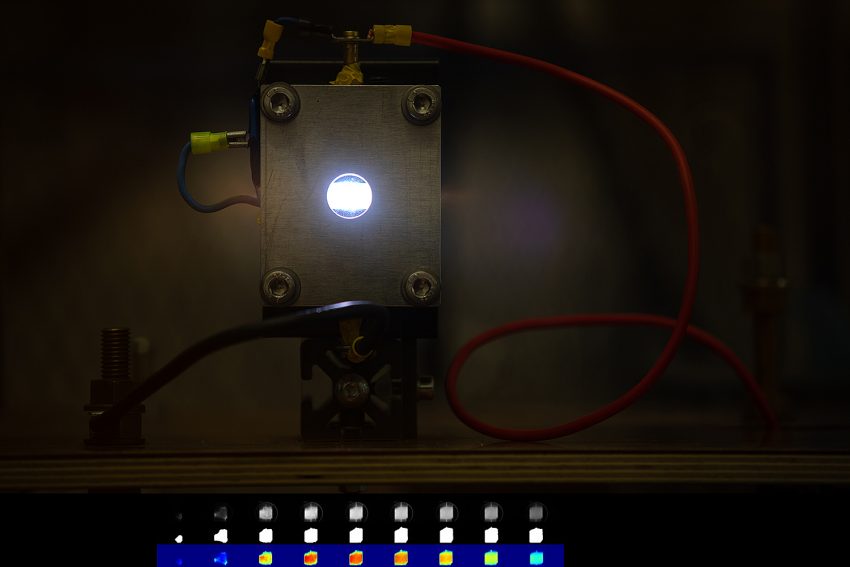

Our picture of the month captures the split seconds that decide the lives of people, but also devices such as refrigerators and computers, when lightning strikes. The extremely hot plasma in the photographed spark gap can be the saving short circuit for people and devices. The white and colored squares at the bottom of the picture come from the high-speed camera in the lightning protection laboratory of the elenia Institute for High Voltage Technology and Power Systems. Doctoral student Enno Peters uses it to research what effectively protects against lightning damage.

