Ice Cold and Filled With Bobbins Interview with a large equipment: The MPMS

The Magnetic Property Measurement System (MPMS) uses superconducting sensors to detect the magnetic moment. But what exactly is hidden in the coils of this large equipment at the Laboratory for Emerging Nanometrology (LENA)? Our external editor Dörte Saße asked – specifically, she asked the device.

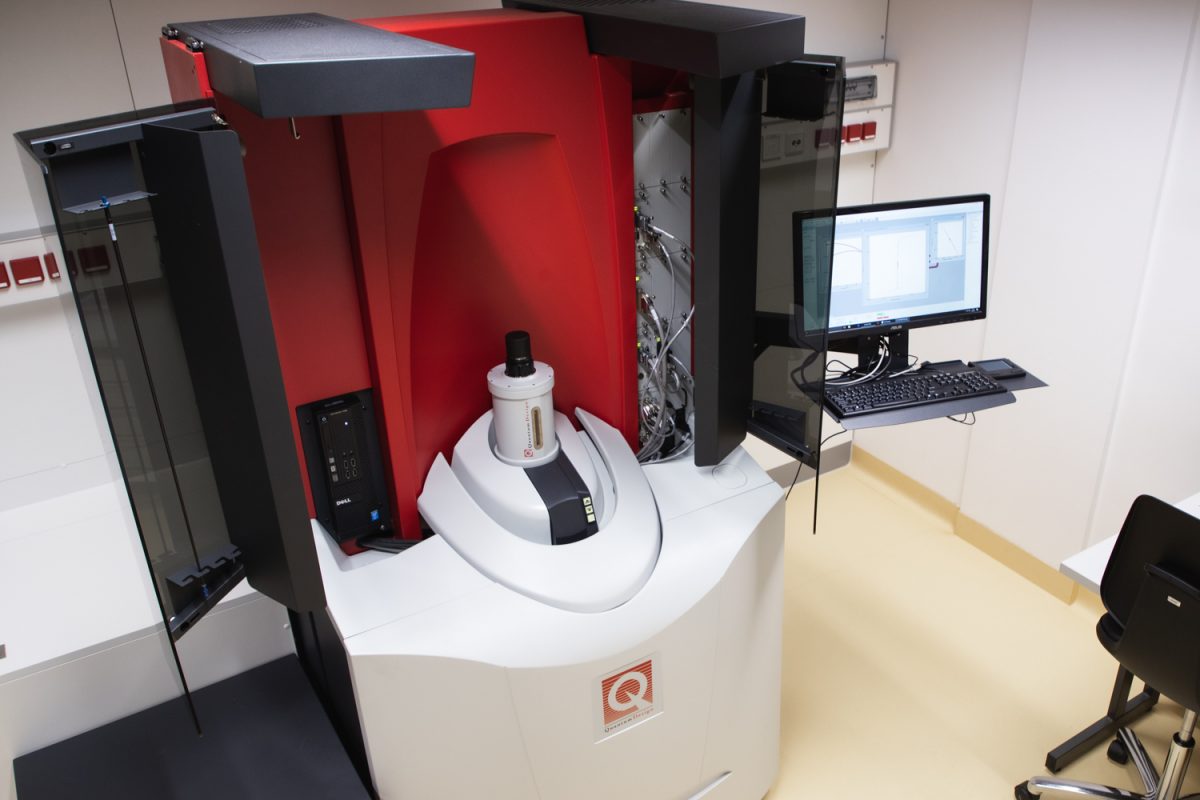

MPMS: “This is me – from my good side. Picture credits: Max Fuhrmann/TU Braunschweig

Good morning, MPMS, how would you describe yourself and what do you do anyway?

