Nanowire power plant Microscopic energy solution for implantable biosensors from the Institute of Semiconductor Technology

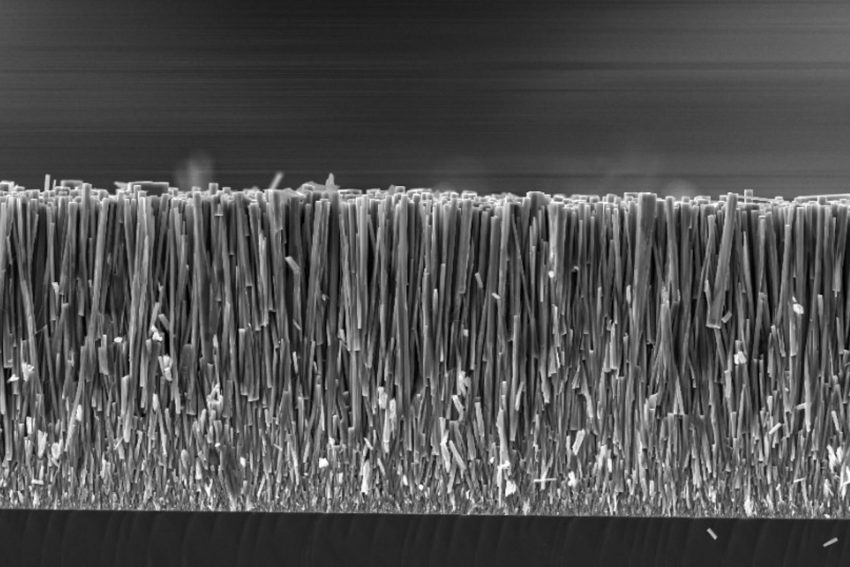

The zinc oxide nanowires have grown to a remarkably high and slender length. For doctoral student Frank Anang, this is an impressive milestone on the way to producing an efficient power plant in the smallest of spaces from these brush-like structures. The energy generation is based on the so called piezoelectric effect, in which voltage is generated when a solid is elastically deformed. The amount of voltage generated in Anang’s nano power plant largely depends on how long and thin he can grow the nanowires at the LENA Research Centre at TU Braunschweig.

Viewed from the side, the nanowires are similar to a brush – except a white blood cell would stand taller. Covered with fitting gold plates as electrodes at the top and bottom, they can translate a compressive force into a small voltage. Picture credits: Frank Anang/TU Braunschweig

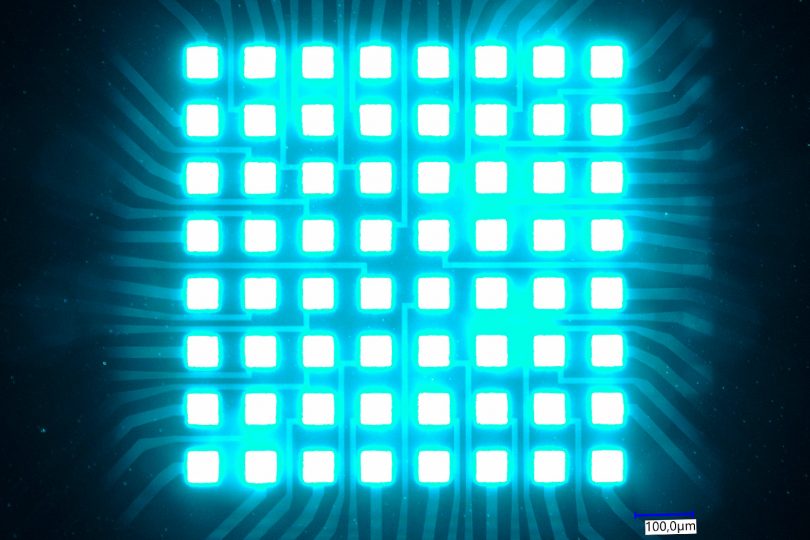

The latest wires shown in the picture above are just over 26.8 microns long and 0.65 microns thick – about the length of a white blood cell, while being more than a hundred times thinner than a human hair. They generate a voltage of circa 95.6 millivolts. Just enough to operate a tiny sensor or memory. Even a low-current LED might glow dimly. All they need is a little pressure. In this case, an external compressive force of roughly 0,9 Newton, or in other words: the force needed to lift a chocolate bar. Embedded in an insulating polymer and covered with bottom and top gold plates as electrodes, these nano power plants can be used in wearable energy harvester devices and self-powered sensors, such as implantable biosensors for adaptive pacing.

