From Zero to Terahertz in Three Years A short portrait of Marco Tollkühn from the NanoMet Research Training Group

In the NanoMet research training group, doctoral candidates measure ultra-small objects for technology, biology and medicine. The researchers in the group are looking for new approaches to measuring the smallest particles and thus pave the way for new technologies. Our volunteer Laurenz Kötter spoke with PhD student Marco Tollkühn about why it is beneficial to do a doctorate in the Research Training Group – especially if you are building a microscope without a blueprint.

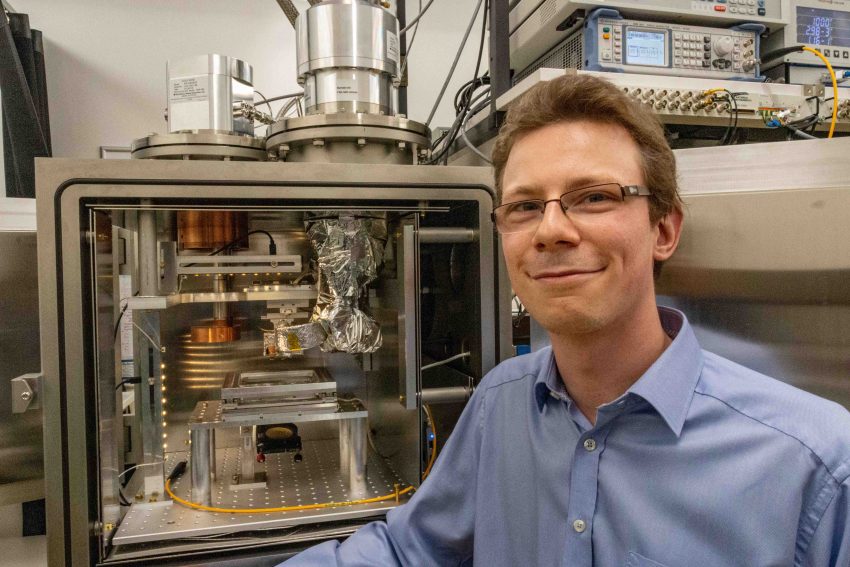

Marco Tollkühn in front of the opened vacuum chamber of the terahertz microscope. Picture credits: Laurenz Kötter/TU Braunschweig

Mr. Tollkühn, in your doctorate you deal with the terahertz microscope in the Laboratory for Emerging Nanometrology (LENA). What do you do there?

When I started, our laboratory at LENA was still in its shell. Now, three years later, the construction of the terahertz microscope is almost complete. I am currently correcting the last errors in the software, so that we will go into a kind of regular operation in the next few weeks. That means: measuring, without much trouble shooting.

My doctorate is mainly about the construction of the microscope. Although I will also publish first measurements in my doctoral thesis, the unique thing is the device itself. Except for our own prototype, there is nothing comparable worldwide. At the same time we are entering a hardly used frequency range of the electromagnetic spectrum: Terahertz radiation. So we are conducting basic research that could enable a new generation of computer chips in the future or beat data transmission of 5G tenfold.

How did you arrive at this extraordinary occupation?

In 2011, I started a Bachelor’s degree in Electrical Engineering at the TU Braunschweig and wrote my thesis at the institute of Professor Meinhard Schilling, who is now also supervising my doctoral thesis. At the time, I was still writing about 3D printing with Dr. Benedikt Hampel, who was also doing his doctorate at the NanoMet Research Training Group at the time. I worked with him on the idea of the terahertz microscope during my master’s degree. The prototype of today’s microscope was created in the rooms of the Institute of Electrical Measurement Science and Fundamental Electrical Engineering (EMG) – as a so-called “proof of concept” that proved the feasibility of the project. An application for a large-scale instrument for the emerging LENA made it possible to further refine the idea and to improve the adventurous prototype construction and implement it in LENA. I absolutely wanted to be part of it so I started my doctorate.

What role does the NanoMet research training group play in your doctorate?

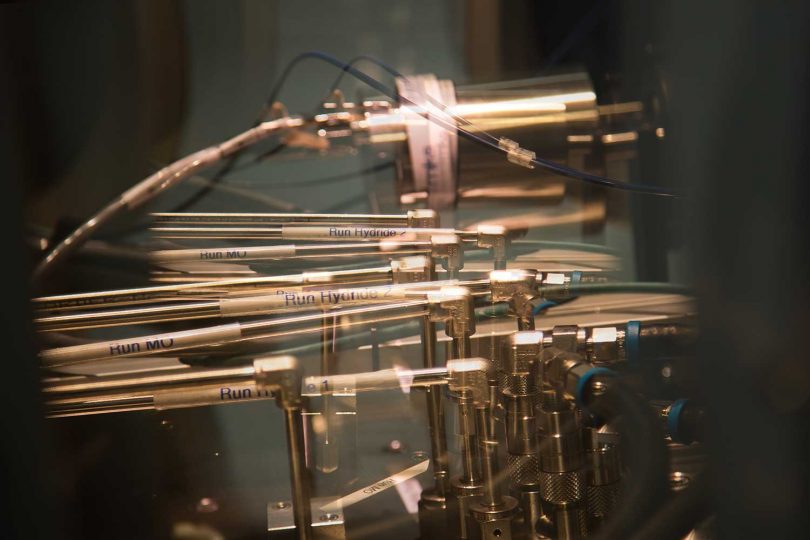

In the Research Training Group, we doctoral students all met twice a week in lectures before Corona. Even though this was unfortunately cancelled due to the current situation, I was always able to find people there to discuss the many aspects of my doctorate. Whether it was software, cooling or laser technology, the construction of the terahertz microscope gave rise to enough unfamiliar questions. For example, I had never built a vacuum chamber before and I am not a mechanical engineer. But in NanoMet, another doctoral student already had some experience in this and helped out. This was especially helpful for the unusual angular design of the microscope.

The Research Training Group also helps with material resources. These could be travel expenses for conferences or publication costs. But also hardware for setting up the equipment. The actual large-scale equipment application was submitted by a generation of doctoral students before me. At that time, no one knew that these parts could ever be missing. In addition, through NanoMet I have a second supervisor in Professor Uwe Siegner, who does not work at the TU Braunschweig, but at the PTB. This way I always get a second opinion from someone who looks at my topic from a different perspective.