Picture of the month: Biscuits for Quantum Computers From the Quantum Valley Lower Saxony

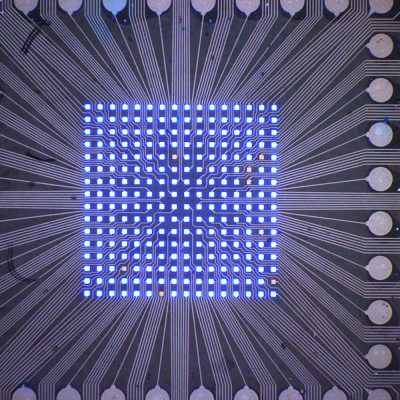

The picture of the month December shows a so-called ‘wafer’. Every person reading this sentence probably owns one of the square cookie crumbs. This is because chips the core of every electronic system – from smartphones to cars to washing machines – are created on wafers. However, the wafer in the picture is a very special specimen: a template for quantum computers.

A wafer with micro LED chips. Each square is a chip. Picture credits: Jan Gülink/TU Braunschweig

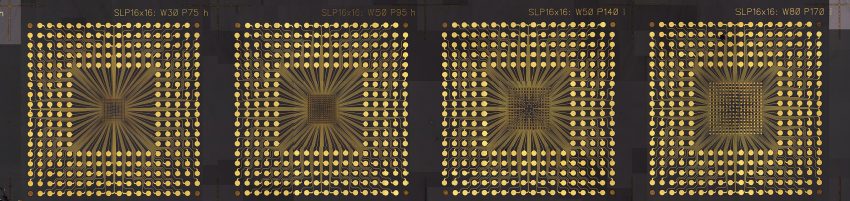

Quantum computers need many small and simultaneously precise light sources. At least if you want to build an ion trap computer, such as the Quantum Valley Lower Saxony (QVLS) – a research consortium including the TU Braunschweig, the Physikalisch-Technische Bundesanstalt and the Leibniz University of Hanover – is planning. The light controls the so-called qubits, the smallest computing units of the quantum computer. Each qubit gets its own light source. With a QVLS target of 50 qubits by 2025, 50 light sources are therefore required – and this within the space of this letter: Q.

The picture of the month shows the pioneer for the light chip of the future quantum computer, a wafer with micro LED chips. The LED platforms already meet many of the requirements: They consist of the right semiconductor material, accommodate sufficient light sources in a small space and are potentially suitable for mass production. In fact, the image of the quantum computer wafer would look exactly like the picture of the month to humans. Only under the microscope would the difference be visible.

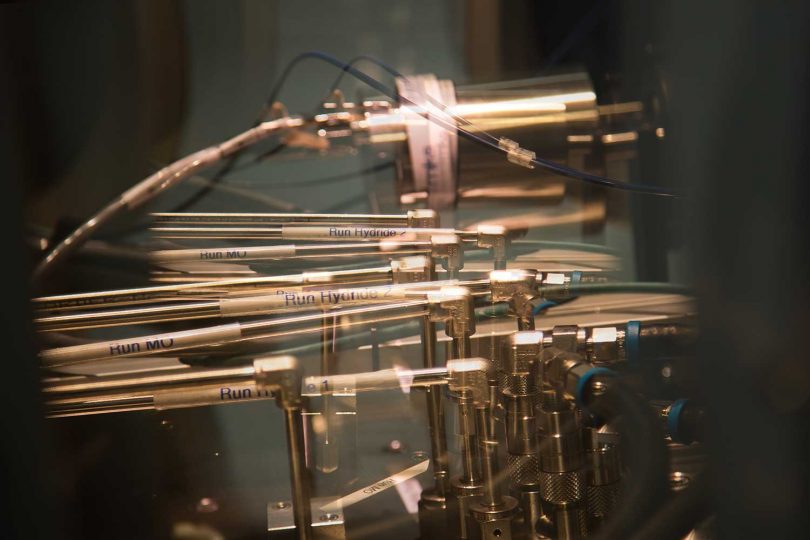

All this is backed by many years of expertise. For example, the Institute of Semiconductor Technology with its “Epitaxy Competence Center – ec²” has all the equipment needed to manufacture chips. In addition, the QuantumFrontiers cluster of excellence, with research groups such as ‘Nano Light’, performs basic research that now benefits the quantum computer.

From an LED to a laser beam

For a quantum computer, however, the LED chips must be further developed. Their light scatters too much in the width and the wavelength is ‘only’ accurate to a few nanometers. Therefore, the scientists at the research consortium have to focus the LEDs into lasers: Micro-LEDs will then become so-called surface emitters. To turn LED light into laser light, several mirrors inside the chip manipulate the light until only a very narrow beam of a precisely defined wavelength is left. These optical components are applied directly in the manufacturing process in several layers to the wafer of the light-emitting LED. Each layer is just one hundred nanometers thick, adapted to the desired wavelength. This is so small that only the high-resolution electron microscope TEM can adequately inspect the mirrors. It’s a good thing that the microscope is available only 100 meters away, in the Laboratory for Emerging Nanometrology (LENA).

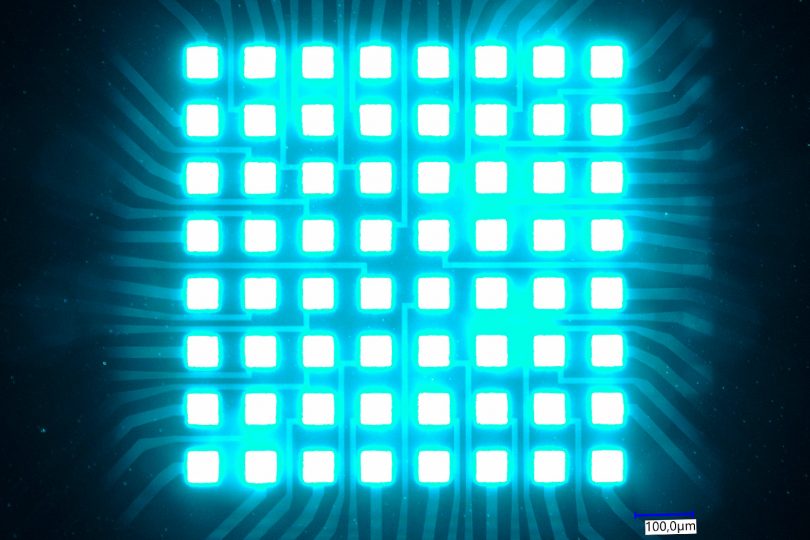

- A single chip in detail. The ultra-thin conductor paths connect the microscopic LEDs with macroscopic electronics. Picture credits: Jan Gülink/ TU Braunschweig

- As soon as the LEDs light up, the difference to the planned chip for quantum computers becomes apparent. Because the light still shines in all directions. Later, each light source will form a fine beam. Picture credits: Jan Gülink/ TU Braunschweig

A team effort

To ensure that the correct wafers for quantum computers are produced at the Institute of Semiconductor Technology (IHT) at TU Braunschweig, scientists from the various disciplines of QVLS have to act in concert. For example, precision lasers are already available at Leibniz Universität Hannover, but only as laboratory setups. The goal at IHT is therefore to realize lasers on a chip size and thus make them scalable. The integration into the planned quantum computer, on the other hand, will not be possible without the expertise of the Physikalisch-Technische Bundesanstalt in the field of sensitive qubits.