3D printing in zero gravity Student initiative involved in DLR and ESA experiment

ERIG e.V., i.e. the “ExperimentalRaumfahrt-InteressenGemeinschaft”, is a student initiative of TU Braunschweig. In addition to building and launching experimental rockets and Mars rover demonstrators, the students are currently involved in developing the CREATE experiment to further explore the possibilities of manufacturing in space. With this experiment, the students are participating in the REXUS/BEXUS programme of the German Aerospace Center (DLR), the Center of Applied Space Technology and Microgravity (ZARM), the Swedish National Space Agency (SNSA), the Swedish Space Corporation (SSC) and the European Space Agency (ESA). The launch of the REXUS rocket will take place in March 2024.

CREATE team members. Photo credit: ERIG e.V.

The REXUS/BEXUS programme enables students to transport a scientific payload into space on board a sounding rocket. During the flight, the prepared experiments on board are temporarily in microgravity. This is of course particularly interesting for the young researchers, because it allows them to study the influence of gravity on certain processes. In the past years, ERIG e.V. has already successfully participated in the REXUS/BEXUS programme twice.

The current REXUS experiment is CREATE. CREATE stands for “Carbon REinforced Additive manufacturing Technology Experiment” and deals with fibre-reinforced 3D printing. The aim of the experiment is to investigate the influence of gravitational force on the process of fibre-reinforced 3D printing.

Improved material properties

In almost all 3D printing processes, a filament is melted and then extruded through a nozzle at a defined point. In fibre-reinforced 3D printing, carbon fibres are added to the molten filament to create a composite of carbon fibre and plastic. This improves the material properties – especially the strength – of the printed plastic and enables a more diverse use of 3D-printed products. In addition, this method is ideally suited for use in space due to its greater flexibility, resource efficiency and compact manufacturing setup.

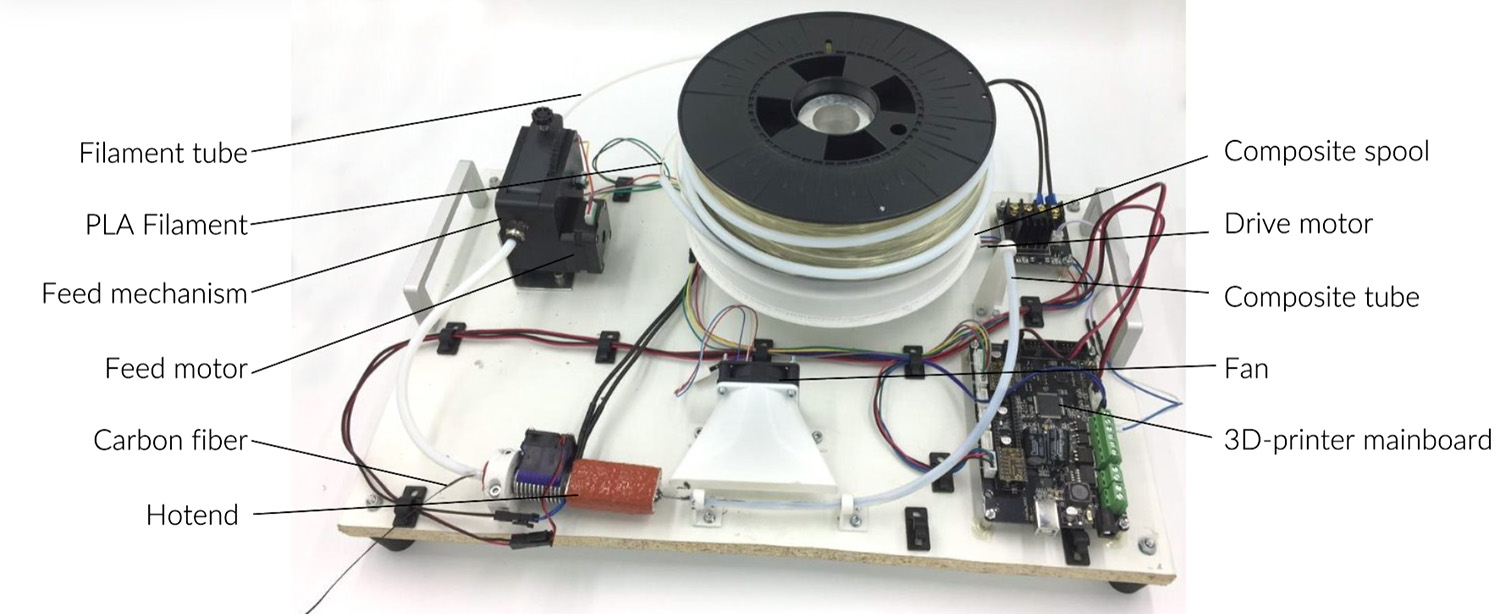

Current prototype of the CREATE experiment. Picture credits: ERIG e.V.

The problem: formation of voids

However, when carbon fibres and filament are extruded together, voids form at the fibre-matrix interface. These have a negative effect on the material properties of the composite. To improve composite manufacturing technologies, it is necessary to better understand the process of fibre-reinforced 3D printing and, in particular, the formation of voids.