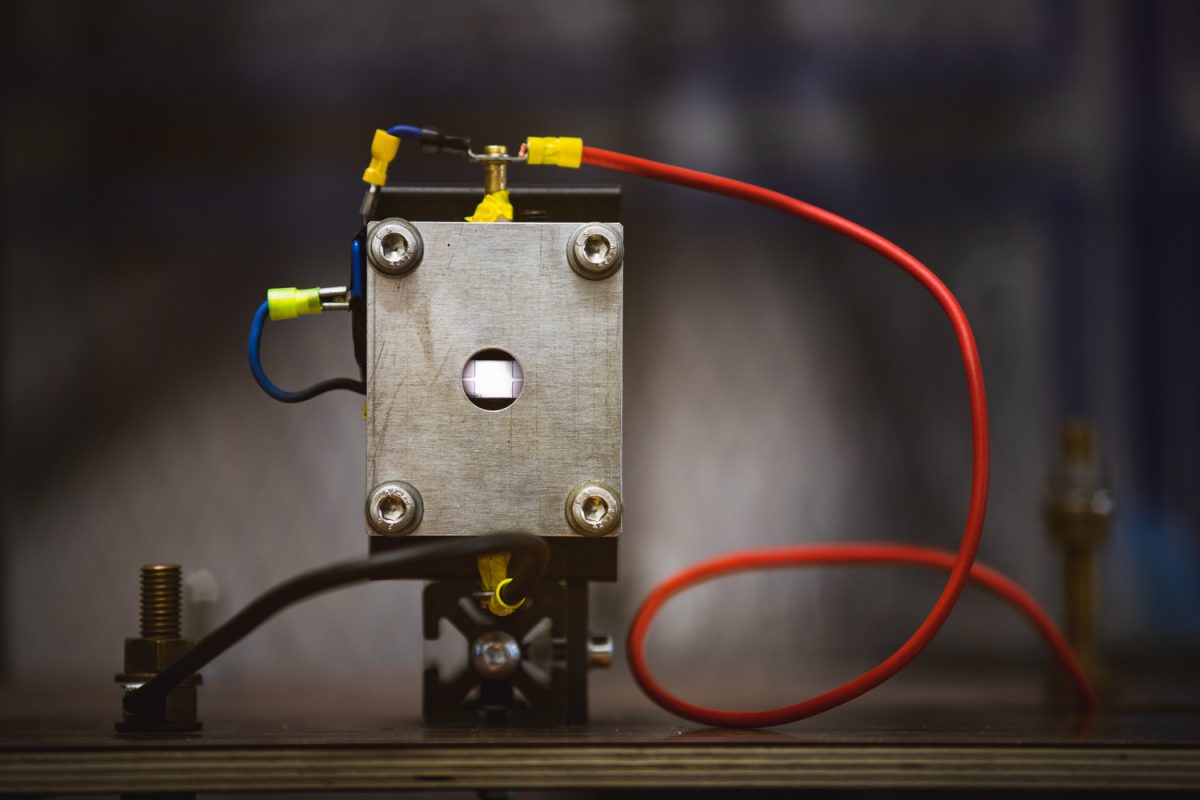

The spark gap in action. Below, the differently processed images from the high-speed camera. The top row is the original images, below that are the objects detected by the software, and then the colored objects. Picture credits: Max Fuhrmann/TU Braunschweig, Germany

The lightning protection system distinguishes between external and internal lightning protection. On the outside, lightning rods, connected to the grounding system, protect the building structure. Thus, lightning is more likely to strike the intercepting rod, whereupon the external lightning protection can discharge it to ground in a controlled manner. Inside the building, despite lightning rods, the risk of surge remains. “When lightning strikes the external system, it generates high currents and voltages. Normal insulation has little to counter the extraordinarily high lightning current and the resulting high voltage. Everything that is then still plugged into the socket would be toast. Moreover, this does not only apply to strikes directly at the house. Even if there is lightning within several kilometers, this can lead to overvoltage in the buildings,” explains doctoral student Enno Peters.