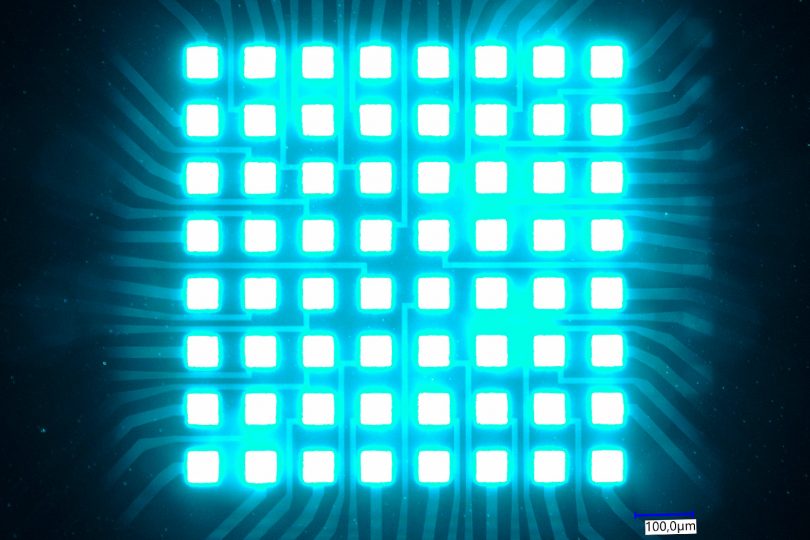

Moin Moin! “Magnetische Eigenschaften Mess-System” is my translated name – and that says it all. I get a sample of nanoparticles between the coils, move it up and down a little and my sensor team measures its magnetic moment. In technical jargon: the lowercase “m”. No matter whether it’s paramagnetic, diamagnetic, ferromagnetic or superparamagnetic. Whether as powder, in solid matrix or in liquid: Give me your samples, I can tickle out everything about their magnetic properties from any material.

But isn’t that a bit full-bodied? They say you are pretty straightforward?

Well, yes. For the fact that magnetism in all its varieties is quite complex, I’m actually simply constructed: A few coils, a few sensors and a small, precise transport motor – that’s basically enough. However, the sensors, called SQUID, are a marvel of technology. They must always be kept ice-cold. Helium cold, to be precise. SQUID is in fact the English abbreviation for “superconducting quantum interference detector”. Only when it is cold enough do the sensors work superconductively and can detect extremely weak magnetic field changes very precisely. That’s why my lower half is basically a big thermos flask with technology inside and around it. The connected analysis computer helps to find out the magnetic moment and other details.

This “m” by the way, i.e. the magnetic strength and orientation of an object – not only magnets possess this, but also moving elementary particles like protons and electrons. And thus also various molecules that are made up of them. Incidentally, the ancient Greeks had already discovered these “strange stones” on which nails and other iron got stuck – they named them Magnisia after the Greek landscape. Today, the ferromagnetic mineral is called magnetite and can be found around the world. The Chinese used it as early as a millennium ago to determine the cardinal direction. I use a similar effect in my inner life, if the coil was the earth’s magnetic field and the nanoparticle the compass needle…

How does such a measurement run work?

I always measure a signal change – the change caused by the moving sample. So, my excitation coils first build up a constant magnetic field. Then my motor pushes the material on the sample holder up and down within the two pairs of coils. And this movement – who remembers induction from school lessons? – changes the magnetic flux, causes a current in the coil pairs: sometimes stronger, sometimes weaker, depending on the position of the sample in the coils. This in turn is registered by the SQUID sensors, again by induction, and finally outputs the measurement curve. From this, the computer can calculate the magnetic moment of the material. Does that sound complicated? Because this is only the simplest application…

By the way, my humans adjust the measuring mode depending on sample and problem: sometimes, for example, my engine moves the sample up very slowly, for more than four seconds; but I can also shake it quickly, up to 16 times per second, which I do for four seconds. During this time we record a data point. And so if we record a whole magnetisation curve with 61 points, it takes a little over a quarter of an hour. But as Einstein said? Everything is relative. So it can also be slower or longer, because there are so many parameters you can set on me.

And what is special about you here at LENA?