Molten thermoplastic behaves like a non-Newtonian fluid, exhibiting a change in wettability under different gravity conditions. In zero gravity, the enclosure of the carbon fibres could thus be more uniform, improving the material properties, such as strength, stiffness and electrical conductivity, of the composite produced. To investigate this in more detail, the CREATE experiment will print fibre-reinforced composites on board a REXUS rocket in microgravity. In addition, the same setup will be used to produce composite samples on Earth at gravitational acceleration. The different composite samples will then be examined and compared with regard to their material properties.

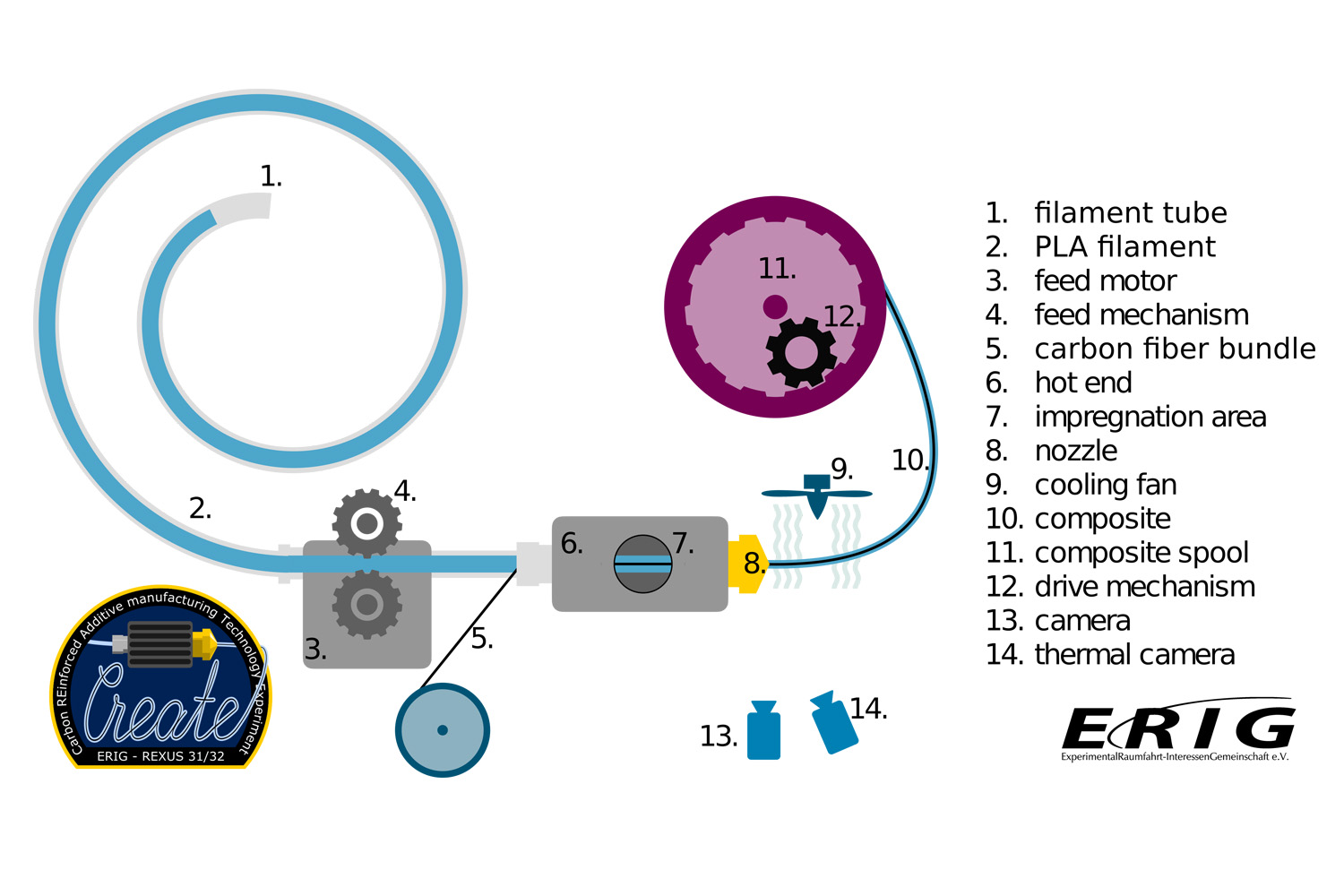

Schematic drawing of the functional design of CREATE: The plastic is melted in the hotend (6) and brought together with the carbon fibre (5). The composite material (10) is then printed, cooled and spooled. Picture credits: ERIG e.V.

CREATE is thus helping to pave the way for manufacturing in space by conducting important basic research in the relatively new field of fibre-reinforced additive manufacturing. Important aspects such as the effect of gravity on the strength of the composite, the density, the wetting of the fibres, the voids between filament and fibres, etc. can be efficiently evaluated and assessed by the experiment.