Battery research: PhD Students Study “Black Mass” New research training group on the sustainable closed-loop production and use of lithium-ion batteries

The mobility turnaround is accompanied by a steadily increasing demand for lithium-ion batteries. The consistent recycling of raw materials to increase sustainability in the electromobility sector is crucial for the future: This is conditioned by resource availability, raw material costs as well as socially critical factors in battery raw material mining countries. In particular, the recovery of active battery components such as lithium nickel cobalt manganese oxide (NCM) is highly relevant from an ecological and economic perspective. According to the current state of research, these components can only be recovered in the required purity and long-term recycling rate with a very high effort in circular battery production. For this reason, this topic will be studied in greater depth in a new research training group starting in October 2021. The PhD students will be recruited starting in March.

Scientists at the Coperion extruder with die and extrudate at the BLB. Picture credit: Marisol Glasserman/TU Braunschweig

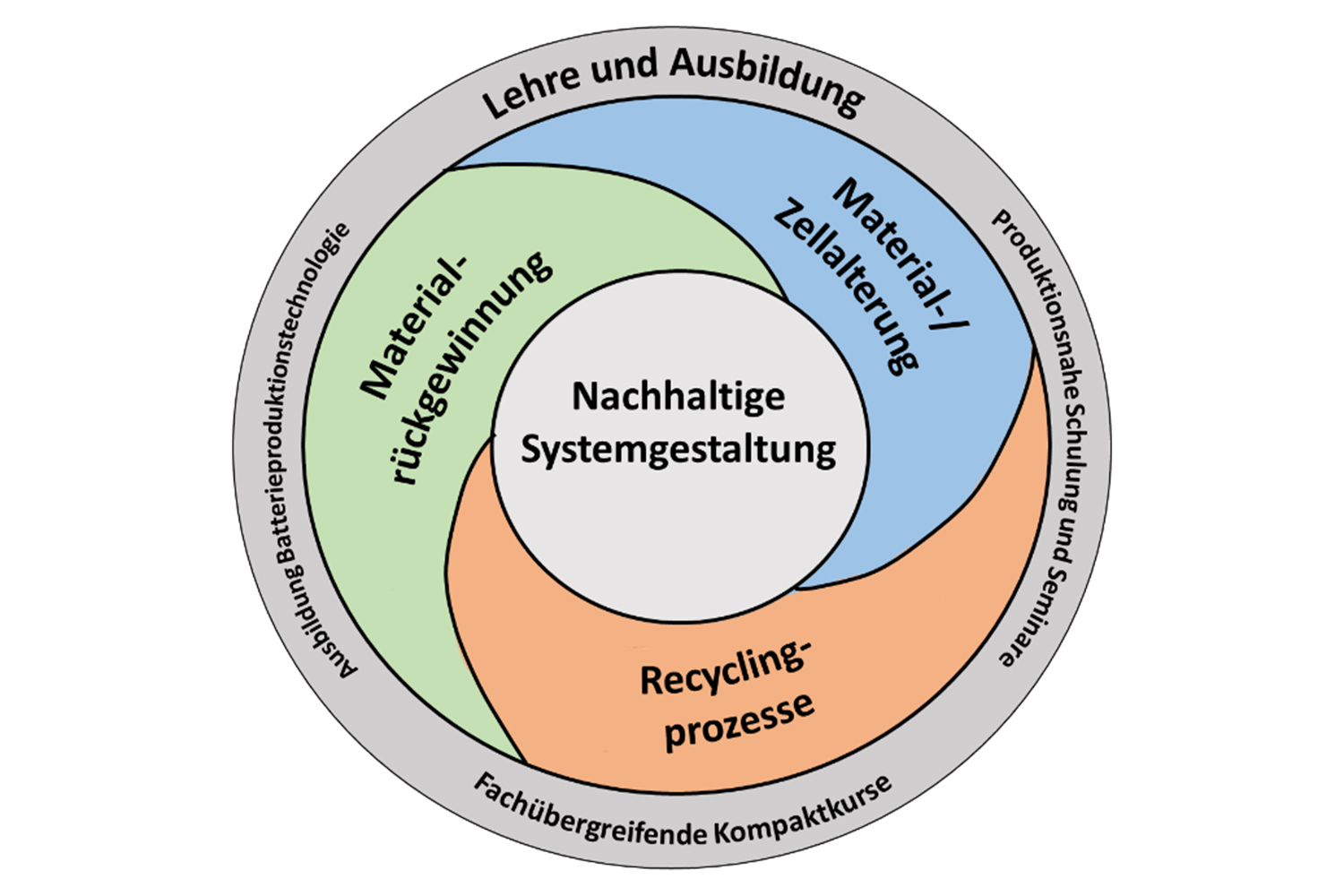

The new Research Training Group “Life Cycle Production and Utilization of Lithium-Ion Batteries” is dedicated to scalable, economically efficient and ecologically sustainable process technologies. This includes diagnostic and simulation methods along the material, production and recycling cycle of lithium-ion batteries. The central research field is sustainable system design (see figure), consisting of life cycle considerations, economic/ecological assessment and the development of a data-driven approach to establish a sustainable circular economy.

The PhD students are working on issues that interlock at the individual process interfaces, thus allowing a holistic and coordinated mapping of the battery material cycle management and its systematic research.

Graphic: Sustainable system design is the central research field of the new research training group of TU Braunschweig, TU Clausthal, Leibniz Universität Hannover and Fraunhofer IST. Picture credit: BLB/TU Braunschweig

The intended studies on recycling will be divided into three research fields: Material/Cell Aging, Recycling Processes, and Material Recovery. In all areas, these will be complemented by strong analytical method development and use to understand process-structure-property relationships.

Cell material recycling and black matter processing.

In the usage phase, material and cell aging of recycled cell materials are investigated. Subsequently, the cells are introduced to the renewed recycling process – with a focus on the disassembly and the mechanical/thermal process steps. The obtained black mass (mixture of anodes and cathode active material) is then formed into active materials for renewed use in lithium-ion batteries by hydrometallurgical steps (cathode material) as well as temperature application (anode material).

The Research Training Group also offers doctoral students the opportunity to conduct interdisciplinary research in a key technology area with subject-specific and interdisciplinary support. At the same time, the PhD students are prepared for tasks in diverse industrial and research institutions.

The consortium

The interdisciplinary collaboration of natural sciences, material sciences, engineering and economics is the central approach of the consortium in order to realize a more profound and well-founded research on battery material cycle management. In the cross-locational research training group (spokesman Professor Arno Kwade) 19 scientists from the TU Braunschweig, TU Clausthal, Leibniz Universität Hannover and Fraunhofer IST are working together.

In addition, Professor Petr Novák will be involved in the research training group within the framework of a senior professorship at the Institute of Energy and Process Systems Engineering (InES) in order to support the PhD students with his many years of experience in the field of material characterization, aging of active materials and battery cell system understanding. In addition, the procurement of pilot plants for the recycling of battery materials, especially their recycling, is supported.

The overall project will start on 1 March 2021 with the recruitment of the PhD students, who are expected to start actively in the college in October 2021, and will end in February 2025. The grant is provided by the Ministry of Science and Culture (MWK) and the Volkswagen Foundation.