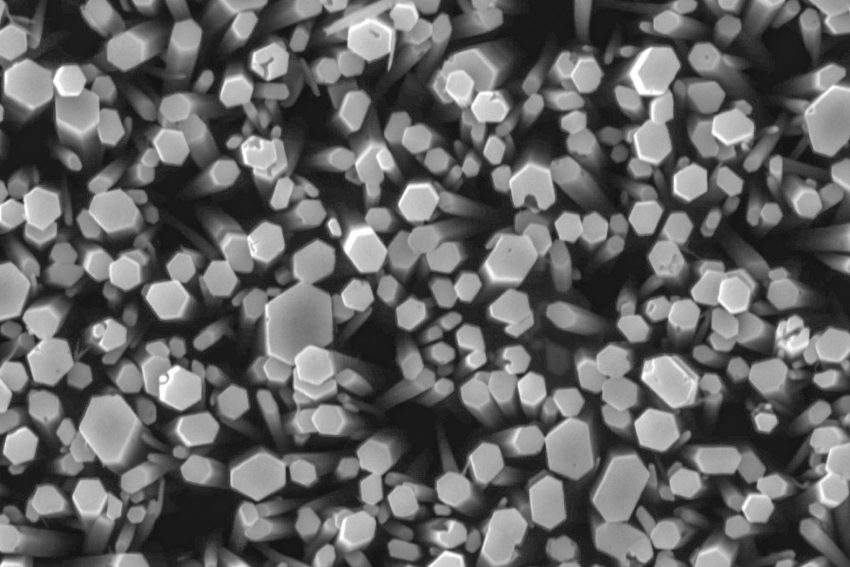

From above, the hexagonal crystal structure of the nanowires is clearly visible. The thinner the wires grow without breaking, the better the potential power generation. Picture credits: Frank Anang/TU Braunschweig

PhD in the international metrology network

Doctoral student Frank Anang is part of the international exchange and support network of National Metrology Institutes. In his case the connection between Germany and Ghana. Picture credits: Annika Hinze/TU Braunschweig

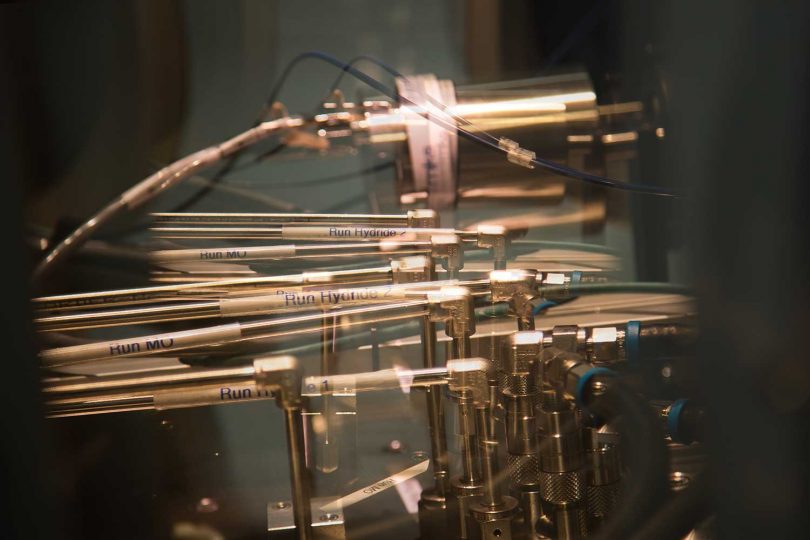

For Frank Anang, this is the central part of his doctoral project at the Braunschweig International Graduate School of Metrology (B-IGSM), the joint graduate school of TU Braunschweig and the National Metrology Institute of Germany (PTB). Thanks to the PTB’s international cooperation, he was able to start his research at the Institute for Semiconductor Technology at TU Braunschweig with support from the Federal Ministry for Economic Cooperation and Development. After completing his doctorate, he will contribute the expertise he has acquired in the field of metrology to the National Metrology Institute in his home country of Ghana.

Frank Anang: “My PhD research leverages my metrology expertise to develop and quantitatively validate energy-harvesting devices, enabling reliable, self-powered systems that are grounded in traceable measurement science. I would especially like to thank my collaborators at LENA, Braunschweig’s Institute for Particle Technology, the Physikalisch-Technische Bundesanstalt, Electrosciences Ltd (UK) and Quantum Design Microscopy GmbH.”