Additive Manufacturing in Construction (AMC) – The Challenge of Large Scale DFG funds new CRC/Transregio at Technische Universität Braunschweig in collaboration with Technical University of Munich

Additive Manufacturing (3D printing) is a new manufacturing technology that is now introduced in many industrial sectors. If the potential of this technology is transferred to the large scale of construction, new design possibilities and more efficient, resource-saving construction methods can be created. The aim of the TRR 277, funded by the German Research Foundation (DFG), is to fundamentally investigate Additive Manufacturing in interdisciplinary research for the implementation into construction industry. The DFG is establishing a total of ten new Collaborative Research Centres to strengthen cutting-edge research at universities. Starting on 1 January 2020, they will initially receive a total of around 101 million euros in funding for four years.

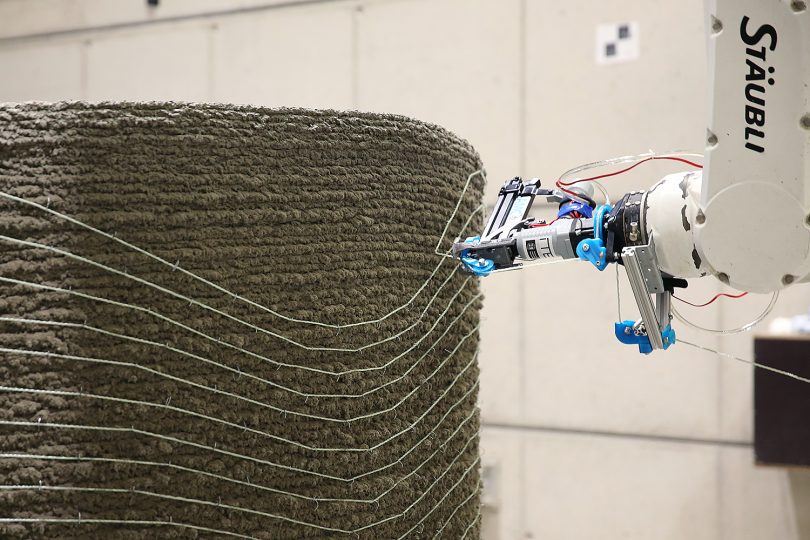

The basic principles of Additive Manufacturing are based on digitally controlled layer-by-layer component design, without any mould making or forming processes. “This represents a paradigm shift to the predominantly manual construction techniques, which promote simple element forms and inefficient material utilization,” says the designated spokesperson Professor Harald Kloft of the Institute of Structural Design at the TU Braunschweig. Against the background of the enormous demand for resources in the construction industry with its significant contribution to global CO2 emissions, this novel technology will provide an efficient use of material.

“Great news – for a project in which scientifically outstanding colleagues are working in an exciting field for research,” says Professor Anke Kaysser-Pyzalla, President of the TU Braunschweig. “I am proud of the team effort across the borders of TUM and TU Braunschweig and look forward to further cooperation on an issue that is highly relevant to society and the economy”.

“I am particularly pleased with the positive assessment of the transregional project,” said Professor Peter Hecker, Vice President for Research and Young Scientists at the TU Braunschweig. “The SFB/TRR is an award for our research focus ‘City of the Future’ and contributes to raising the profile of civil engineering at the TU Braunschweig”.

The two universities, TU Braunschweig and TUM, have been working together for many years in various fields of engineering disciplines and in particular in the field of Additive Manufacturing. Due to the excellent equipment with large-scale research facilities at both locations, a wide variety of material-process combinations can be investigated right from the beginning.

The TRR 277 promotes the future strategic orientation of both universities. Thus, the CRC/Transregio is integrated into the research focus City of the Future/Future City at TU Braunschweig and strengthens the action agenda TUM.additives of the TUM as part of the “Bavarian Additive Manufacturing Cluster”. The TRR 277 aims to contribute to the development of Additive Manufacturing as a key technology for the digitalization of the construction industry, with increased productivity and an efficient use of resources.

Collaborative Research Centres and Transregional Projects

Collaborative Research Centres enable innovative, challenging and long-term research projects to be carried out in a collaborative effort and are thus intended to serve as focal points and structures for the applicant universities. Transregional projects (TRR) are a variant of the classical Collaborative Research Centres. This enables universities in Germany to closely network and apply for and carry out research projects on fundamental issues across all locations.