Hydrogen in the Tank Low-emission and efficient hydrogen engines drives of the future?

Are there other alternative drive concepts besides battery and fuel cell that enable climate-neutral mobility? Can the already known technology of the hydrogen engine complement these two? For which area of application is such a drive suitable? The hydrogen combustion engine is still an outsider in the mobility of the future, but it has potential as an alternative drive – for example for use in heavy commercial vehicles such as trucks, agricultural and construction machinery. A research team from the Institute for Internal Combustion Engines (ivb) at Technische Universität Braunschweig, led by Professor Peter Eilts, is also convinced of this.

The hydrogen combustion engine is an outsider in this race, but has a lot of potential. Photo credit: Lukas Sagan/Institute of Internal Combustion Engines

What is a hydrogen engine and how clean is it?

A hydrogen engine is an internal combustion engine that runs on hydrogen as fuel and directly generates a mechanical rotary motion, as in classic petrol or diesel engines. A hydrogen engine is therefore not to be confused with the technology of a fuel cell, in which the chemical energy of the hydrogen is first converted into electrical energy with the help of oxygen, which in turn drives an electric machine. If the hydrogen comes from renewable sources, hydrogen engines can contribute to climate protection. This is because hydrogen burns without CO₂ emissions.

“The technology is not new,” says Professor Eilts. “Twenty years ago, manufacturers already put the first vehicles with hydrogen engines on the road in small series. But the technology failed to make a breakthrough – partly because there was no hydrogen infrastructure.” As a result of the worsening climate change, the topic of hydrogen as a fuel is now more present than ever. The innovation laboratory “Sustainable Hydrogen Combustion Concepts”, funded by the Lower Saxony Ministry of Science and Culture, is pursuing the overarching goal of using innovative measures to make hydrogen combustion so low-emission that it is fully equivalent to other hydrogen utilisation paths from an ecological perspective.

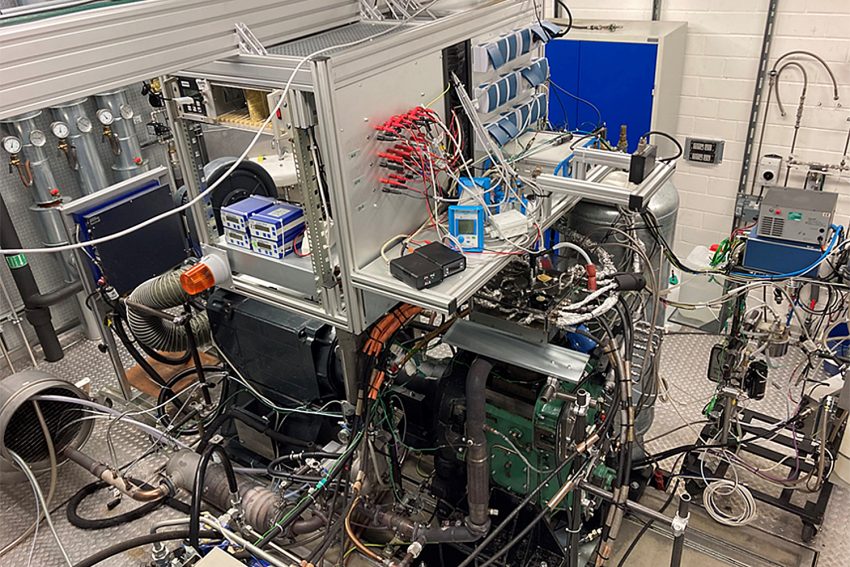

The test bench and the periphery of the single-cylinder research engine are converted for operation with hydrogen. The variable valve train developed by the Institute is used in combination with exhaust gas recirculation and water injection – as an innovative measure for efficient hydrogen combustion. Photo credit: Marius Betz/Institute of Internal Combustion Engines.

Internal engine solution instead of exhaust gas aftertreatment

In the sub-project “Low-emission and efficient hydrogen engines”, the ivb research team is developing an efficient combustion process for this purpose on a single-cylinder commercial vehicle research engine. “In classic hydrogen engines, nitrogen oxides (NOX) are filtered out by means of exhaust gas aftertreatment. However, these systems are complex and cost-intensive,” says Nico Höweling, a research associate at the ivb. “We take a different approach and favour a high dilution concept. By means of strong leaning, water injection and exhaust gas recirculation, NOX emissions are to be lowered so significantly that emission limits can already be met within the engine.”

How does this work? “In lean-burn operation, the engine works with a lean fuel-air mixture, i.e. with relatively low fuel content in relation to the air,” explains Lukas Sagan, research associate at the ivb. There is a significant excess of combustion air in the cylinder, which causes the combustion temperature to drop. “A low combustion temperature in turn has the effect of reducing the proportion of nitrogen oxides in the exhaust gas.”

Slowly approaching the limits of ignition capability

On their test engine, the research team also wants to use a fully variable valve train, water injection and cooled high-pressure exhaust gas recirculation to determine the limits of the hydrogen’s ignition capability in experimental and simulative investigations and thus analyse combustion anomalies – this is also a challenge in the project. Sagan: “Hydrogen is very reactive and explosive. We want to avoid self-ignition at all costs. We will therefore slowly approach the limits in our experiments.” Currently, the ivb research team is in the process of converting the test stand. The experimental test series is scheduled to start in May 2022.

The researchers want to realise an increase in the specific power of the engine with simultaneously low NOX emissions by means of an innovative, efficient and compact high-charging system. “In the research network, we are bundling our competences and can thus implement the numerical development of such a turbocharging system, which provides the required boost pressure, in the best possible way,” says Professor Eilts. In doing so, the scientists benefit from their experience from research projects that have already been worked on in cooperation between the ivb and the Institute of Turbomachinery and Fluid Dynamics (TFD) at LUH, for example in the projects ATL for lean concepts and exhaust pulsation and turbocharger interaction.

Known technology, no costly conversion

Eilts and his team see hydrogen engine technology less as a competitor to electric cars and vehicles with fuel cells, but rather as a complement to alternative forms of drive. Especially for large, heavy vehicles that have to cover longer distances, the hydrogen engine scores points compared to batteries and fuel cells. In addition, the criterion of time-to-market – i.e. the time from product idea to market maturity – speaks in favour of hydrogen engines. “The technology of combustion engines is well known, vehicle and engine manufacturers have the corresponding know-how, and a costly conversion of the engine is not necessary,” says Professor Eilts.

The only bottleneck: In order for vehicles with a hydrogen engine on board to shed their outsider role and take off on the roads, there needs to be enough “green” hydrogen and a nationwide network of hydrogen filling stations.

About the Project

In the research project “Low-emission and efficient hydrogen engines”, led by Leibniz Universität Hannover (LUH), the team from the Institute of Internal Combustion Engines at TU Braunschweig is working together with scientists from TU Clausthal and Jade Hochschule Wilhelmshaven as well as with partners from the industrial sector. The sub-project is being funded for three years with a total of 1.2 million euros from the Lower Saxony Ministry of Science and Culture.