I just work in so many different ways. I can increase my static magnetic field to 7 Tesla, which is the flux density of around 700 refrigerator magnets. But I can also create very small fields. Or very fine intervals. I also manage sample temperatures between 1.8 and 400 Kelvin, i.e. near absolute zero to almost 130° Celsius – because some materials change their magnetism when heated. And on top of that, my coils not only swallow direct current, but also alternating current – because with alternating fields we can also observe dynamic processes. That is, how quickly the particles change direction when the field direction changes: In this way I can help determine even more particle properties. Or I can also detect viruses in a so-called bio- or immunoassay. Other devices in Braunschweig also work with such alternating fields – but I am the only one that can combine these fields, very low frequencies and a broad temperature spectrum. And really accurate measurements.

What is special about me? The best was saved for last: My liquid sample holder is absolutely unique, because it is a self-construction! It was designed here in Braunschweig and constructed right in our workshop. With liquid samples it is important that they are not drawn into my vacuum chamber, the previous sample holder was not leak-proof. But now, in principle, you only have to screw two tubes together, that works great and simplifies the work enormously.

With all the great features and capabilities – do you have any quirks?

Well, quirks… I have to correct a few things, just like many of my machine colleagues. For example, the background signal has to be calculated out, or the geometry of the sample has to be taken into account. If it is a liquid sample, I have to ignore the signal of the water. And my calibration runs with a palladium sample that is always the same. But if the sample is narrower or longer, that changes the signal in some way – you always have to take that into account.

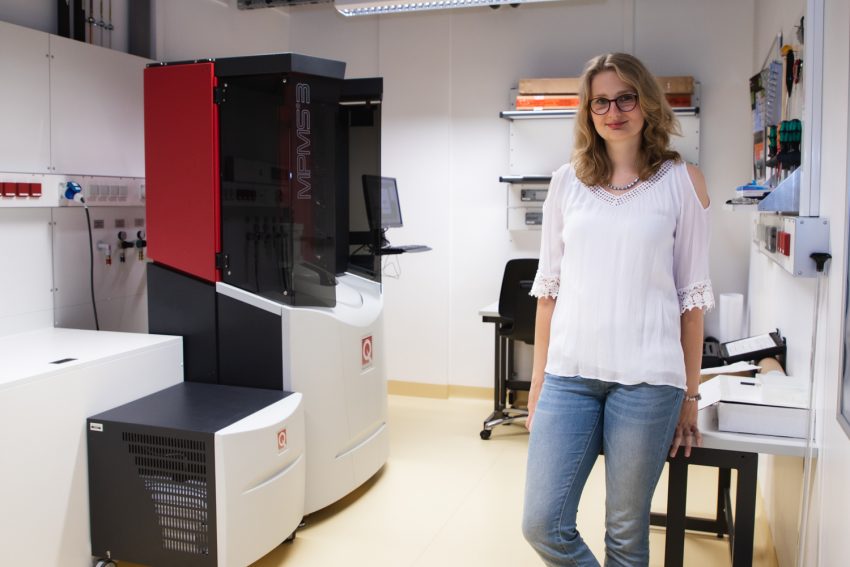

MPMS: “On the right, in front of me, is Tamara Kahmann, who also did the interpreting for me. As a doctoral student, she is currently with me very often. Professor Frank Ludwig and Enja Rösch are also part of the team. A virus is currently preventing them all from being able to be in the photo. Hopefully it’s not a Trojan horse. Photo credits: Max Fuhrmann/TU Braunschweig

And how long have you been in Braunschweig? Do you like it here?

I was brought here about two years ago, quite completely from my mother factory – and simply set up. Turnkey, so to speak. There’s my main element, large as an oversized refrigerator, light grey at the bottom, anthracite and red at the top. Next to it is a box with the pump. This is connected to a compressor and to the helium containers in the next room for cooling. In itself I feel quite comfortable here. I get to feed very different samples. Master and doctoral theses have been and are being worked on. Basic research and support for future generations of researchers, what more could you want?

Author: Dörte Saße