3D Printed Optics Additive manufacturing of components for the manipulation of terahertz radiation

Terahertz waves are regarded as the hope for new technologies in medicine, communication and security technology. However, new optical components are the basis for this. Researchers at Technische Universität Braunschweig have produced so-called diffraction gratings using 3D printing. Their measurements have shown that the gratings enable systematic manipulation of high-frequency radiation. Optical components for terahertz waves can therefore be manufactured quickly and reliably and investigated in new applications. The results of the study have been published in the journal “IEEE Transactions on Applied Superconductivity”.

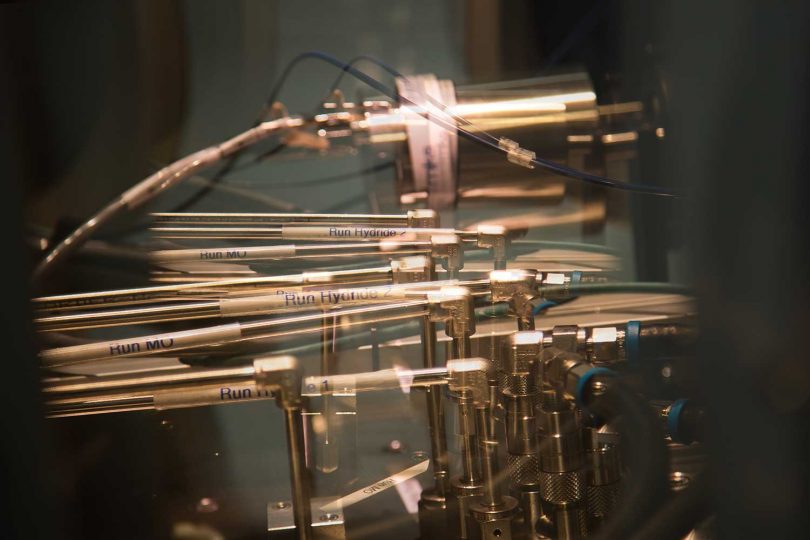

The diffraction gratings are five by five centimeters in size and their surface consists of periodically recurring structures. In order to be able to analyze the diffraction of the radiation, a precise manufacturing of the gratings is a prerequisite. For this reason, a stereolithography printer is used at the Institute for Electrical Measurement Science and Fundamentals of Electrical Engineering (EMG) at TU Braunschweig under the direction of Professor Meinhard Schilling. After printing, the diffraction gratings are coated with a thin gold layer: “This increases the reflectivity of the structures,” says Dr. Benedikt Hampel, who is investigating the optical properties of 3D-printed structures. In stereolithography, liquid photosensitive resins are solidified with a laser. This can be done with extremely high precision in the micrometer range. In this way, very precise plastic objects can be produced – quickly and reproducibly.

To improve the quality, the surface of the 3D-printed diffraction grating is closely examined: Scientists at the EMG examine their roughness and measure the diffracted radiation. A terahertz scanning microscope developed at the institute is available for this purpose, which records the radiation distribution three-dimensionally and makes it measurable.

Terahertz radiation

Terahertz radiation is an electromagnetic radiation whose frequency is above microwaves and below visible light. In the past, this frequency range was rarely used for technical applications due to a lack of sources and sensors. The comparatively high frequencies promise exciting application scenarios, for example as fast transmission technology in mobile radio communication and in medicine the analysis of tissue and breathing air. High-frequency radiation is used, for example, in the form of detectors at airports: radiation that is harmless to humans achieves good spatial resolution and can penetrate many non-metallic materials.

The Institute

The institute has been involved in the design and improvement of 3D printers for many years. Since 2016, the EMG has been supporting Fabmaker GmbH in its spin-off to make this technology available in schools. Since the summer semester 2019 the institute offers a lecture on additive manufacturing.

The further development of optical components is being promoted in the nanometrology research centre LENA (Laboratory for Emerging Nanometrology) and in the Institute for Electrical Measurement Science and Fundamentals of Electrical Engineering at TU Braunschweig together with the Physikalisch-Technische Bundesanstalt (PTB) and within the framework of the excellence cluster “Quantum Frontiers”.

Publication

Hampel et al., “Josephson Cantilevers for THz Microscopy of Additive Manufactured Diffractive Optical Components”, IEEE Trans. Appl. Supercond, Vol. 29, No. 5, 2019