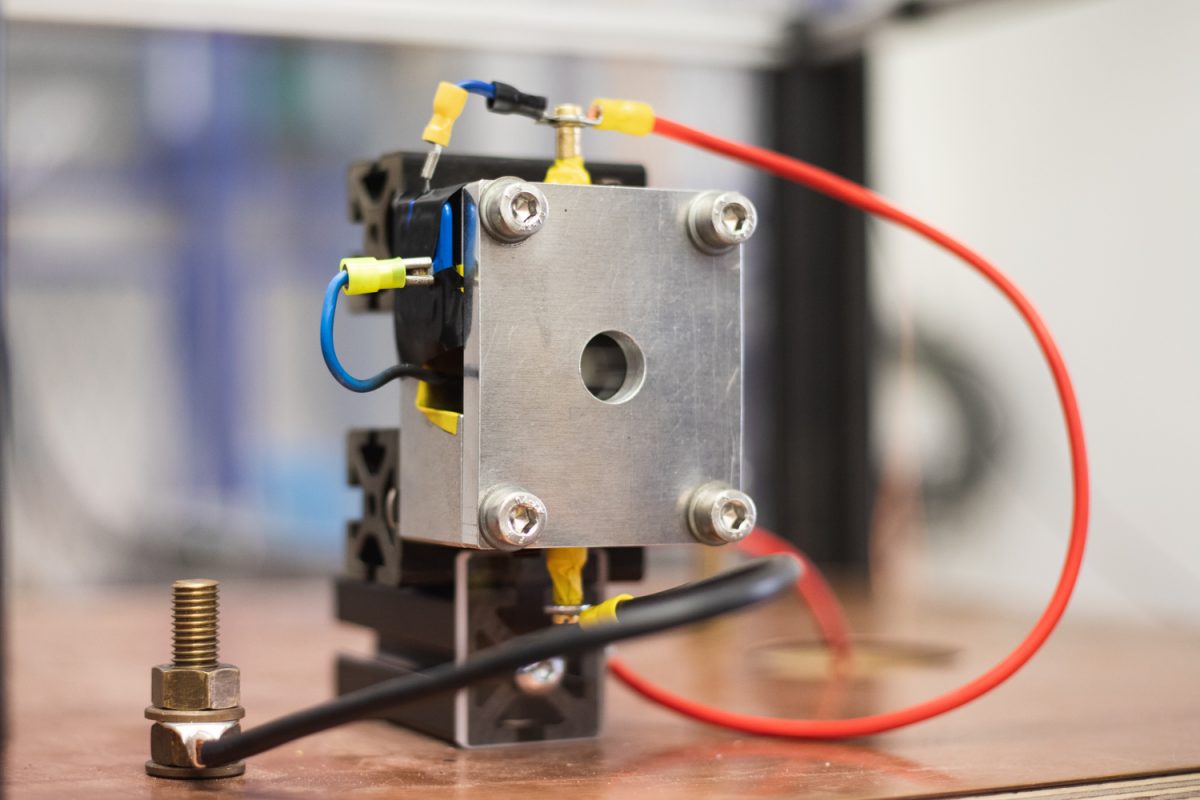

A fist-size box against 20,000 amperes

Lightning current arresters, which at their core consist of a so-called spark gap, help against the high-energy lightning current. It contains two electrodes separated by air. When lightning abruptly drives up current and voltage, the air becomes plasma and thus conductive. An electric arc forms, similar to that of some welders. This arc can be the saving short-circuit.

The picture of the month shows such an arc of plasma in a spark gap in the lightning current laboratory. The spark gap, which is about the size of a fist, is hardly any different from those protecting industrial buildings or private homes. Only on one side is the hull material made of a transparent plastic so that the high-speed camera can photograph into it. “The German Research Foundation (DFG) was a great help with the camera,” says Enno Peters. “Since the flash is only in the spark gap for a few microseconds, we needed an extremely fast camera. Ours manages 800,000 frames per second. So with that, we get about ten images of each arc.”

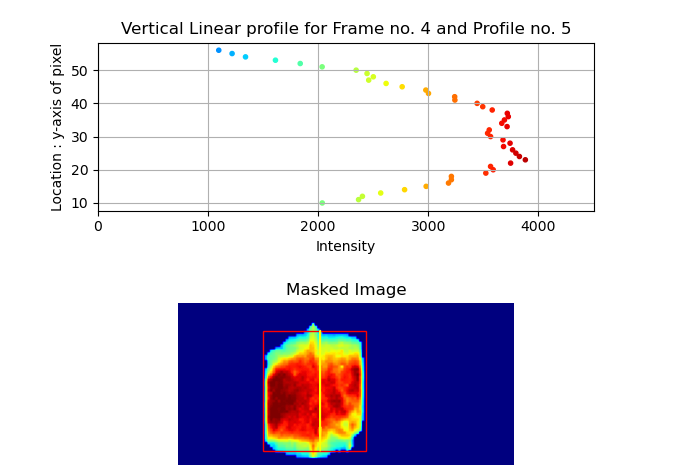

Current per pixel

Through the eye of the high-speed camera: with suitable software, Enno Peters analyzes the plasma in the spark gap frame by frame. The graph gives the local current distribution (yellow line) on a scale from 0 to 4095: This number corresponds exactly to the 12bit resolution of the camera. Picture credits: Enno Peters/TU Braunschweig

To better analyze the black and white camera images, PhD students Benjamin Weber and Enno Peters programmed an analysis software together. This marks the current distribution with a color code: The redder, the higher the current. At the same time, it immediately recognizes the relevant area of the arc (red box) and creates line profiles that indicate the current density per pixel across the current flow (yellow line and diagram). The research shall reveal how the plasma is distributed locally in the spark gap. “Several tens of thousands of amperes, temperatures up to 30,000 Kelvin and a pressure of over 500 bar: Even a lightning current arrester can’t withstand that too often. As side effects, if we know the distribution of the plasma, we can make statements about material burnup at the electrodes and combustion chamber. Another open question is how the device returns to its initial state. With this knowledge, the devices could be improved even further in the long term,” says Enno Peters.